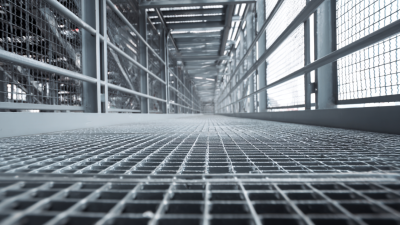

When it comes to industrial flooring and walkways, choosing the right Bar Steel Grating is essential for ensuring safety, durability, and efficiency. With an array of options available, understanding the various types of Bar Steel Grating and their applications can be daunting. From different materials and manufacturing processes to load capacities and surface types, the choices can significantly impact performance and maintenance requirements.

Whether you’re selecting grating for a heavy-duty industrial environment or a lighter application, having a comprehensive guide will empower you to make informed decisions that align with your specific needs. This ultimate guide aims to simplify the selection process by outlining key considerations, benefits, and potential drawbacks associated with different types of Bar Steel Grating, helping you find the perfect solution for your industrial requirements.

When it comes to selecting bar steel grating for industrial applications, understanding the various types available is crucial. Bar steel grating is typically categorized by its material, load-bearing capacity, and spacing. Common materials include carbon steel, stainless steel, and aluminum, each offering different benefits. For instance, stainless steel grating is highly resistant to corrosion and is ideal for environments exposed to chemicals or moisture. On the other hand, carbon steel, while less resistant to corrosion, is often more cost-effective and can bear heavier loads in dry conditions.

Another significant consideration is the load-bearing capacity and spacing of the grating bars. The spacing between bars can impact both the strength and functionality of the grating. Closer spacing provides more support and is ideal for areas with a high footfall or heavy machinery. Conversely, wider spacing may suit applications where drainage is a priority, as it allows for easier debris flow. Ultimately, understanding these different types and their specific characteristics ensures that you select the most suitable bar steel grating for your industrial needs, optimizing safety and performance.

This bar chart illustrates the weight per square meter of different types of bar steel grating materials commonly used in industrial applications. Understanding these parameters helps in selecting the most suitable grating for specific loading and environmental conditions.

