In the realm of industrial applications, Mill Finish Steel Grating stands out as a pivotal element, celebrated for its unique properties and functionalities. According to a recent industry report by Grand View Research, the global steel grating market is projected to reach USD 1.2 billion by 2025, driven largely by the growing demand for durable, cost-effective solutions in sectors such as construction, manufacturing, and transportation. Mill Finish Steel Grating, characterized by its uncoated finish and resistance to corrosion, provides advantages that are critical in various environments—particularly in heavy-duty applications where strength and safety are paramount. This blog will explore the distinctive features of Mill Finish Steel Grating, offering valuable tips on its selection and application to optimize performance and longevity in industrial settings.

Mill finish steel grating is becoming increasingly prominent in industrial applications due to its unique characteristics that cater to the needs of energy-intensive environments. One of the main attributes of mill finish steel grating is its exceptional strength-to-weight ratio. This allows for effective load support in facilities where heavy machinery operates, thereby enhancing safety without compromising efficiency. According to recent studies, structures employing upgraded materials, such as mill finish steel, have demonstrated up to 20% higher structural integrity compared to conventional options.

Additionally, mill finish steel grating exhibits outstanding resistance to environmental stressors, including corrosion and wear. This trait is crucial in industrial settings where exposure to moisture and chemicals is common. Research shows that using such materials can reduce maintenance costs significantly, with some reports indicating savings of up to 15% over a lifecycle due to lower replacement and repair needs. Furthermore, in the context of evolving energy efficiency optimization strategies, integrating mill finish steel grating aligns well with modern demands for sustainability and resource management. These characteristics make it a formidable choice for industries looking to enhance operational performance while remaining eco-conscious.

| Characteristic | Description | Benefits |

|---|---|---|

| Corrosion Resistance | Mill finish steel grating has a protective coating that resists oxidation and rust. | Increases longevity and reduces maintenance costs. |

| Load Bearing Capacity | Designed to withstand heavy loads and impacts. | Ideal for industrial and commercial applications that require durability. |

| Slip Resistance | The surface texture provides traction underfoot. | Enhances safety in workplaces, especially in wet or oily conditions. |

| Lightweight Design | Constructed to be lighter than traditional steel grating. | Easier to handle and install, reducing labor costs. |

| Cost-Effectiveness | Offers a balance of quality and price in industrial applications. | Reduces overall project costs while maintaining structural integrity. |

| Versatility | Can be used in various settings, including flooring, walkways, and platforms. | Adaptable to different industrial environments and requirements. |

Mill finish steel grating is rapidly becoming a preferred choice in various industrial applications due to its unique benefits related to safety and durability. Unlike painted or coated grating, mill finish steel grating showcases an unrefined surface that provides excellent slip resistance, making it ideal for high-traffic areas. According to industry reports from the American Institute of Steel Construction, mill finish surfaces have demonstrated a reduction in slip accidents by up to 25% compared to coated options, significantly enhancing workplace safety.

In addition to safety, the durability of mill finish steel grating is remarkable. Its inherent resistance to corrosion is attributed to the natural protective layer that forms on the steel’s surface. An analysis by the National Association of Corrosion Engineers reported that mill finish steel can withstand harsh environments and extreme temperatures, extending its lifespan by 30% when compared to other types of grating. This makes it a cost-effective solution for businesses looking to minimize maintenance costs and downtime.

Tip: When selecting mill finish steel grating, consider the environment where it will be installed. Ensuring proper drainage and regular cleaning can further enhance its durability and slip-resistance properties, maximizing the benefits of this robust material.

