Galvanized steel grating is widely used in various industries due to its strength and durability. Understanding its weight is essential for both construction and design applications. The weight of galvanized steel grating can vary significantly based on factors such as material thickness, spacing of the bars, and the overall dimensions of the grating panels.

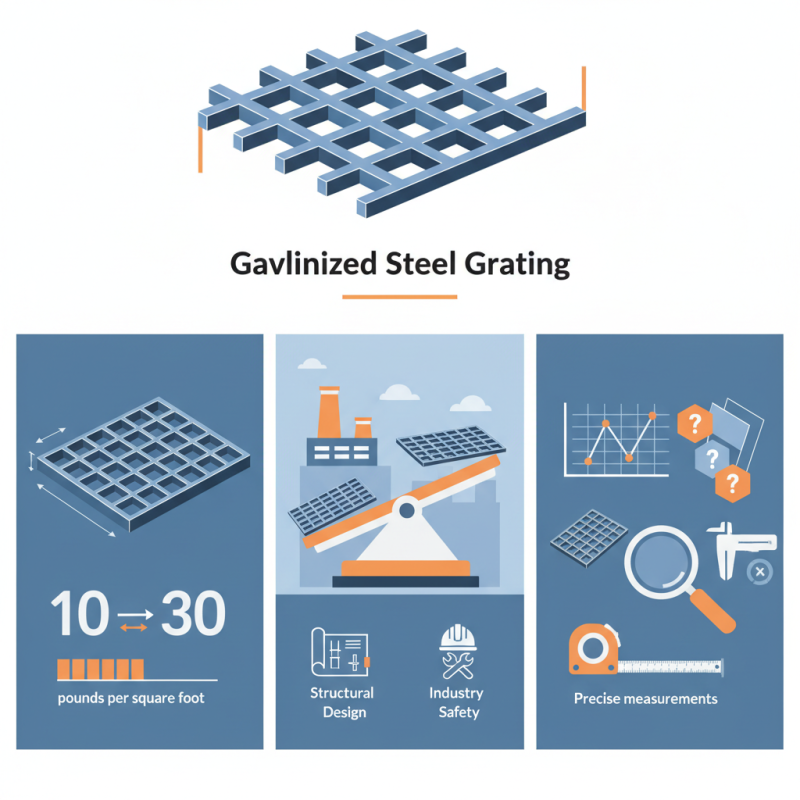

According to industry data, the standard weight range for galvanized steel grating is approximately 10 to 30 pounds per square foot. This variation is influenced by the type of grating, with heavier models providing more load-bearing capacity. The importance of knowing the "Galvanized Steel Grating Weight" lies in its implications for structural design. Accurate weight estimations prevent overloading and ensure safety in applications like walkways and platforms.

It’s worth noting that weighing galvanized steel grating is not straightforward. Quality control issues can lead to inconsistencies in manufacturing. Variations in the galvanization process can also affect weight. Thus, industry professionals often rely on standardized charts for estimates. Yet, these figures may not capture specific project needs or situations effectively. This raises questions about best practices and the necessity for precise measurements in real-world applications.

