In the construction and industrial sectors, the choice of materials significantly impacts the efficiency, safety, and sustainability of projects. One innovative solution gaining traction is Composite Steel Grating. According to a recent market analysis by Mordor Intelligence, the global market for composite materials, including grating systems, is projected to grow at a CAGR of 5.57% from 2021 to 2026. This growth is driven by the increased demand for lightweight yet durable alternatives in various applications, such as flooring, walkways, and platforms. Composite Steel Grating offers numerous advantages over traditional materials, including enhanced corrosion resistance, reduced weight, and ease of installation. As firms increasingly seek to improve operational efficiency while minimizing environmental impact, understanding the ultimate benefits of Composite Steel Grating becomes essential for making informed design choices in upcoming projects.

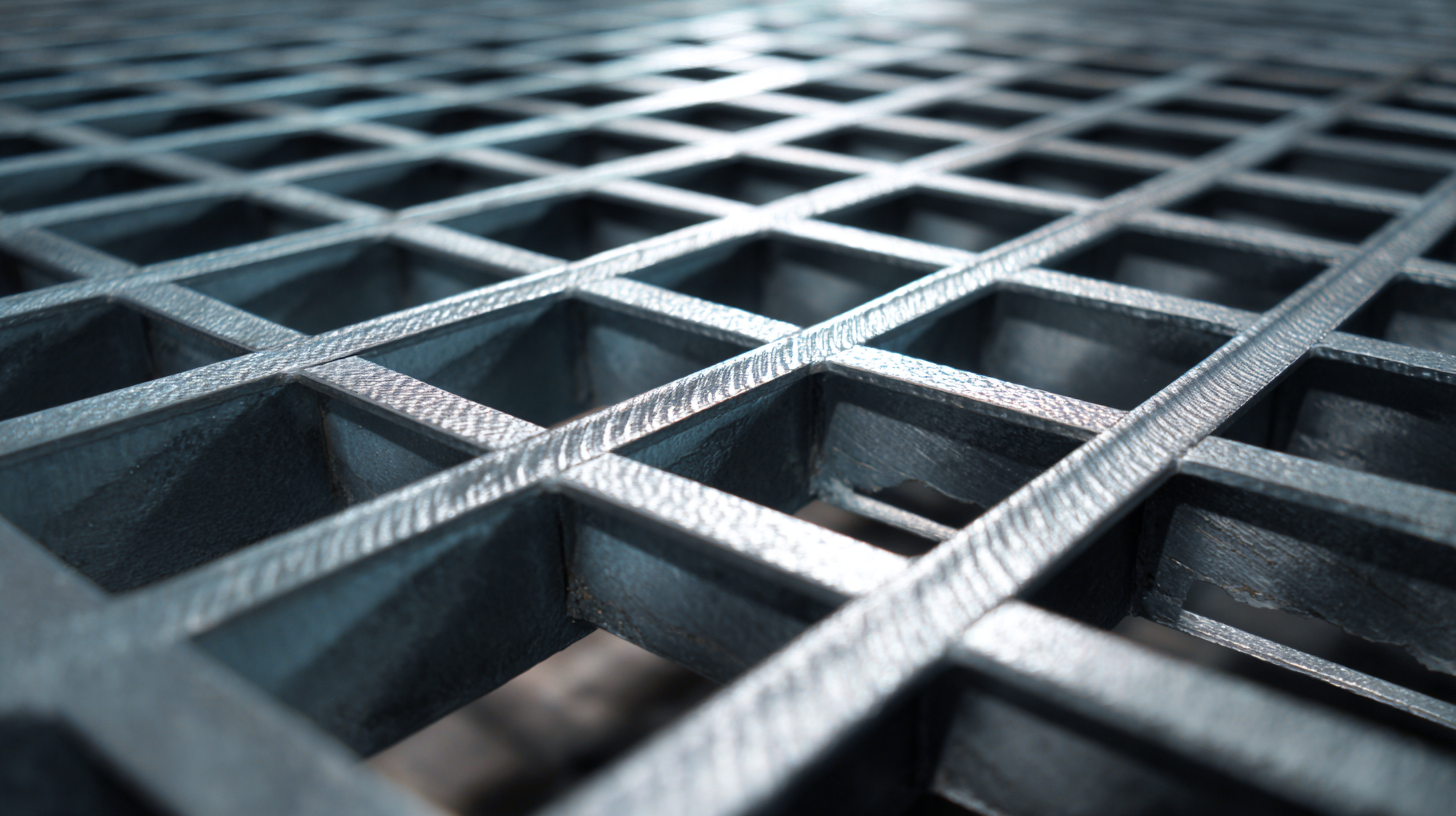

Composite steel grating has emerged as a superior alternative to traditional grating materials, offering a range of benefits that can greatly enhance project outcomes. One significant advantage of composite steel grating is its lower weight compared to conventional steel grating. According to a report by the American Composites Manufacturers Association (ACMA), composite materials can reduce structural load by as much as 30%, leading to lower installation costs and enhanced structural efficiency. This makes composite grating an ideal choice for applications where weight reduction is critical.

