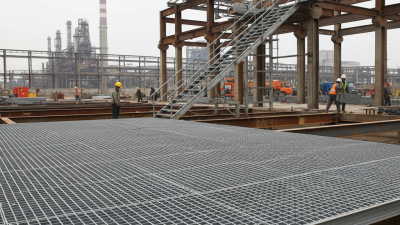

As the construction industry continues to evolve, the demand for durable and efficient materials is ever-growing. Among these, "Hot Dipped Steel Grating" stands out as a top choice for both commercial and industrial applications. Renowned expert in structural engineering, Dr. Emily Carter, emphasizes the significance of quality in this domain, stating, "When selecting materials for projects, the longevity and resilience of hot dipped steel grating can significantly impact the overall success and safety of the structure."

In 2025, the market for Hot Dipped Steel Grating is expected to expand, with numerous options available to meet diverse project requirements. The unique manufacturing process of hot dipping ensures a superior coating that enhances corrosion resistance and durability, making it a preferred choice for many engineers and project managers. With the right selection of grating, one can achieve not only functionality but also aesthetic appeal, as these products come in various designs and finishes.

This article will explore the top 10 best hot dipped steel grating options available in 2025, focusing on their features, applications, and advantages to help you make informed decisions for your upcoming projects. Whether you are in need of grating for walkways, platforms, or drainage systems, understanding the top choices will guide you in selecting the best solutions for your construction needs.

When it comes to construction projects, the choice of materials directly impacts durability and long-term performance. Among the various options available, hot dipped steel grating stands out for its admirable properties, including resistance to corrosion and physical wear. In fact, industry reports indicate that structures utilizing hot dipped steel grating experience a significant reduction in maintenance costs - up to 30% over a 10-year period - compared to those made with traditional materials.

The most popular hot dipped steel grating materials encompass galvanized steel, stainless steel, and carbon steel. Galvanized steel, due to its double-layer protection from zinc coatings, is favored in harsh environments, providing a lifespan that often exceeds 20 years even in coastal areas. Stainless steel, known for its superior resistance to rust and staining, is ideal for environments where hygiene and aesthetics are paramount, often being specified in food processing and pharmaceutical applications. Lastly, carbon steel, while generally less resistant to corrosion, can be treated to enhance its durability and is often selected for heavy load-bearing applications.

Choosing the right material is crucial for project architects and engineers, especially considering that nearly 40% of all construction failures are linked to material degradation over time. By investing in high-quality hot dipped steel grating, professionals can ensure their projects stand the test of time, delivering value and performance that meet or exceed industry standards.

When selecting hot dipped steel grating for your projects,

key performance metrics such as load capacity

and corrosion resistance play a crucial role. Load capacity determines how much weight

the grating can support without failure, making it essential for applications in industries

like construction and manufacturing. It's vital to choose a grating system that meets or

exceeds the load requirements of your specific application to ensure safety and durability.

Corrosion resistance is another critical factor to consider, especially in environments

exposed to moisture or harsh chemicals. Hot dipped galvanization provides an effective barrier

against corrosion, extending the lifespan of the steel grating. Look for products that comply

with relevant industry standards for corrosion resistance to ensure long-lasting performance in

challenging conditions.

Tips: Always consult with manufacturers about the specific

load ratings and corrosion resistance certifications of the steel grating you're considering.

Additionally, consider the environmental conditions where the grating will be installed, as

this can significantly affect its performance. Finally, regular maintenance can further enhance

the longevity of steel gratings, so incorporate inspection schedules into your project planning.

When it comes to grating options, hot-dipped steel grating stands out for its superior durability and corrosion resistance. However, projects often require a careful consideration of cost-effectiveness against other grating types such as fiberglass or aluminum. The initial investment in hot-dipped steel may be higher, but its long-term benefits, such as reduced maintenance costs and extended lifespan, can result in significant savings over time.

Tips: When selecting grating for your project, the environmental conditions should influence your choice. For instance, hot-dipped steel is highly recommended for outdoor applications exposed to moisture, while aluminum and fiberglass might suit areas with less wear and tear.

Furthermore, the choice of material should align with the intended use. Hot-dipped steel grating excels in heavy-duty environments, where load-bearing capacity is paramount. In contrast, if weight and ease of installation are priorities, lighter options like fiberglass grating can be advantageous. Evaluating these factors will ensure that your investment yields the best performance and value.

Hot-dipped steel grating is increasingly recognized for its sustainability benefits, particularly as the global market for hot-dip galvanized steel is projected to grow from $17.36 billion in 2024 to $20.12 billion by 2025. This growth is driven by a rising demand for durable and corrosion-resistant materials, which are essential for sustainable construction practices. The production process of hot-dip galvanized steel significantly reduces the need for frequent replacements, ultimately lessening environmental impact. According to industry reports, the galvanized steel market was valued at approximately $241.87 billion in 2024, indicating a robust demand fueled by its longevity and environmental resilience.

**Tips:** When selecting hot-dipped steel grating for your projects, consider integrating it with eco-friendly designs to maximize sustainability. Additionally, look for suppliers who prioritize environmentally sound manufacturing processes to further enhance the benefits of your chosen materials. As the industry shifts toward greener solutions, choosing the right materials becomes increasingly critical in reducing your carbon footprint.

The corrosion resistance of hot-dipped galvanized steel not only extends the lifespan of materials but also reduces the need for protective coatings that can be harmful to the environment. A study from 2022 highlighted the need for innovative strategies to combat corrosion, positioning hot-dip galvanizing as a leading solution in achieving sustainable growth in construction and infrastructure.

In 2025, the landscape of hot dipped steel grating is expected to evolve significantly, spurred by advancements in coating technologies. Recent industry analysis indicates that the global market for steel gratings is projected to reach $3 billion by 2025, driven by the need for enhanced durability and corrosion resistance in various applications, including infrastructure and industrial sectors. Innovations in protective coatings, such as powder coating and advanced galvanization techniques, are set to improve the longevity and performance of steel gratings while reducing maintenance costs.

Moreover, the trend towards sustainability has led to the development of eco-friendly coating solutions. According to the latest report by MarketsandMarkets, the demand for green coatings is expected to grow at a CAGR of 5.5% through 2025. This shift not only aligns with global environmental standards but also caters to customer preferences for products that minimize ecological impact. The focus on these innovative coating methods is likely to change consumer purchasing behavior, making coated steel gratings increasingly popular in various construction and industrial projects due to their superior performance attributes.

| Rank | Material Type | Coating Technology | Durability (Years) | Applications | Price Range (per sq. ft.) |

|---|---|---|---|---|---|

| 1 | Mild Steel | Hot Dip Galvanizing | 15 | Industrial Facilities | $5 - $8 |

| 2 | Stainless Steel | Electroplating | 30 | Food Processing | $10 - $15 |

| 3 | Aluminum | Anodizing | 20 | Transportation | $8 - $12 |

| 4 | Carbon Steel | Powder Coating | 10 | Construction | $4 - $6 |

| 5 | Galvanized Steel | Hot Dip Galvanizing | 25 | Wastewater Treatment | $6 - $9 |

| 6 | Mild Steel | Zinc Coating | 12 | Marine Applications | $5 - $7 |

| 7 | Stainless Steel | PVD Coating | 40 | Architectural Design | $15 - $20 |

| 8 | Composite | Eco-Friendly Coating | 20 | Sustainable Design | $7 - $10 |

| 9 | High Carbon Steel | Ceramic Coating | 25 | Mining Industry | $9 - $14 |

| 10 | Fiberglass | UV Resistant Coating | 15 | Electrical Applications | $11 - $16 |