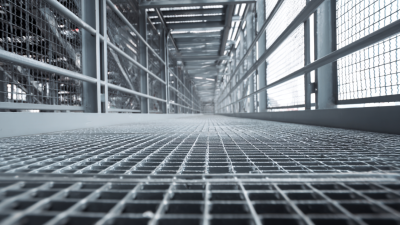

Mill Finish Grating is increasingly recognized in various industries for its numerous benefits, ranging from cost-effectiveness to durability. As engineers and contractors seek sustainable materials that do not compromise on performance, the demand for Mill Finish Grating solutions has steadily risen. According to a recent report by the Global Grating Market Analysis, the utilization of Mill Finish Grating is projected to grow by 15% annually, driven by its versatility in applications such as industrial flooring, walkways, and safety covers.

Industry expert Dr. Emily Carter, a well-respected authority in materials engineering, has stated, “Mill Finish Grating stands out for its ability to provide high strength and corrosion resistance at a lower cost compared to traditional grating systems.” This sentiment underscores the growing appeal of Mill Finish Grating, particularly in sectors that prioritize both efficiency and safety. As stakeholders continue to navigate the demands of modern construction and infrastructure development, understanding the top benefits of Mill Finish Grating can empower them to make informed decisions that enhance both performance and value.

Through this exploration, we will delve into the top ten benefits of Mill Finish Grating, providing insights that highlight its significance in today's competitive market. The advantages span from enhanced safety features to reduced maintenance costs, solidifying its place as an essential component in contemporary design and construction.

Mill finish grating has emerged as a preferred choice for various industrial applications due to its unique properties and advantages. One significant benefit is its enhanced resistance to corrosion. According to a report by the Steel Structure Painting Council, mill finish aluminum grating can withstand harsh environmental conditions, making it ideal for facilities exposed to moisture, chemicals, and extreme temperatures. This durability not only extends the lifespan of the grating but also reduces maintenance costs, which is a crucial factor in budget-conscious industrial projects.

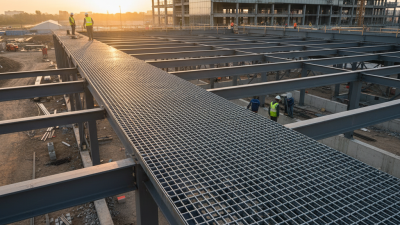

Moreover, the lightweight nature of mill finish grating significantly contributes to ease of installation and structural efficiency. A study conducted by the American Institute of Steel Construction indicates that using aluminum grating can reduce the overall weight of structures by up to 30% compared to traditional materials. This reduction in weight allows for simpler installation and can lead to savings on labor costs and support structures. Furthermore, mill finish grating is non-combustible, offering additional safety in hazardous industrial environments where fire resistance is a primary concern. The combination of durability, cost-effectiveness, and safety features makes mill finish grating a smart choice for various industrial applications.

Mill finish grating is increasingly recognized for its exceptional durability and strength, which sets it apart from alternative materials. According to a study by the American Institute of Steel Construction, mill finish products exhibit a resistance to corrosion that can significantly extend their lifespan, with some applications reporting up to 50 years of service without major degradation, particularly in challenging environments. This durability is largely attributed to the natural oxidation process of aluminum, which forms a protective layer against environmental factors such as moisture and chemicals, making it an ideal choice for industrial and architectural applications.

In comparison, traditional materials like painted or galvanized steel are more susceptible to rust and wear, often requiring regular maintenance and replacement, which can incur additional costs over time. The American Society for Testing and Materials (ASTM) states that the tensile strength of mill finish aluminum grating is comparable to that of mild steel, providing robust support while maintaining a significantly lighter weight. This combination of strength and reduced weight not only enhances load-bearing capacity but also simplifies installation processes, making mill finish grating a highly efficient choice for engineers and construction firms aiming for durability without compromising on integrity.

Mill finish grating is becoming an increasingly popular choice for long-term projects due to its outstanding cost-effectiveness. According to a report by the National Association of Architectural Metal Manufacturers, the initial costs associated with mill finish materials are significantly lower than their painted or galvanized counterparts. This price advantage allows project managers to allocate budget resources more effectively across other critical areas, enhancing overall project efficiency. Furthermore, the life cycle cost of mill finish grating is often favorable, as its durability minimizes replacement frequency and repair expenses over time.