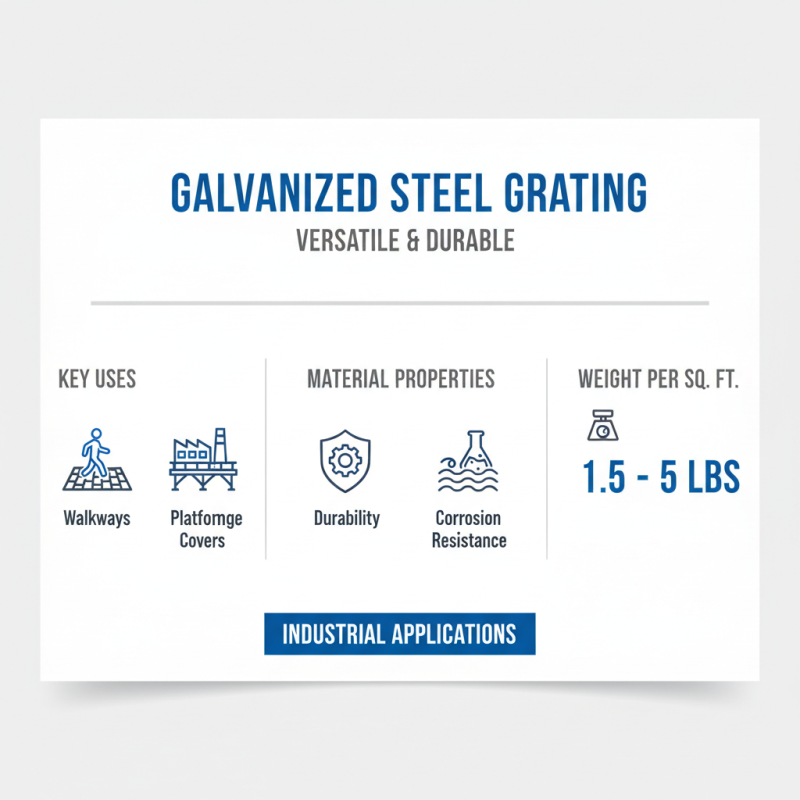

Galvanized steel grating is a versatile material widely used in various industries. It’s known for its durability and resistance to corrosion. Typically, galvanized steel grating is used in walkways, platforms, and drainage covers. The weight of this grating can vary based on its design, thickness, and spacing. According to industry reports, the weight per square foot often ranges from 1.5 to 5 pounds for most standard applications.

The applications of galvanized steel grating extend beyond construction. In industrial settings, it supports heavy loads while allowing for drainage and ventilation. The open design means it can be effective in environments prone to spills. However, users may overlook the importance of load ratings. Choosing a grating with the correct specifications is crucial. Miscalculating can lead to safety hazards, especially in high-traffic areas.

In addition to safety concerns, maintenance is another aspect to consider. Despite its corrosion resistance, galvanized steel can still require periodic inspections. This helps to identify wear or potential failure points. The choice of galvanized steel grating is often influenced by these factors. Ensuring proper weight distribution and selecting the correct type can greatly affect its lifespan and performance.

