The importance of Low Carbon Steel Grating in industrial applications is becoming increasingly recognized, particularly as industries strive to meet sustainability targets and reduce their carbon footprints. According to the Global Market Insights report, the demand for low carbon steel products is projected to grow at a CAGR of over 5% from 2021 to 2027, driven by the need for durable and cost-effective materials in construction, manufacturing, and energy sectors. Low Carbon Steel Grating, known for its strength, lightweight properties, and resistance to corrosion, serves a critical role in various applications ranging from walkways and platforms to drainage systems. As industries face challenges such as rising material costs and environmental regulations, the unique applications of Low Carbon Steel Grating provide innovative solutions that enhance operational efficiency while addressing sustainability concerns. This blog will explore these unique applications and the associated benefits across different industries, highlighting the strategic advantages of incorporating Low Carbon Steel Grating into operational frameworks.

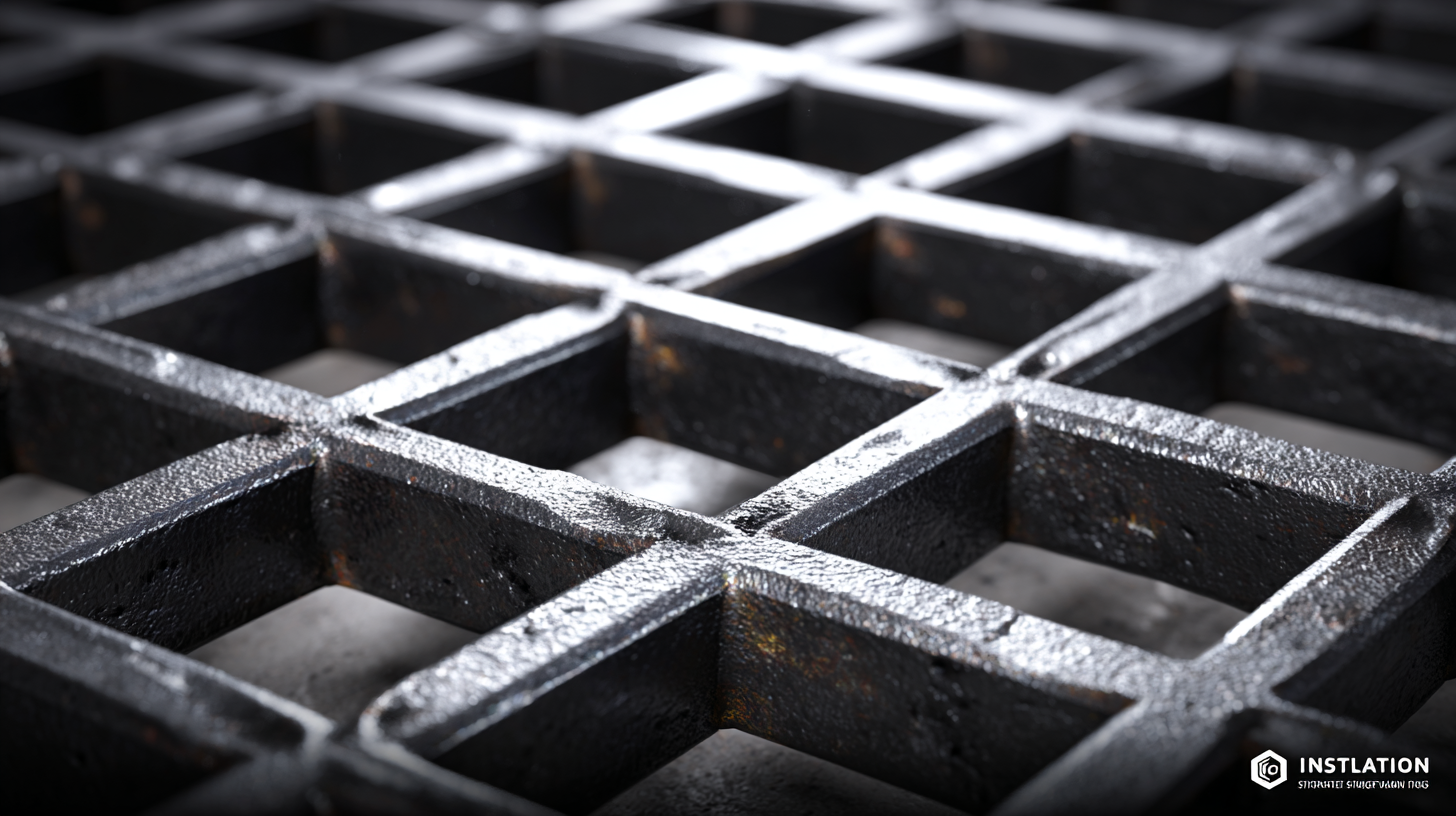

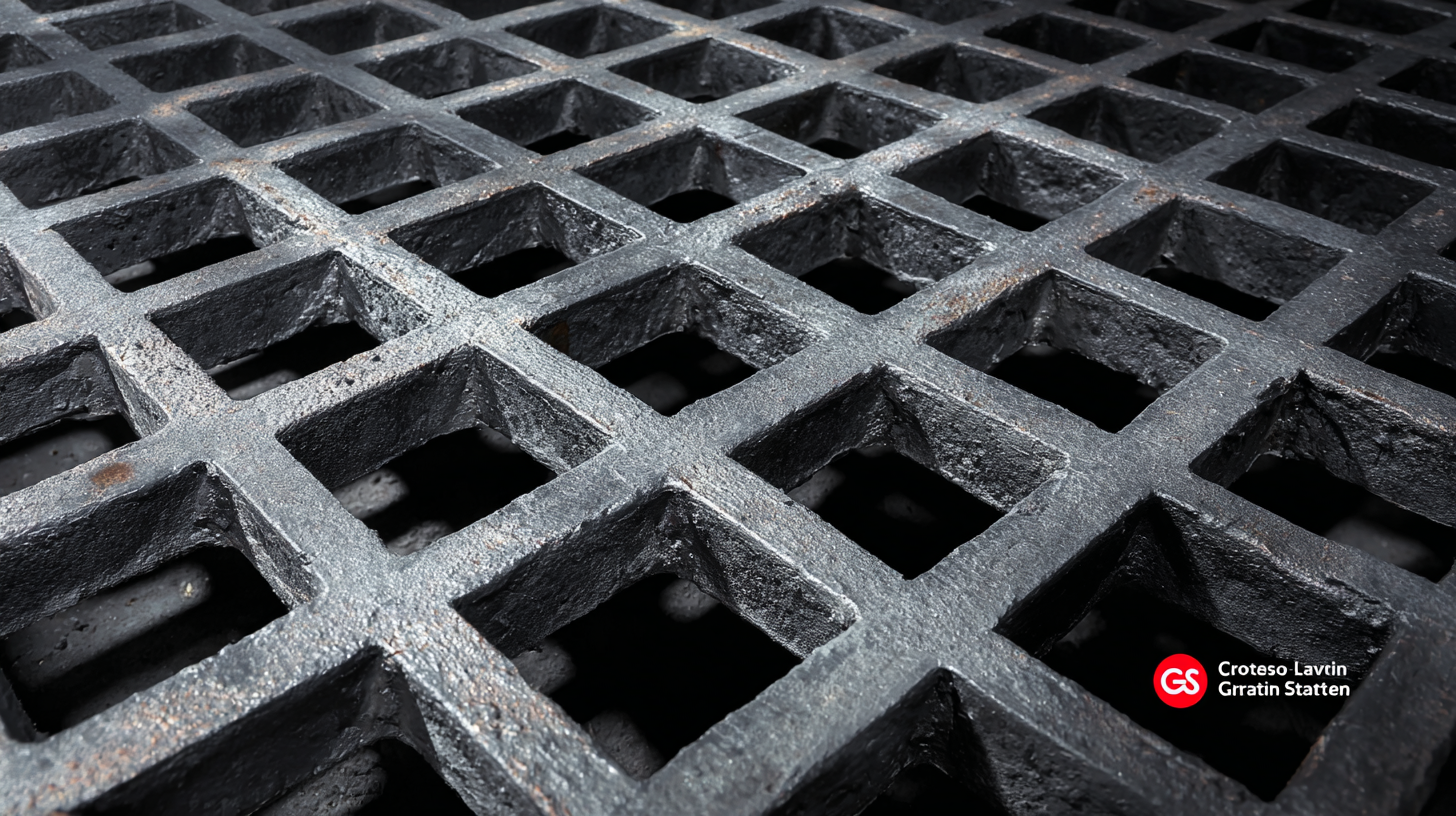

Low carbon steel grating has emerged as a game changer in various construction projects due to its remarkable weight reduction capabilities. With a weight reduction benefit of up to 25%, structures can be significantly lighter without compromising on strength or durability. This characteristic not only facilitates easier handling and installation but also reduces the load on supporting structures, enhancing overall stability and longevity.