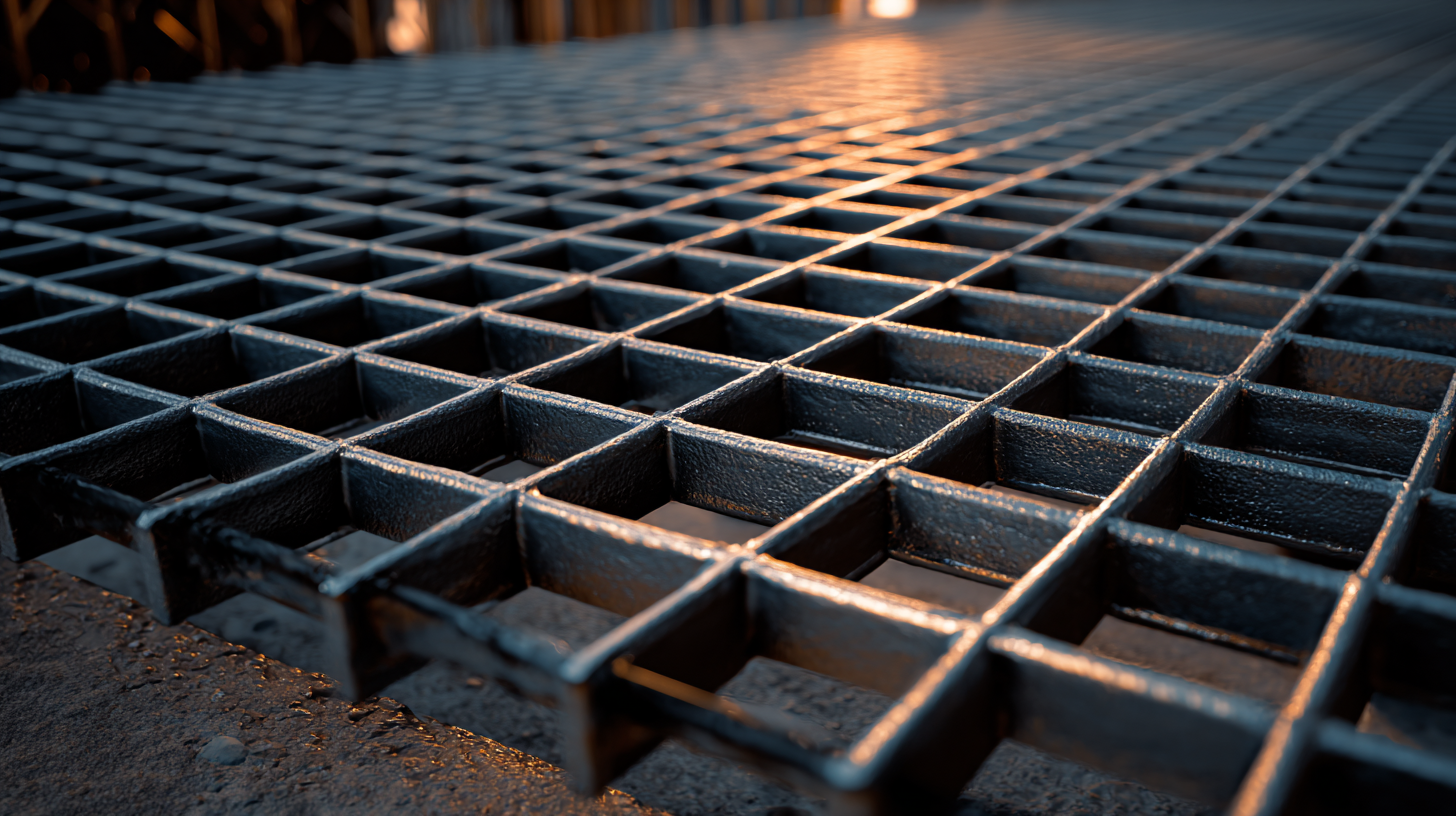

Mill finish steel grating stands out in industrial applications due to its unique properties and versatility. Commonly used in sectors such as manufacturing, construction, and transportation, this type of grating is valued for its strength and resistance to wear. According to a report by the Global Steel Grating Market, the demand for industrial steel grating is expected to grow at a CAGR of 5.8% from 2021 to 2028, reflecting the increasing reliance on durable materials in infrastructure projects.

In the manufacturing sector, mill finish steel grating is extensively utilized for flooring, walkways, and platforms, providing a reliable solution for heavy equipment and foot traffic. Its anti-slip surface is particularly important in environments where safety is paramount. Additionally, in the construction industry, mill finish steel gratings are often employed in drainage systems to ensure water management efficiency. The Automotive Industry Association has noted a growing trend toward using steel grating for better vehicle assembly lines, projecting a rise in demand due to the push for more automated and efficient manufacturing processes. These applications highlight the integral role of mill finish steel grating in enhancing operational efficiency across various industries.

Mill finish steel grating is widely recognized for its durability and strength, making it a preferred choice in various industrial applications. However, to maximize its lifespan and maintain its functionality, proper maintenance is essential. Regularly scheduled inspections can help identify any signs of wear or corrosion, allowing for timely interventions that can prevent more significant damage.

One effective tip for maintaining mill finish steel grating is to keep the surface clean and free from debris. Regular washing with water and mild detergents will help remove any buildup of dirt, oils, or chemicals that may accelerate corrosion. Additionally, consider applying a protective coating periodically to shield the metal from environmental factors.

Another important maintenance tip is to address rust spots immediately. Small areas of corrosion should be sanded down and treated with rust-inhibiting primer and paint. This not only maintains the aesthetic appeal of the grating but also reinforces its structural integrity, ensuring it continues to perform effectively in demanding settings.

Mill finish steel grating has become a popular choice in various industrial applications due to its unique characteristics and benefits. When compared to other grating types, such as painted or galvanized options, mill finish steel grating stands out for its inherent durability and resistance to corrosion. This raw, uncoated finish allows for easy fabrication and customizations to suit specific project requirements, making it a versatile option for construction and structural engineering. Moreover, the ability to maintain a strong grip underfoot, even in harsh environments, enhances its safety features.

In contrast, painted or galvanized gratings may provide a layer of protection initially, but they can deteriorate over time due to wear and environmental exposure. Recent analyses have referenced significant performance discrepancies in applications where shear failure occurred, highlighting the importance of material selection. For instance, when comparing the performance of various materials used in bridge construction, the resilience of mill finish steel grating in supporting heavy loads becomes evident. This effectiveness is further demonstrated through innovative technologies like long gauge length bragg grating sensors, which enhance the structural monitoring of installations. Ultimately, the choice of mill finish steel grating addresses both safety and efficiency needs in industrial settings.

This bar chart illustrates the comparative load capacity of four different types of grating commonly used in industrial applications. Mill Finish Steel Grating offers a competitive option while maintaining specific advantages in various contexts.