Choosing the right Marine Walking Steel Grating is crucial for various marine applications. According to industry reports, the global marine grating market is projected to grow significantly over the next few years. Demand is driven by safety, durability, and efficiency.

Marine Walking Steel Grating is designed to withstand harsh marine environments. These gratings provide essential traction and safety for personnel. However, selecting the wrong type can lead to costly implications. Studies show that improper grating can increase accident rates by up to 30%.

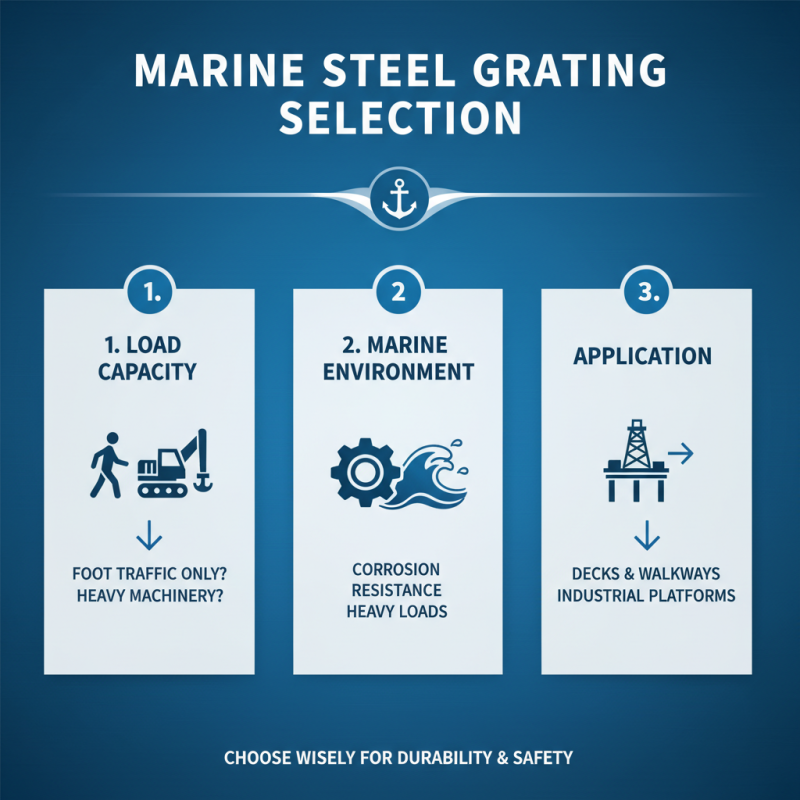

Attention to detail is vital when making your choice. Factors like material composition, corrosion resistance, and load capacity should guide your decision. Surveys suggest that over 40% of projects fail due to inadequate grating selection. Reflecting on such data can prevent potential risks and enhance operational success.

Marine walking steel grating is an essential component in numerous marine applications. Its primary use is to provide safety underfoot in areas prone to water accumulation. You can find it on docks, ships, and offshore platforms. These gratings allow water to drain away, preventing slips and falls. The design features open spaces that promote visibility and air circulation.

When choosing marine walking steel grating, consider the material. Stainless steel is often preferred due to its corrosion resistance. Galvanized grating is also popular, but it may require more maintenance. Think about the load capacity too. Different applications can require specific strength levels for safety.

Tip: Check for compliance with marine standards. Not all grating is created equal. Look for certifications that ensure suitability for marine environments. Another tip: evaluate the spacing between the bars. Spaces that are too wide can pose a tripping hazard. Remember, poorly chosen grating might lead to injuries or accidents. So take your time during the selection process.

When choosing marine walking steel grating, evaluating load capacity is crucial. Marine environments present unique challenges like corrosion and heavy loads. Be mindful of how the grating will be used. Will it support foot traffic only? Or will it take on heavier machinery? These factors must guide your choice.

Consider the material’s strength. Not all steel grates are alike. The right thickness and spacing can make a significant difference. Choose a thicker option if in doubt. This can help prevent bending or breaking under pressure. Marine conditions can be unforgiving, so it’s wise to be cautious.

Evaluate the grating's design. Think about drainage and slip resistance. Water can accumulate on grates, especially in coastal regions. Look for features that enhance safety during rain or rough conditions. Sometimes, aesthetics are important too. Choose a style that fits your environment while still being functional. Remember, the goal is not just to walk on them but to ensure safety and durability.

Choosing the right material for marine walking steel grating is crucial. Corrosion resistance should be a top priority. Marine environments are harsh. Saltwater, humidity, and other factors contribute to rapid deterioration. Selecting materials that resist these factors can extend the lifespan of the grating.

Stainless steel is common. It's highly resistant to rust and corrosion. However, not all stainless steel grades offer the same level of durability. Some might struggle under extreme conditions. Consider options like galvanized steel. This offers additional protection through a zinc coating. Remember, cost often influences choices but do not compromise on quality.

Always assess the installation site. Factors like exposure to seawater or chemical spills matter. Skimping on details, such as maintenance routines, can lead to poor performance. An informed choice today can prevent costly replacements tomorrow. Regular inspections of grating help identify potential issues early.

When choosing marine walking steel grating, safety features are paramount. Anti-slip surfaces are essential for preventing accidents. A high-friction coating can significantly reduce the risk of slipping. Look for grates that are tested for slip resistance in wet conditions. This feature proves vital for areas exposed to water.

Load distribution specifications deserve careful attention. It's crucial to understand how weight will be dispersed across the grating. Inadequate load distribution can lead to structural failures. Ensure the selected grating can handle potential loads. Over time, wear can affect these specifications, requiring regular assessments.

Many overlook the importance of maintenance. Regular inspections can reveal unseen issues. Relying solely on initial specifications may be risky. Materials can degrade in harsh marine environments. Familiarize yourself with the installation process. Poor installation may compromise safety features. These factors are often debated but are essential to thoughtful decision-making.

When budgeting for marine walking steel grating, it’s crucial to understand all potential costs. The type of material influences price significantly. Stainless steel tends to be pricier than carbon steel, but offers better corrosion resistance. Assess your specific marine environment before purchasing. Harsh environments may require higher-quality materials, which can increase upfront costs.

Installation expenses also play a vital role. Skilled labor for installation isn’t cheap. Consider the accessibility of the site for efficient installation. If the area is hard to reach, costs might rise. It’s wise to get multiple quotes from contractors. Some may have hidden fees or charges that could surprise you later.

Don't forget maintenance costs. Regular inspections and occasional repairs are necessary. Over time, neglect can lead to larger expenses. Calculate the long-term implications of your choice. Sometimes cheaper options may lead to risks down the line. Think carefully about these factors to make a well-informed choice.

| Tip | Description | Cost Factor | Budget Estimate |

|---|---|---|---|

| Durability | Choose grating designed to withstand marine environments. | High impact resistance, corrosion resistance | $30 - $50 per square foot |

| Weight Load Capacity | Select based on anticipated traffic and load requirements. | Structural integrity and design factors | $25 - $40 per square foot |

| Safety Features | Look for anti-slip surfaces to enhance safety. | Safety standards and material treatments | $20 - $35 per square foot |

| Maintenance Requirements | Consider options requiring less upkeep for cost-efficiency. | Long-term maintenance costs | $10 - $30 per square foot per year |

| Compliance with Standards | Ensure products meet relevant industry regulations. | Certification and compliance testing | $15 - $25 per square foot |