I Bar Steel Grating is widely used in various industries for its strength and durability. Understanding the I Bar Steel Grating Weight is essential for engineers, builders, and designers. This knowledge helps in making informed decisions, especially when it comes to load-bearing structures.

The weight of I Bar Steel Grating can vary based on several factors. The size, spacing, and thickness of the bars play crucial roles in determining the overall weight. Knowing the exact weight is vital for planning and logistics. It affects transportation costs and installation requirements.

In practice, many overlook the importance of calculating this weight accurately. Mistakes can lead to structural failures or excessive expenses. It is always wise to double-check calculations. Using precise measurements ensures safety and efficiency in projects. Understanding the I Bar Steel Grating Weight can ultimately enhance project outcomes.

I Bar steel grating is a popular choice in construction and industrial applications. It consists of a series of vertical bars known as I Bars, which provide strength and support. The I bars have a unique shape that maximizes load-bearing capabilities while minimizing weight. This efficiency is a key factor in its widespread use.

The composition of I Bar steel grating typically involves high-strength steel. This material offers durability and resistance to harsh conditions. It can withstand significant weights, making it suitable for various environments. However, the manufacturing process can sometimes result in inconsistencies. Not all I Bar grating has the same quality. Regular inspections can help in detecting such issues.

In addition to its structural benefits, I Bar steel grating is often used for drainage and ventilation. Openings in the grating allow for easy passage of air, water, and debris. This feature can enhance the longevity of surrounding materials. Yet, one must consider the specified load ratings and proper installation practices to avoid safety hazards. Understanding its definition and composition is crucial for effective use.

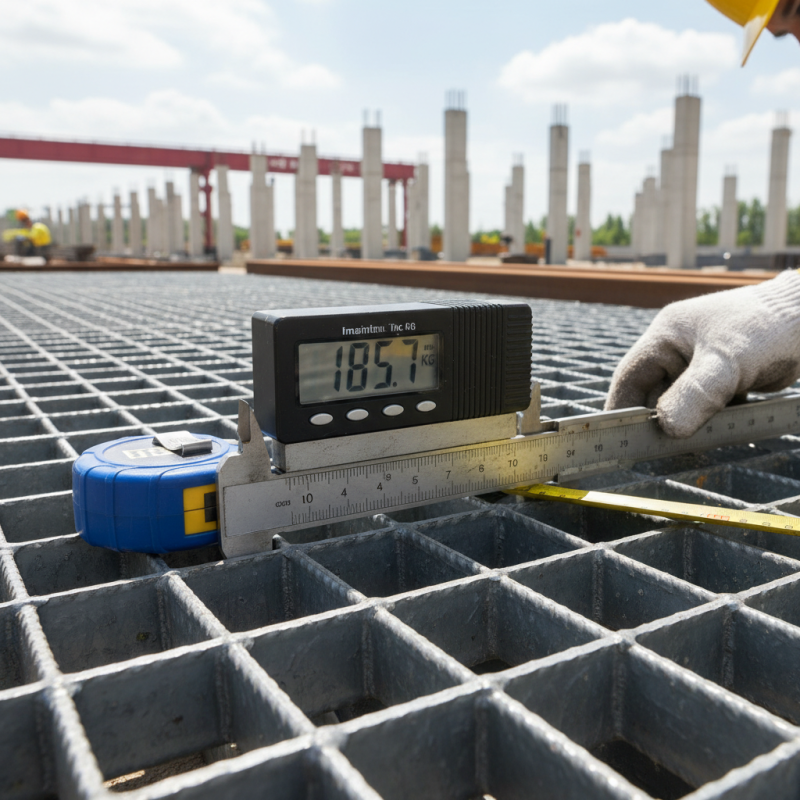

The following bar chart illustrates the average weight of different sizes of I Bar Steel Grating. The weights are measured in kilograms per square meter (kg/m²).

