In recent years, the demand for durable and efficient construction materials has led to the widespread use of Galvanized Steel Grating in various industrial applications. According to a report by Research and Markets, the global steel grating market is projected to reach approximately $3 billion by 2026, driven by the increasing emphasis on safety and efficiency in infrastructure development. Galvanized Steel Grating is favored for its corrosion resistance, high load capacity, and lightweight design, making it a go-to solution in sectors ranging from manufacturing to transportation.

However, as industries evolve, the search for unique alternatives that can offer similar benefits while catering to specific project needs has become imperative. In this blog, we will explore innovative alternatives to traditional Galvanized Steel Grating, examining their potential applications and advantages in modern engineering projects.

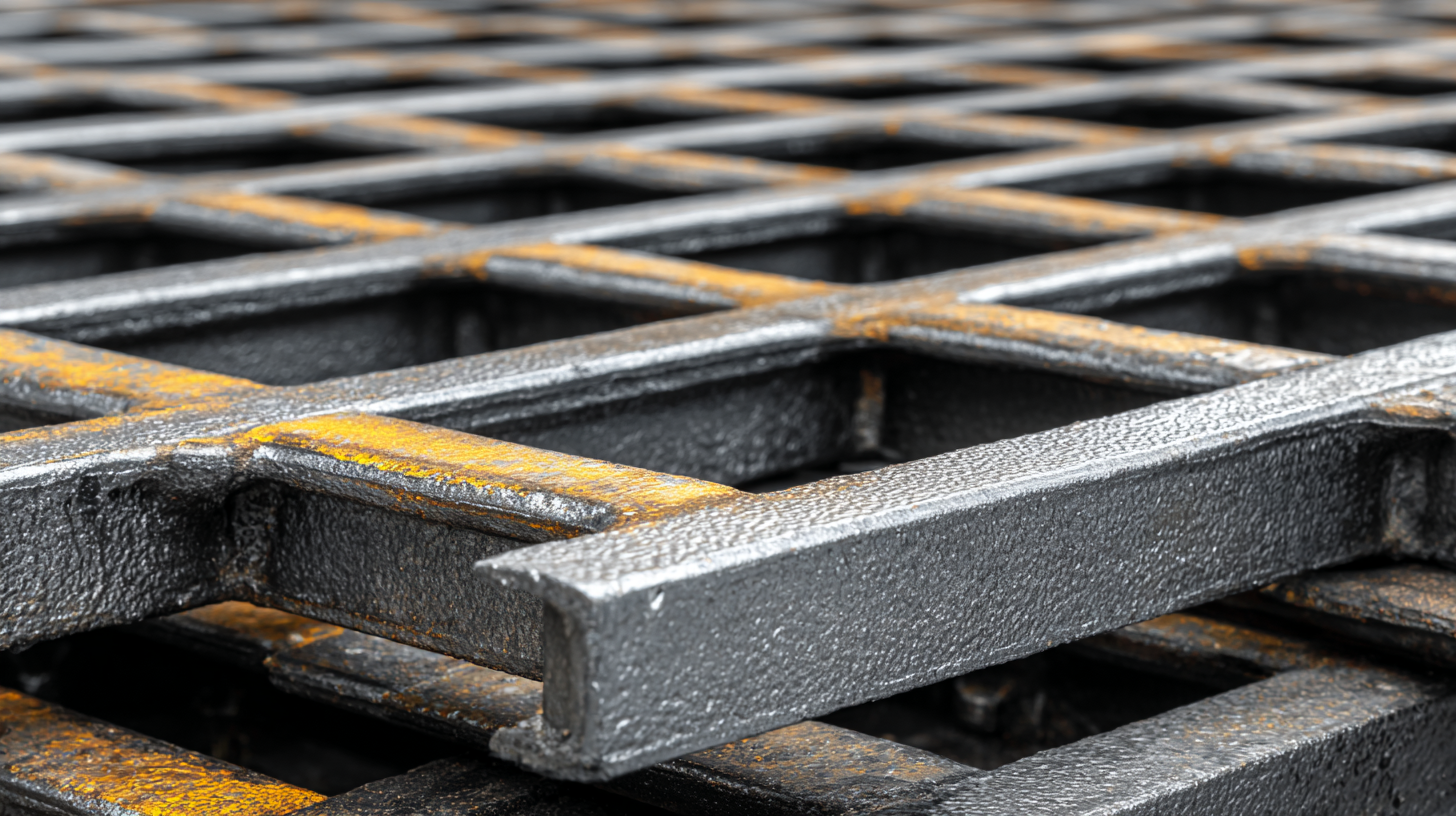

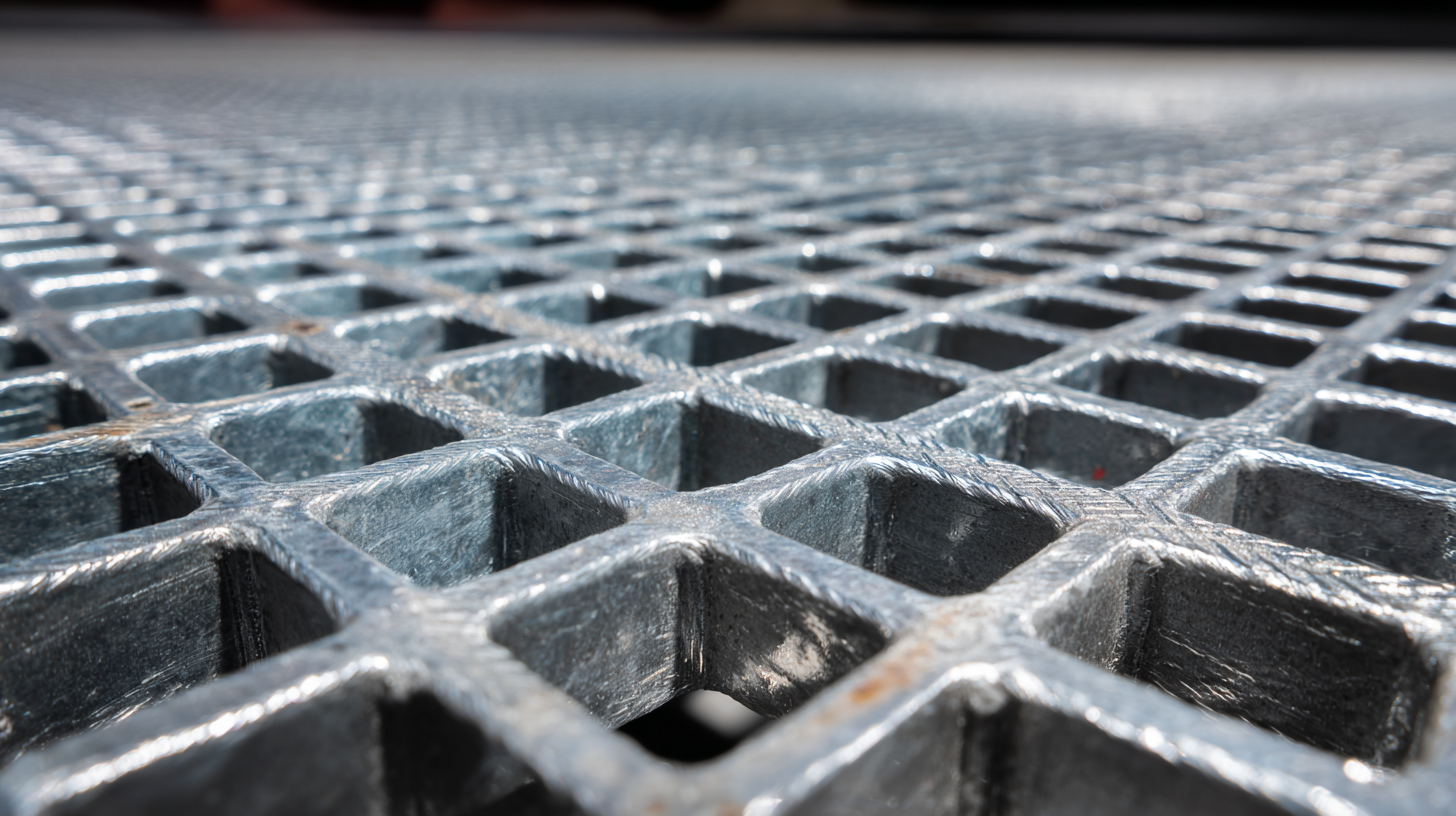

Galvanized steel grating has long been a staple in construction and manufacturing, offering durability and corrosion resistance. However, innovative applications of this material are transforming the landscapes of various industries. For example, in the automotive sector, galvanized steel grating is used in assembly lines to provide slip-resistant surfaces that enhance worker safety and productivity. Additionally, its lightweight yet sturdy design makes it an ideal choice for modular workstations, allowing for flexible configurations as production needs evolve.

