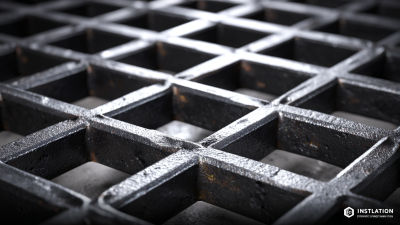

When it comes to construction and industrial applications, understanding the weight of black steel grating is crucial for ensuring structural integrity and safety. Black steel grating weight not only impacts the choice of materials during the design phase but also affects transportation, installation, and overall performance of the grating in various environments.

In this guide, we will delve into the key factors that influence the weight of black steel grating, including dimensions, material properties, and load-bearing capabilities.

Moreover, accurate calculations are essential when estimating black steel grating weight, as they help in making informed decisions that align with project specifications. We will explore various calculation methods and considerations that can assist engineers and contractors in selecting the right type and amount of steel grating for their specific needs.

By comprehensively understanding these aspects, stakeholders can optimize their resources and enhance operational efficiency in their projects. Join us as we uncover the intricacies of black steel grating weight and its pivotal role in successful construction outcomes.

The weight of black steel grating is influenced by several key factors that are vital for understanding its application and performance in various industries. Firstly, the thickness of the steel bars plays a significant role; thicker bars not only increase the weight but also enhance the load-bearing capacity of the grating. Additionally, the spacing between the bars, commonly referred to as the bear spacing, affects the total weight. Tighter spacing generally means more bars per unit area, leading to an increase in overall weight.

Another important factor is the type of steel used in manufacturing the grating. Standard black steel has a different weight compared to treated or coated variations, as the coatings can add extra mass. Furthermore, the design of the grating itself is a consideration; specific patterns and configurations can either increase or decrease the weight, depending on the intended use. Understanding these factors is paramount for engineers and builders who must select the appropriate grating for their projects while managing weight specifications efficiently.

When it comes to calculating the weight of black steel grating, several key factors play a vital role.

Primarily, the gauge of the steel and the dimensions of the grating—such as load-bearing capacity and spacing—are crucial elements in determining overall weight.

According to industry data, standard black steel grating typically weighs between 100 to 300 pounds per square foot, depending on these variables. The thickness of the steel bars can significantly influence weight;

for example, grating with a thickness of 1 inch can weigh up to 50% more than grating with a thickness of 3/4 inch.

To accurately calculate the weight of steel grating, one can use a simple formula: Weight = Area × Weight per square foot.

This straightforward calculation can help engineers and designers ensure they are selecting the appropriate grating for their projects.

Tips:

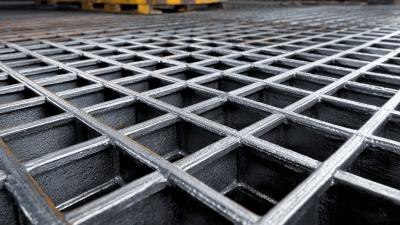

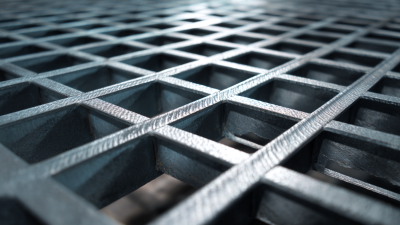

When selecting a type of steel grating, it’s essential to understand the comparative properties and advantages of different materials. Black steel grating, commonly fabricated from carbon steel, is known for its strength and durability, making it ideal for heavy-duty applications. Its weight can vary significantly based on the type of grating—be it welded, pressed, or swaged. Each manufacturing technique affects the overall load-bearing capacity and the weight per square foot, influencing both installation processes and structural support needs.

In contrast, stainless steel grating offers enhanced corrosion resistance, making it preferable for environments exposed to moisture or chemicals. This type tends to be lighter in weight compared to black steel grating, yet still maintains high strength. Moreover, aluminum grating presents an even lighter alternative, suitable for lightweight applications while providing decent load support. A comprehensive analysis of these materials reveals critical considerations such as cost, maintenance, and longevity, which ultimately guide the choice of steel grating for specific projects. Understanding these differences is crucial for optimizing both the performance and efficiency of your installation.

Black steel grating is widely used across various industries due to its robust load-bearing capabilities and versatility. Its applications range from walkways and platforms to industrial flooring and drainage covers. According to industry reports, black steel grating can support loads of up to 1,200 pounds per square foot, making it a reliable choice for heavy-duty operations. Compared to alternative materials, black steel grating's strength-to-weight ratio provides significant advantages in terms of structural integrity and safety.

In light of safety considerations, especially in mining environments, the decision to choose materials like fibreglass grating is gaining traction. Fibreglass offers a lightweight yet durable alternative while significantly reducing the risk of slip and fall accidents. Recent trends show that fibreglass products can enhance safety features by preventing corrosion, a crucial factor in harsh working conditions.

Tips for selecting the appropriate grating include considering the environment and load requirements. For instance, in areas exposed to chemicals or extreme weather, fibreglass may be preferable due to its corrosion resistance. Additionally, ensure the chosen material meets relevant safety standards and load capacities for specific applications to maximize efficiency and safety on site.

When it comes to maintaining black steel grating, understanding its susceptibility to corrosion and wear is essential for extending its lifespan. According to the National Association of Steel Manufacturers, nearly 60% of steel products are affected by rust, especially in environments exposed to moisture. To safeguard against this, regular inspections and prompt replacement of any damaged sections are critical. A preventative maintenance schedule should prioritize cleaning the grating surfaces and ensuring drainage pathways remain unobstructed, which helps reduce water collection and minimizes corrosion risks.

Moreover, applying protective coatings, such as galvanized finishes or powder coatings, can significantly enhance the durability of steel grating. A study by the American Galvanizers Association shows that hot-dip galvanization can provide up to 70 years of corrosion protection in certain environments. Additionally, employing techniques like sandblasting before coating can further improve adhesion and effectiveness. By investing time and resources into these maintenance practices, facility managers can ensure that steel grating continues to serve its crucial role in structural integrity and safety over the long term.