Tips for enhancing the cost-effectiveness of your mill finish grating include adopting regular maintenance practices. By implementing a simple cleaning schedule, project managers can extend the lifespan of the grating significantly. Another suggestion is to utilize mill finish grating in non-corrosive environments, as this will maximize durability and minimize degradation threats. An industry report indicates that when used in appropriate settings, mill finish grating can outperform other types in longevity, yielding substantial long-term savings.

In addition, it’s crucial to consider the right application, as selecting mill finish grating for areas with less exposure to harsh elements can optimize its performance. A study by the American Iron and Steel Institute emphasizes that the functional benefits of mill finished products, such as strength and load capacity, provide invaluable return on investment for enduring structural demands. This makes mill finish grating an ideal option for various industrial applications, reinforcing its standing as a strategic choice for cost-conscious project planners.

| Benefit | Description | Long-Term Cost Implication |

|---|---|---|

| Durability | Resistant to corrosion and wear, ensuring longevity. | Reduces replacement costs over time. |

| Low Maintenance | Requires minimal upkeep due to its robust nature. | Saves on maintenance expenses. |

| Cost-Effective Production | Manufacturing processes result in lower initial costs. | Lower upfront investment helps budgets. |

| Versatility | Can be used in various applications across industries. | Reduces the need for multiple product types. |

| Safety | Enhanced slip resistance improves worker safety. | Lowers liability costs related to accidents. |

| Environmentally Friendly | Recyclable materials contribute to sustainability. | Can potentially reduce waste disposal costs. |

| Aesthetic Appeal | Natural finish enhances visual appeal for applications. | Can improve product value perception in design. |

| Lightweight | Easy to handle and install, reducing associated labor costs. | Saves on shipping and installation costs. |

| High Load Capacity | Designed to hold substantial weight effectively. | Minimizes need for additional reinforcement. |

| Customizability | Easily tailored to specific project requirements. | Reduces costs associated with off-the-shelf solutions. |

Mill finish grating is increasingly being recognized for its aesthetic appeal in modern architecture. The raw, unpolished appearance of mill finish grating adds a unique character to various design elements, blending industrial strength with minimalist aesthetics. This type of grating is not only functional, allowing for proper drainage and ventilation, but it also enhances the visual interest of spaces, making it an ideal choice for both indoor and outdoor applications.

Incorporating mill finish grating can evoke a contemporary vibe, especially in urban settings. Its neutral, metallic look complements a wide range of materials including wood, glass, and concrete, allowing architects and designers to create cohesive and visually striking environments. The subtle sheen of the finish can highlight structural elements while still maintaining an understated elegance, making it suitable for projects that aim to achieve both sophistication and durability.

Tips for using mill finish grating in your designs include considering its placement in areas that benefit from natural light, as the finish can reflect light and create dynamic visual effects. Additionally, pairing mill finish grating with vibrant colors or textured materials can further enhance its appeal, providing a striking contrast that draws the eye. Lastly, don't overlook the potential for creative patterns and layouts — innovative configurations can transform even the most utilitarian function into a captivating focal point in the overall design scheme.

Mill finish grating offers a range of environmental benefits that make it an excellent choice for construction projects. Unlike painted or coated alternatives, mill finish grating is produced without the use of harsh chemicals or finishes that can harm the environment. This natural state reduces the overall carbon footprint associated with production, contributing to greener building practices. Moreover, since mill finish grating does not require additional treatments or coatings, it minimizes waste and promotes resource efficiency.

Another key aspect of mill finish grating is its durability and longevity, which significantly reduces the need for replacements and repairs over time. This longevity supports sustainable construction by lowering the frequency of material consumption and waste generation. Additionally, mill finish grating is typically made from recyclable materials, allowing it to be repurposed at the end of its life cycle. This recyclability not only conserves natural resources but also further reduces the environmental impact of construction practices, aligning with the growing emphasis on sustainability in the industry.