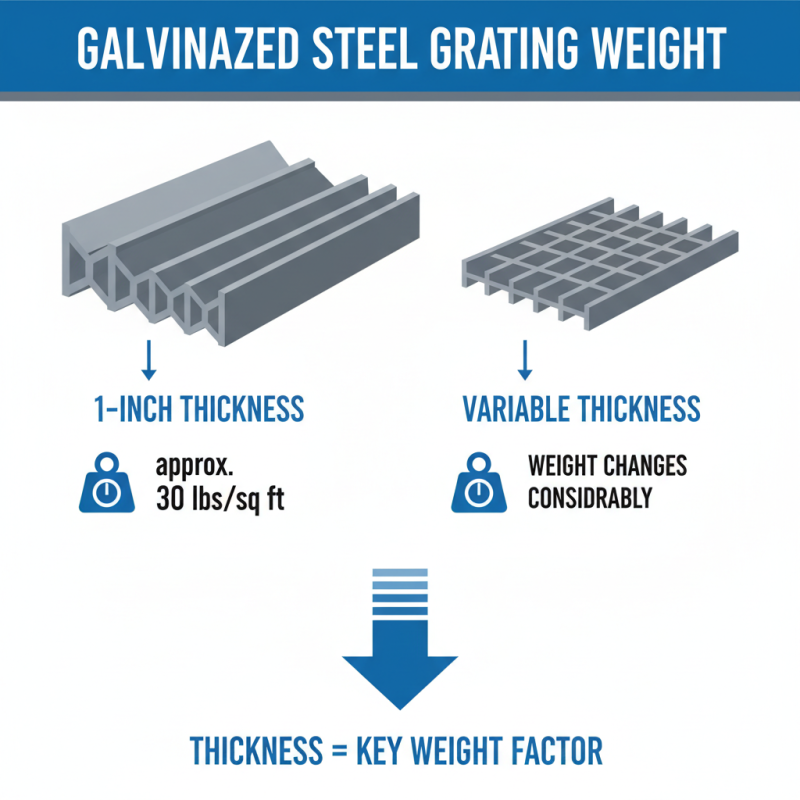

When considering galvanized steel grating, weight is an important factor. Several variables influence this aspect. Firstly, the grating's thickness significantly affects its overall weight. For example, a 1-inch thick grating can weigh approximately 30 pounds per square foot. Thickness variations will lead to considerable weight differences.

Another factor is the spacing of the bars. Closer spaced bars provide greater support, but also add weight. A common spacing is 1.5 inches, but options range from 1 inch to 3 inches. This choice impacts not just the weight but also the structural integrity. Grating designed for heavy loads may weigh more due to these factors.

The type of steel used will also influence weight. Different steel grades have varying weights. Grades such as ASTM A36 are heavier than high-strength variants, which can reduce weight without compromising strength. The added galvanization process, while protective, can slightly increase weight as well. Understanding these details can aid in making informed choices, especially when planning installations.

Calculating the weight of galvanized steel grating involves understanding several key factors. The size and thickness play crucial roles. Commonly used thicknesses range from 1/4 inch to 1 inch. Each increase in thickness significantly adds to the weight.

The material density also impacts calculations. Galvanized steel has a density of around 490 pounds per cubic foot. It's important to measure the length and width accurately. For example, a grating panel with dimensions of 2 feet by 4 feet will weigh differently than a 3-foot by 6-foot panel. The formula for calculation remains straightforward: multiply volume by density.

When weighing options, consider installation ease versus material heft. Heavier gratings offer more strength but can be cumbersome. Lighter options are easier to handle and install. However, they may not provide the same durability. Reflecting on these trade-offs is essential for choosing the right grating for your needs.

This chart represents the average weight of different sizes of galvanized steel grating units based on their dimensions (length x width x height) and typical weight per square meter.

When comparing different steel grating types, weight is a critical factor. Galvanized steel grating typically weighs between 4 to 10 pounds per square foot, depending on its thickness. The material composition plays a significant role in this variation. For example, heavier-duty options like welded grating can weigh significantly more than lighter types like molded grating.

A study by the Steel Industry Association found that the weight of steel grating can influence load-bearing capacities and installation requirements. Galvanized steel is known for its corrosion resistance, but it also adds weight compared to painted or untreated options. This resistance to corrosion often justifies the extra weight in many industrial applications.

Interestingly, while weight is important, some project managers overlook this aspect. They often prioritize cost or aesthetics over functionality. However, understanding the weight differences among grating types can lead to better material choices. Selecting the right type of steel grating involves considering both weight and the specific demands of the installation site. Not all projects benefit from heavier materials, and this can lead to overengineering in some cases. Every grating type carries strengths and weaknesses. It's essential to evaluate these aspects carefully.

Galvanized steel grating is widely utilized in various industries. Its versatility makes it suitable for platforms, walkways, and ventilation grills. This type of grating is known for its strength and durability. It withstands heavy loads while providing excellent drainage.

The load-bearing capacity of galvanized steel grating depends on its thickness and span. Thicker grating can support more weight. Spaces between the bars allow for easy flow of liquids and debris. This feature is particularly beneficial in industrial settings. It minimizes the risk of slipping and enhances safety on work sites.

Certain functions of galvanized steel grating may not match expectations. For instance, under extreme weather or heavy impact, some grating may warp. Inspecting it regularly can prevent safety hazards. Choosing the right type for specific needs is essential. Factors like load requirements and environmental conditions should guide decisions. Making informed choices will maximize the benefits of using galvanized steel grating.