In terms of durability, composite steel grating resists corrosion and wear much more effectively than traditional materials. The National Association of Corrosion Engineers (NACE) reports that corrosion-related expenses in the U.S. alone exceed $276 billion annually. By opting for composite options, projects can significantly extend the lifespan of their installations and reduce maintenance costs.

Tip: For enhanced safety, consider integrating anti-slip coatings with composite steel grating—this adds another layer of protection, especially in high-traffic areas. Additionally, always cross-reference the specific load ratings of composite materials to ensure they meet the requirements of your project. Remember, selecting the right grating can have long-term benefits for both safety and cost-effectiveness.

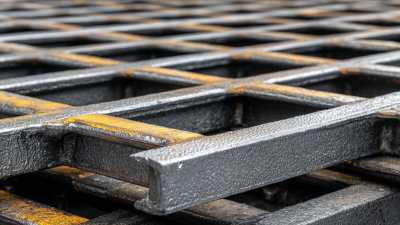

In industrial settings, safety is paramount, and composite steel grating stands out as a leading choice for enhancing safety features. One of the most significant advantages of composite steel grating is its slip-resistant surface. Designed for high-traffic areas, the textured surface helps minimize the risk of slips and falls, ensuring a secure environment for workers. This attribute is especially crucial in industrial facilities that deal with heavy machinery and frequent movement, where even minor accidents can lead to severe consequences.

Additionally, the lightweight nature of composite steel grating allows for easier handling and installation, reducing the risk of injury during setup. Unlike traditional materials, composite steel grating is engineered to withstand harsh conditions, which further contributes to its long-lasting performance. This durability is essential in industries frequently exposed to corrosive substances, as it maintains its structural integrity and safety features over time. As industries recognize the growing importance of workplace safety, incorporating composite steel grating into their projects presents an effective solution that meets both safety and operational efficiency requirements.

When considering cost-effectiveness for your next project, composite steel grating emerges as a superior choice. This innovative material not only boasts durability and longevity but also optimizes long-term savings that can significantly impact your project's bottom line. Utilizing composite steel grating can lead to substantial reductions in maintenance costs due to its resistance to corrosion and environmental wear, thus allowing for a longer lifespan compared to traditional materials. This means fewer replacements and less downtime, which translates to savings that accumulate over time.

Moreover, the initial investment in composite steel grating can be offset by the potential financial benefits it brings. With the rising costs associated with energy storage and efficiency improvements in various sectors, integrating composite solutions can reduce overall project expenditures. Studies suggest that substantial savings from energy-efficient technologies and effective material choices enable projects to yield better returns as opposed to those relying on conventional methods. By incorporating composite steel grating into your plans, you are not only enhancing the safety and functionality of your project but also making a financially sound decision that pays off in the future.

Composite steel grating has emerged as a versatile solution across a multitude of sectors, offering unique advantages that cater to specific industry needs. According to a recent industry report by Global Market Insights, the composite steel grating market is expected to reach USD 450 million by 2025, driven by increasing demand in the construction, oil and gas, and wastewater treatment industries. Its lightweight yet robust design makes it an ideal choice for various applications, from walkways and platforms to drainage covers.

In the construction industry, composite steel grating is favored for its ease of installation and maintenance, reducing labor costs by up to 25%, as reported by the American Institute of Steel Construction. The material's resistance to corrosion, particularly in harsh environments, ensures longevity and durability, making it suitable for facilities that require frequent cleaning and high hygiene standards, such as food processing plants. Furthermore, environmental sustainability is a significant aspect, with a reported 30% reduction in waste production during manufacturing compared to traditional grating solutions. This combination of performance and sustainability positions composite steel grating as a leading choice for innovative projects across various sectors.

| Benefit | Description | Applications | Industry |

|---|---|---|---|

| Durability | Resistant to harsh environmental conditions and chemicals. | Walkways, platforms | Manufacturing, Chemical Processing |

| Lightweight | Easy to handle and install, reducing labor costs. | Construction, maintenance access | Construction, Oil & Gas |

| Slip Resistance | Provides a safe walking surface in wet or oily conditions. | Industrial floors, stair treads | Mining, Maritime |

| Corrosion Resistance | Ideal for environments that promote rusting. | Outdoor walkways, chemical storage | Marine, Chemical Manufacturing |

| Versatility | Can be customized for various specifications and designs. | Bridges, architectural features | Construction, Architecture |

Choosing composite steel grating for your next project offers significant sustainability and environmental benefits that make it an ideal choice for modern construction. Composite steel grating is made from a combination of materials, primarily consisting of steel and strong plastic resins, resulting in a lightweight yet durable solution. This innovative material is designed to withstand harsh weather conditions and heavy loads while maintaining its integrity, thus reducing the need for frequent replacements and cuts down on waste generation in the long run.

Moreover, the manufacturing process of composite steel grating typically involves less energy consumption compared to traditional metal alternatives. This energy efficiency translates into lower carbon emissions, contributing to a smaller ecological footprint for your project. Additionally, many composite grating products are designed with recycled materials, further enhancing their sustainability profile. By opting for composite steel grating, not only can project managers ensure a reliable and high-performance solution, but they are also making a conscious choice that supports environmental conservation and sustainability in the construction industry.