Steel Bar Grating has emerged as an essential solution in various industrial and commercial applications, owing to its durability, versatility, and cost-effectiveness. According to a recent market research report by Grand View Research, the global bar grating market is projected to reach USD 1.3 billion by 2025, growing at a compound annual growth rate (CAGR) of 4.8%. This upward trend highlights the increasing adoption of Steel Bar Grating in sectors such as construction, energy, and manufacturing, where safety and accessibility are paramount. The inherent benefits of steel, including its strength-to-weight ratio and resistance to environmental stressors, make Steel Bar Grating an optimal choice for walkways, drainage covers, and platform flooring, thereby enhancing operational efficiency and safety. As industries continue to evolve, understanding the expansive applications and advantages of Steel Bar Grating becomes crucial for maximizing its potential in various settings.

Steel bar grating is a highly versatile material used across various industries, primarily due to its strength and accessibility. There are several types of steel bar grating, including welded, swaged, and press-locked grating. Welded grating, known for its durability, is created by welding crossbars to bearing bars, providing a robust structure ideal for heavy-duty applications. Swaged grating, on the other hand, utilizes a process where the crossbars are mechanically connected to the bearing bars, yielding a lightweight yet strong product, perfect for applications requiring easy handling.

When considering specifications, one of the key factors is the spacing between the bars, which can influence load-bearing capacity and drainage efficiency. Typical spacing ranges from 1 inch to 2 inches, depending on specific project needs. Additionally, steel bar grating can vary in thickness—typically ranging from 1 inch to 1.5 inches—with thicker bars providing enhanced strength. Coatings such as galvanized or powder-coated finishes also significantly impact corrosion resistance, prolonging the lifespan of the grating in challenging environments. Overall, understanding the different types and specifications of steel bar grating is crucial for selecting the right solution for your project needs.

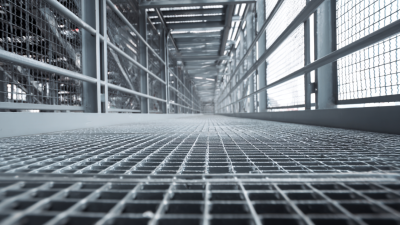

Steel bar grating is an essential material widely utilized in various industrial settings due to its strength, durability, and versatility. One of the primary applications is in flooring and walkways, where it provides a safe, slip-resistant surface that allows for efficient drainage of liquids, reducing the risk of accidents. Industries such as manufacturing and warehousing benefit from the lightweight yet robust design of steel bar grating, which can support heavy loads while facilitating movement and access throughout facilities.

In addition to flooring, steel bar grating is frequently employed for platforms, stair treads, and safety guards. Its open design ensures maximum air circulation and light penetration, making it an ideal choice for environments that require both visibility and safety. In chemical plants or food processing facilities, where spills can occur, the grating allows for easy cleanup and maintenance. Moreover, the customizable nature of steel bar grating means it can be tailored to meet specific safety and structural needs, making it a valuable asset in any industrial operation.

Steel bar grating has become an essential element in modern construction and design due to its remarkable versatility and myriad benefits. One of the key advantages of using steel bar grating is its strength and durability, making it ideal for applications ranging from flooring to walkways. Its lightweight nature allows for easy installation while maintaining structural integrity, which is particularly beneficial in construction projects requiring reliable support without excessive weight.

Tips: When selecting steel bar grating for your project, consider the load capacity and bar spacing to ensure it meets safety standards and functional requirements. Additionally, opting for corrosion-resistant coatings can enhance the longevity of the grating in outdoor environments where exposure to the elements is a concern.

Another noteworthy benefit is the ease of maintenance associated with steel bar grating. Unlike traditional materials that may deteriorate over time, steel grating can be easily cleaned and inspected, enabling long-term savings in maintenance costs. Furthermore, its open design allows for excellent drainage, reducing puddling and slip hazards in areas prone to moisture accumulation.

Tips: Regularly inspect your steel bar grating installations to identify any wear or damage early. Implementing a routine maintenance schedule can prevent long-term issues and ensure the longevity of your construction elements.

When it comes to installing steel bar grating, following best practices can significantly enhance the efficiency and durability of your installation. First, it is essential to prepare the substrate adequately; ensuring that the surface is clean and free from debris will promote better adhesion and stability. It's recommended to use a level to assess the evenness of the installation area, adjusting as necessary to avoid complications post-installation.

Next, selecting the right tools and safety gear is crucial. Heavy-duty gloves and eye protection should be worn to prevent injuries during handling and cutting. When positioning the grates, always allow for slight gaps for expansion and contraction, especially in areas subject to fluctuating temperatures. Utilizing proper fastening methods—whether welding, bolting, or using clips—will ensure that the grating remains securely in place. Additionally, regularly inspect the installation for wear and tear to address any issues proactively, maintaining the integrity and safety of the structure.

Maintenance and safety are critical considerations when utilizing steel bar grating systems in various applications. Regular inspections are essential to ensure that the grating remains structurally sound and free from corrosion. Accumulation of debris or contaminants can compromise the surface, leading to potential slips or falls. Implementing a scheduled cleaning routine, along with visual checks for signs of wear, helps to maintain both safety levels and the longevity of the grating.

In addition to maintenance, safety features such as proper installation and the use of anti-slip coatings can significantly enhance the effectiveness of steel bar grating systems. It is important to adhere to manufacturer guidelines and industry standards during installation to ensure that the grating performs optimally under load conditions. Furthermore, providing adequate signage and training for personnel using areas with steel bar grating can promote awareness and adherence to safety practices, reducing the likelihood of accidents in environments where these systems are deployed.