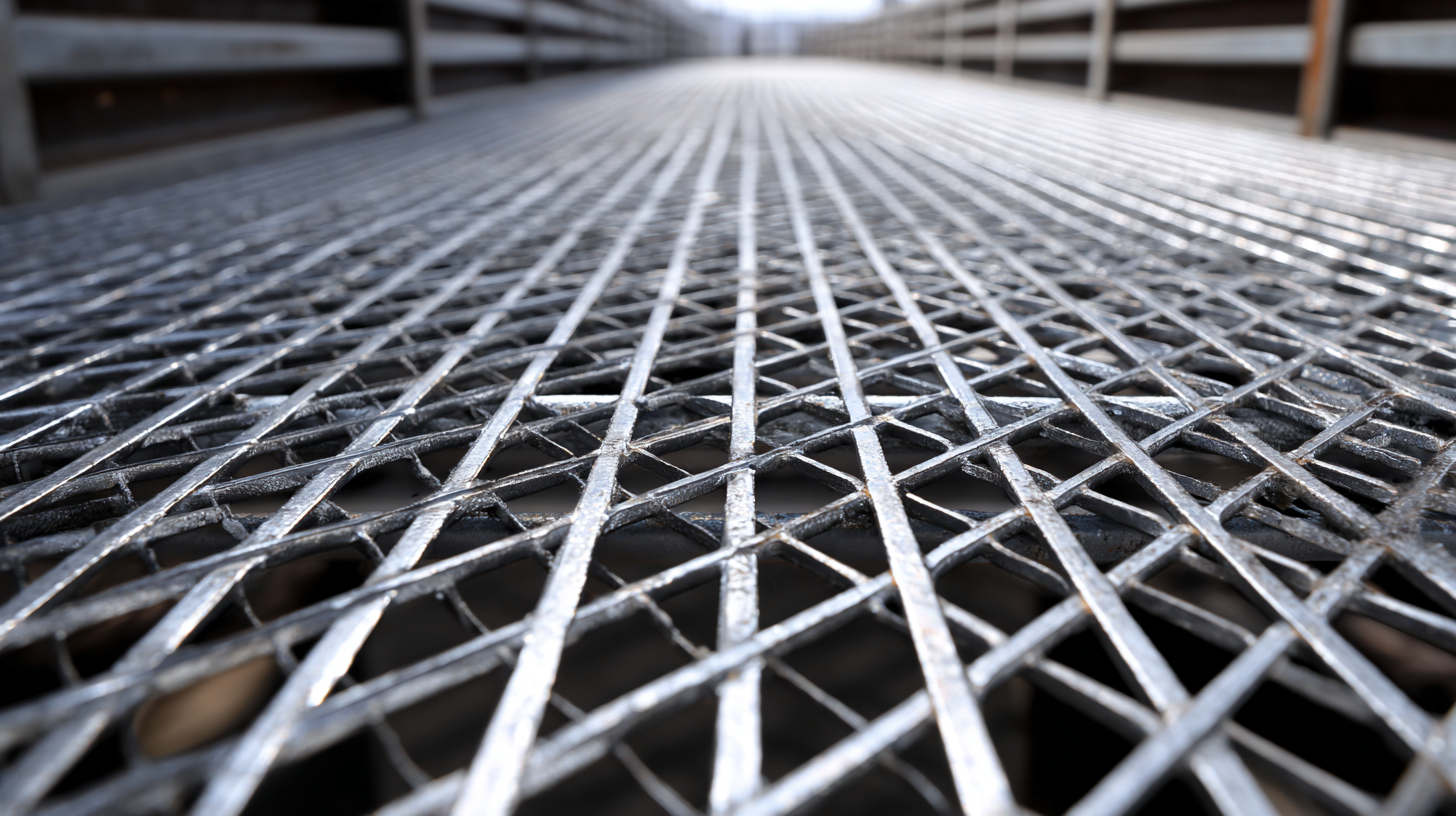

When selecting bar steel grating for industrial needs, several key factors must be considered to ensure optimal performance and safety. One critical aspect is the load-bearing capacity, which is defined by the grating’s material properties and the spacing between the bars. According to the Steel Grating Institute, steel grating typically exhibits superior strength, making it suitable for high-load environments such as manufacturing plants and heavy equipment areas.

Bar steel grating is an essential component in many industrial applications, delivering numerous advantages that make it a preferred choice over other flooring options. One of the top benefits is its exceptional load-bearing capacity. According to the American National Standards Institute (ANSI), properly designed bar grating can support loads of up to 1,200 pounds per square foot, making it ideal for high-traffic areas and heavy equipment use. This durability ensures maintenance costs are kept low over time, as fewer replacements and repairs are needed.

Another significant advantage is safety. The open design of bar steel grating allows for effective drainage and prevents the accumulation of water and debris, reducing slip hazards in industrial environments. A study by the National Safety Council indicates that slip and fall accidents in workplaces account for over 30% of all reported injuries. By using bar steel grating, facilities can mitigate these risks, ultimately leading to a safer work environment, which is invaluable for maintaining productivity and employee morale. Additionally, these gratings are customizable, allowing businesses to select sizes and spacing that best meet their specific operational needs, further enhancing their functionality and effectiveness.

When it comes to maintaining bar steel grating,

regular upkeep is essential to ensure its longevity and functionality. According to the

National Association of Architectural Metal Manufacturers,

proper maintenance can enhance the lifespan of steel grating by up to 50%. This involves routine inspections for signs of wear, corrosion, and loose components. Keeping grating surfaces clean and free from debris not only improves safety but also extends the material's life, as accumulated dirt can cause accelerated deterioration.

Additionally, applying protective coatings can significantly influence the durability of steel grating. A study from the

Steel Construction Institute suggests that galvanized coatings can improve corrosion resistance by over 30% in harsh industrial environments. Regularly re-evaluating the condition of these coatings, especially in areas exposed to chemicals or extreme weather, is vital. By following these essential maintenance tips, industries can not only save on replacement costs but also maintain a safe working environment for their employees.

When considering flooring options for industrial applications, cost is often a significant factor. Bar steel grating has long been a preferred choice due to its durability and strength. However, it’s essential to compare the costs associated with bar steel grating against alternative flooring solutions like concrete, rubber mats, or composite materials. While upfront costs for bar steel grating may be higher, its longevity and low maintenance requirements can lead to significant savings in the long run.

Tips: When evaluating the cost-effectiveness of your flooring options, include not just the initial purchase price, but also the installation, maintenance, and potential replacement costs over time. Conduct a life-cycle cost analysis to see how each option performs financially throughout its lifespan.

Additionally, consider the specific needs of your industrial environment. While bar steel grating may provide excellent drainage and ventilation, alternative flooring materials can offer benefits like enhanced slip resistance and noise reduction. Assessing these factors will help in making a comprehensive cost comparison that aligns with your operational requirements.

Tips: Always consult with suppliers to obtain quotes and inquire about any available warranties, as this can influence long-term value. Choosing the right material should also reflect the operational demands of your facility, ensuring performance meets your expectations.