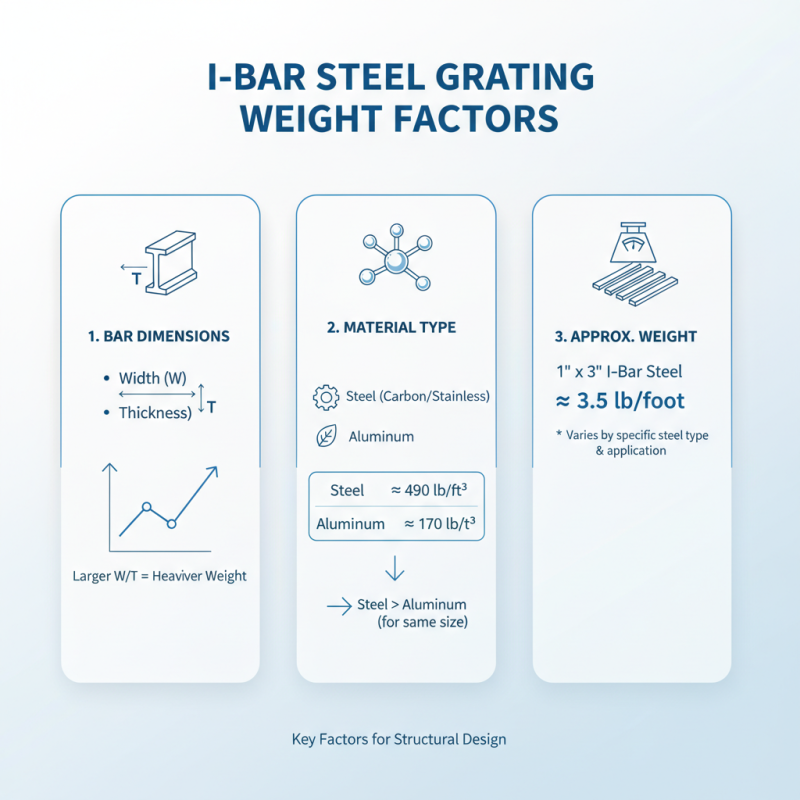

The weight of I bar steel grating is influenced by several key factors. The dimensions of the bar play a crucial role. A wider or thicker bar will naturally weigh more. According to industry standards, a 1 inch by 3 inch I bar can weigh approximately 3.5 pounds per foot. This can vary depending on the specific application and material type.

Material density is another factor. Steel, with a density around 490 pounds per cubic foot, contributes significantly to the overall weight. Sometimes, alloy mixtures can alter the density, which leads to weight differences. Data from structural analysis shows that variations in density can lead to weight changes of up to 25%.

Bar spacing is also essential. Closer spacing between bars results in increased weight. This can enhance load-bearing capacity. However, it is vital to balance between weight and functionality. Excessive weight can cause complications during installation. Ultimately, understanding these factors leads to better design and optimized performance in projects.

When calculating the weight of I Bar steel grating, it’s essential to consider several factors. The weight primarily depends on the dimensions of the grating and the material used. Typically, I Bar steel grating dimensions include the bar depth, spacing, and overall area. According to industry standards, the average weight can range from 40 to 200 pounds per square foot.

To calculate the weight, you can use a straightforward formula. Multiply the volume of the grating by the density of steel, which is approximately 490 pounds per cubic foot. For example, if you have a section measuring 2 feet by 3 feet with a depth of 1 inch, the volume is calculated as follows: 2 ft x 3 ft x 1/12 ft = 0.5 cubic feet. The estimated weight would then be 0.5 cubic feet x 490 lbs/cubic foot, giving you a total of 245 pounds for that section.

However, inaccuracies in measurement or assumptions about density can lead to miscalculations. Thickness variations or changes in material composition can also affect the final weight. This emphasizes the importance of precise measurements and adherence to manufacturing specifications. Regular audits and checks can help mitigate errors in the calculations.

I Bar steel grating has become a popular choice in various industries. Its unique design provides strength and stability, making it ideal for flooring and walkways. These gratings are crafted from high-quality steel, ensuring longevity and resistance to wear. Reports indicate that steel grating can support loads up to 1,500 pounds per square foot, making it suitable for heavy-duty applications.

In industrial settings, I Bar steel grating is frequently used in construction sites and factories. Its open design allows for better drainage and airflow, which is crucial in environments exposed to chemicals or heavy machinery. The versatility of I Bar grating extends to platforms and stair treads, contributing to workplace safety. Nevertheless, its installation requires careful consideration to prevent misalignment, leading to potential hazards.

While I Bar steel grating offers numerous advantages, there are challenges that users must address. The initial costs can be significant, and improper maintenance can lead to corrosion. Regular inspections are vital to ensure the integrity of the grating. Users must weigh these factors against the benefits to make informed decisions for their projects.

When comparing I bar steel grating with other types, several factors come into play. I bar grating typically features bars that have a constant width. This design allows for greater strength and less weight compared to traditional steel grates. However, it may not always be the best choice for every application. In some cases, the load-bearing capacity may fall short for heavy machinery.

Other types, like welded steel grating, often offer different advantages. They provide a flatter surface, which can be beneficial for specific flooring projects. Yet, they are generally heavier and may not fit every design requirement. The weight matters significantly when installation is considered. Transporting heavier grating can also complicate logistics.

While I bar grating is efficient, it may lack the versatility of other options. Sometimes that narrow profile can become an issue for personnel safety. An I bar could create a tripping hazard in busy areas. Recognizing these imperfections is crucial when selecting the right grating type. Each choice has its pros and cons, leading to continuous reflection on design needs.

| Type of Steel Grating | Weight per Square Meter (kg) | Load Capacity (kN) | Thickness (mm) |

|---|---|---|---|

| I Bar Steel Grating | 20 | 5.0 | 30 |

| Flat Bar Steel Grating | 18 | 4.5 | 25 |

| serrated Steel Grating | 22 | 6.0 | 32 |

| Heavy Duty Steel Grating | 25 | 8.0 | 40 |