Beyond traditional uses, the versatility of galvanized steel grating is finding new life in the renewable energy sector. Solar farms are increasingly utilizing this material for support structures and walkways, where its resistance to harsh environmental conditions ensures longevity and minimal maintenance. Furthermore, in wastewater treatment facilities, galvanized steel grating serves as a robust platform for advanced filtration systems, effectively supporting heavy machinery while facilitating easy access for inspection and maintenance. These innovative applications highlight the continuous evolution of galvanized steel grating, making it a key player in modern industrial solutions.

When considering materials for industrial projects,

galvanized steel grating has long been a popular choice due

to its durability and resistance to corrosion. However, various alternative materials can provide unique

benefits that cater to specific needs. For instance,

fiberglass grating stands out with its

lightweight nature and rust resistance, making it

ideal for environments where moisture is prevalent. Additionally, it can be manufactured in various colors

and styles, enhancing aesthetic appeal without sacrificing functionality.

Another alternative worth exploring is

aluminum grating, which, while slightly heavier than

fiberglass, offers excellent strength-to-weight ratios and high corrosion resistance. Its lightweight nature aids

in easy installation and transportation. Moreover, aluminum grating is non-magnetic and does not produce sparks,

making it particularly suitable for industries handling flammable materials. By comparing these alternatives

to galvanized steel grating, industries can make informed choices that align with their specific operational

requirements and environmental conditions.

When exploring alternatives to galvanized steel grating for various projects, understanding the specific load requirements and environmental conditions is crucial. Different grating materials can significantly impact performance, durability, and sustainability. For instance, fiberglass grating offers excellent corrosion resistance, making it a fitting choice for environments exposed to harsh chemicals or moisture. Alternatively, aluminum grating is lightweight yet strong, ideal for projects where weight is a concern, while still maintaining a robust structure to support needed loads.

Moreover, emphasizing environmental implications when selecting grating solutions can lead to both economic and ecological benefits. For example, using sustainable materials or designs that contribute to energy efficiency can align with modern project goals. A focus on incorporating innovative designs—such as those that improve air circulation for cooking stoves—can also enhance functionality while reducing carbon footprints. Taking these factors into account when selecting grating solutions will ensure you choose the best option tailored to your project's unique requirements.

When considering alternatives to galvanized steel grating, a comprehensive cost-benefit analysis is essential. According to a recent report from the Freedonia Group, the non-metal grating market is expected to grow by nearly 5% annually through 2025, indicating a significant shift towards cost-effective options such as fiberglass reinforced plastic (FRP) and aluminum. While galvanized steel is known for its durability, alternatives like FRP provide a lightweight solution that is resistant to corrosion and requires minimal maintenance, often leading to long-term savings.

Moreover, a study conducted by the Industrial Fasteners Institute reveals that while the upfront cost of alternative materials like composite grating can be higher—sometimes up to 25%—the total lifecycle cost can be considerably lower due to reduced replacement frequency and lower maintenance requirements. For instance, FRP can last up to three times longer than traditional galvanized steel in corrosive environments, thereby enhancing the overall value of an investment.

As project managers evaluate their options, understanding the trade-offs between initial costs and long-term benefits will be crucial in making informed decisions that align with both budget and operational needs.

When considering alternatives to galvanized steel grating for your projects, it's crucial to prioritize safety standards and compliance. The proper use of grating can significantly impact not only the functionality of your structure but also the safety of individuals interacting with it. Before selecting an alternative material, ensure it meets relevant safety guidelines and industry standards. This often includes load-bearing requirements, slip resistance, and corrosion resistance, which are essential for maintaining a secure environment.

Additionally, thorough testing and certification should be conducted to validate the alternative's performance under various conditions. Materials like fiberglass reinforced plastic (FRP) and aluminum may offer unique benefits, such as lightweight structures and increased resistance to specific environmental factors. However, each of these options comes with its own set of safety considerations that must be carefully evaluated. By complying with local regulations and industry best practices, you can confidently choose the right grating solution that upholds safety and ensures the success of your project.