Moreover, the application of low carbon steel grating extends beyond mere weight savings. Its corrosion resistance and cost-effectiveness make it an ideal choice for both indoor and outdoor settings, from commercial buildings to industrial facilities. The design flexibility offered by low carbon steel grating allows for creative solutions tailored to specific project requirements, proving that functionality and aesthetics can go hand in hand. As industries increasingly seek sustainable and efficient materials, low carbon steel grating stands out as a versatile component in modern construction practices.

Low carbon steel grating has emerged as a crucial element in enhancing safety across various industries, particularly due to its significant improvement in slip resistance. Recent studies indicate that low carbon steel grating can provide up to 30% increased slip resistance compared to traditional materials, making it an ideal choice for high-traffic areas. This enhancement is critical in environments prone to wet or slippery conditions, such as in the food processing, petrochemical, and construction industries, where maintaining safety standards is paramount.

The American National Standards Institute (ANSI) outlines the importance of slip resistance in workplace safety, stating that approximately 20% of all workplace injuries are caused by slips and falls. The unique design of low carbon steel grating, with its superior load-bearing capabilities and profile structure, allows for better drainage and reduces the likelihood of slipping. In fact, the National Floor Safety Institute (NFSI) supports using materials that can provide enhanced traction, recommending low carbon steel grating for applications ranging from walkways to industrial platforms. Thus, the adoption of low carbon steel grating not only meets regulatory compliance but also significantly contributes to the overall safety and efficiency of operations in various sectors.

| Industry | Application | Slip Resistance Increase (%) | Benefits |

|---|---|---|---|

| Construction | Walkways and Platforms | 30% | Enhanced worker safety, compliant with safety regulations |

| Manufacturing | Machine Access Areas | 30% | Reduced accident risks, increased productivity |

| Transportation | Railway Walkways | 30% | Improved safety for maintenance crews |

| Oil and Gas | Offshore Platforms | 30% | Minimized slip hazards in harsh environments |

| Food and Beverage | Processing Areas | 30% | Ensures safe handling and compliance with hygiene standards |

Low carbon steel grating has emerged as a cost-effective solution for various industries, providing manufacturers with significant savings without compromising on quality. According to a recent industry report by the Metal Grating Association, utilizing low carbon steel for grating can result in up to a 15% reduction in material costs compared to traditional materials like stainless steel or heavy-duty plastic options. This is particularly advantageous for manufacturers who are constantly seeking ways to optimize their expenses while maintaining the durability of their products.

Additionally, the flexibility and strength of low carbon steel make it suitable for diverse applications, from industrial flooring to drainage systems. The Shifting Steel report indicates that the demand for low carbon steel grating has increased by 25% over the past three years, driven largely by its cost-effectiveness and ease of installation. Manufacturers are recognizing that investing in low carbon steel grating not only lessens their upfront material costs but also minimizes long-term maintenance expenses due to its robust nature, which results in lower lifecycle costs overall.

The drive for sustainability has become a pivotal factor in industrial choices, and best low carbon steel grating stands out as an exemplary solution. With a remarkable 40% lower carbon footprint compared to traditional steel options, this innovative material not only reduces environmental impact but also aligns with the increasing demand for eco-friendly building practices. Manufacturers and industries are now prioritizing sustainability metrics in their material selection, and low carbon steel grating meets these criteria effectively.

In various applications—ranging from construction and infrastructure to manufacturing—using low carbon steel grating contributes significantly to lowering the overall carbon emissions. Its durability and sturdiness lend themselves well to high-traffic areas while maintaining lightness, which further promotes energy efficiency in transportation and installation. As businesses strive to meet regulatory standards and customer expectations around environmental responsibility, integrating low carbon steel grating into their operations becomes a strategic and sustainable choice that benefits both the planet and their bottom lines.

Low carbon steel grating has emerged as a versatile solution across various industries due to its strength, durability, and cost-effectiveness. One of the most notable applications is in the construction sector, where these gratings are used for flooring systems. According to the American Institute of Steel Construction, low carbon steel offers exceptional tensile strength while remaining lightweight, making it a preferred choice for commercial buildings' walkways and platforms. Additionally, its open design promotes water drainage, reducing the risk of slip hazards, which is crucial in high-traffic areas.

In the manufacturing and processing industries, low carbon steel grating serves as a crucial element for safety and operational efficiency. A report by IBISWorld highlights that increasing safety regulations have led to a growing demand for quality grating solutions in factories and warehouses. The use of low carbon steel grating not only enhances structural integrity but also provides an effective solution for both ventilation and containment in chemical plants. Moreover, the grating's resistance to corrosion can significantly lower maintenance costs, thus contributing positively to operational budgets. This makes it an ideal choice for enzyme and oil filtration systems, where typical wear and exposure to harsh environments are common.