When embarking on a project that requires durable flooring solutions, the choice of materials is critical. Press Welded Steel Grating is a popular option among architects and contractors. According to industry expert John Smith, “Selecting the right steel grating can significantly impact both safety and aesthetics.” His words remind us of the weight our decisions carry in such projects.

Press Welded Steel Grating offers strength, versatility, and superior drainage. It’s essential to consider several factors when making your selection. The dimensions, load requirements, and environment are key elements. Understanding these aspects can lead to better outcomes. Ignoring them may result in costly mistakes down the line.

The nuances of Press Welded Steel Grating deserve thoughtful reflection. Is the weight capacity adequate for your needs? Have you considered the maintenance requirements? A rushed choice can lead to regrettable consequences. Take the time to assess your specific project needs to ensure durability and functionality.

When choosing press welded steel grating, several factors come into play. First, consider the load capacity. This relates directly to the project's demands. If heavy machinery will traverse the grate, it must be robust enough to withstand that weight. Knowing the maximum load can save you from costly replacements later.

Another factor is the spacing of the bars. Different configurations provide varying levels of safety and structural integrity. For areas where small items may fall through, tighter spacing is essential. However, this can also affect drainage. Balancing these needs is crucial, as each project may present unique challenges.

Surface treatment is also important. Steel grating can come with different coatings or finishes. Options include galvanizing or powder coating for rust prevention. This choice affects durability. Consider the environment where it will be installed. Is it indoors or outdoors? The weather exposure plays a big role in the longevity of the steel.

When considering steel grating for your project, understanding the different types available can significantly impact your decision. There are various styles, including press-welded, molded, and laser-cut grating. Press-welded grating is especially popular due to its strength and durability. It is made by pressing and welding together flat bars. This method creates a robust product that can withstand heavy loads.

Selecting the right type involves assessing your project needs. Think about the load capacity, environmental factors, and the amount of foot traffic. If you require drainage, look for designs with spaces between the bars. Consider potential rusting issues too. Sometimes, coatings can help, but they may not be foolproof.

A few tips can guide your choices. Always calculate the weight that the grating needs to handle. Also, don’t underestimate the importance of aesthetics. The grating should fit well with the overall design. Lastly, it’s critical to factor in costs. Sometimes the cheapest option may not offer long-term value. Pay attention to your specific requirements to find the best fit.

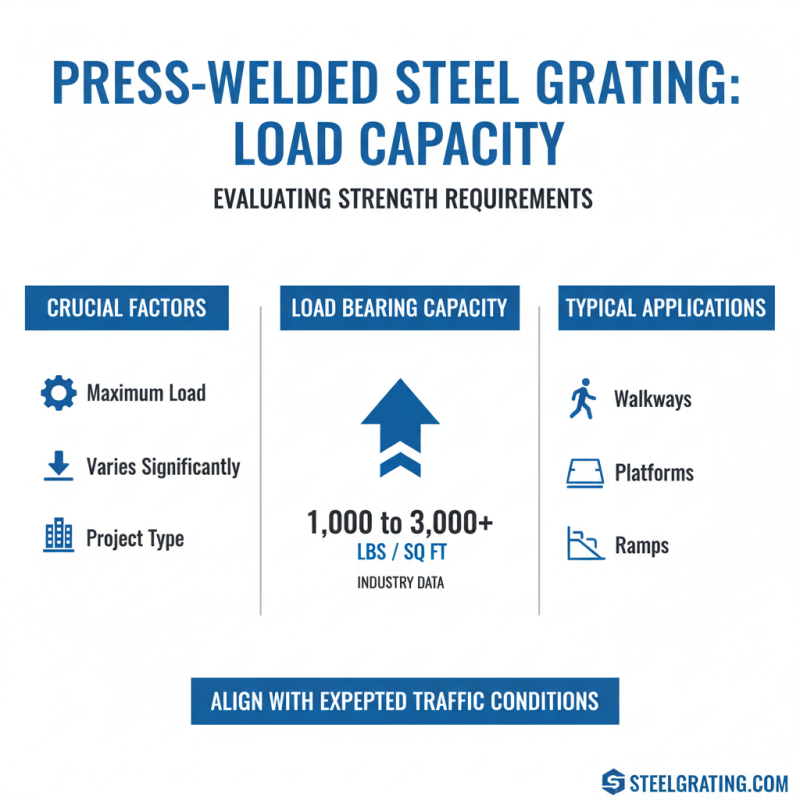

When evaluating load capacity and strength requirements for press welded steel grating, consider several crucial factors. The maximum load that grating can support varies significantly. According to industry data, a well-designed steel grating can handle loads from 1,000 to over 3,000 pounds per square foot. This specification is vital for projects such as walkways, platforms, and ramps. The grating must align with the expected traffic conditions.

The thickness and material of the steel greatly influence performance. Some projects require heavier materials to withstand intense use. Regularly, a thickness of 1-inch can significantly improve strength. Additionally, understanding the spacing of the bearing bars is essential. Closer spacing increases load capacity but may result in higher costs. Notably, wrong choices can lead to safety hazards or unplanned expenses. If the project demands high loads, consider reviewing load test data or seeking expert opinions. A miscalculation in load capacity could compromise the structure's integrity. Always prioritize rigorous evaluations to ensure safety and efficiency.

When selecting press welded steel grating, corrosion resistance is crucial. Various environmental factors influence the longevity of materials. Data from the American Galvanizers Association shows that galvanized steel can offer over 50 years of lifespan in harsh conditions. This is important, especially in corrosive settings like coastal areas or chemically aggressive environments.

Material durability should also be assessed carefully. The use of different alloys can affect strength and longevity. For instance, stainless steel grating shows higher resistance to rust compared to carbon steel. However, it may come at a higher initial cost. This decision often forces project managers to reflect on budget versus long-term benefits. An analysis from the International Steel Institute suggests that investing in higher-quality materials can ultimately reduce maintenance costs.

It's essential to consider potential drawbacks. While durable materials resist wear, they may require specialized tools for installation. This complication can delay projects and increase labor expenses. Alertness to these factors is key in making a well-informed decision.

When planning a project involving press welded steel grating, budgeting is crucial. Understanding material costs can help avoid financial pitfalls. Prices can vary widely based on thickness, load capacity, and surface finishes. Every choice impacts your budget. Consider how the design will influence the total expense.

One tip is to compare quotes from different suppliers. Always ask for detailed breakdowns. This can reveal hidden costs. Do not overlook the expense of installation. It can make up a significant portion of the budget. Ensure your financial projections account for this.

Another aspect to consider is the lifespan of the grating. Higher upfront costs can save money long-term. Durability often equals less replacement and maintenance. Reflecting on your specific needs and usages can guide choices. Find a balance between quality and cost.