In modern construction and infrastructure, Steel Grating has emerged as a fundamental component, offering both strength and versatility in various applications. According to a report by the Global Steel Grating Market, the industry is projected to reach $5.9 billion by 2026, driven by increasing demand across sectors such as construction, oil and gas, and wastewater management. The durability and anti-corrosive properties of steel grating make it ideal for heavy-duty environments, ensuring safety and longevity in structures. Furthermore, the design flexibility allows for a wide range of configurations, meeting the specific needs of diverse projects. As urbanization continues to accelerate, the reliance on steel grating for effective drainage, walkway systems, and security applications will only grow, solidifying its essential role in contemporary infrastructure.

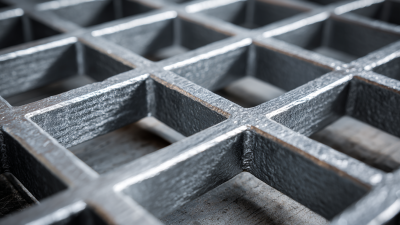

Steel grating has become a fundamental component in modern construction and infrastructure. Its practical applications and benefits make it an ideal choice for various projects, from pedestrian walkways to heavy industrial platforms. Understanding the basics of steel grating involves recognizing its composition, versatility, and durability. Made from steel bars that are welded or inserted together, it offers a resilient solution that can withstand heavy loads while allowing for efficient drainage and ventilation, making it suitable for both outdoor and indoor use.

Tip: When selecting steel grating for your project, consider the load requirements and environmental conditions to ensure optimal performance and longevity. Choosing the right spacing and thickness can also impact safety and functionality.

In addition to its strength, steel grating is valued for its quick installation and low maintenance. It can be easily fabricated to fit specific designs and sizes, adapting to the unique needs of various structures. This flexibility not only streamlines the construction process but also allows for aesthetic customization when required.

Tip: Regular maintenance checks can prevent rust and corrosion, prolonging the life of steel grating. Applying protective coatings can further enhance durability, especially in harsh environments.

Steel grating plays a pivotal role in modern construction and infrastructure, offering several key advantages that make it an indispensable material. One of the most significant benefits is its strength-to-weight ratio. Steel grating is robust enough to support heavy loads while remaining lightweight, which facilitates easier handling and installation. This characteristic is particularly advantageous in environments where structural integrity and weight are critical considerations, such as bridges, walkways, and industrial facilities.

Steel grating plays a pivotal role in modern construction and infrastructure, offering several key advantages that make it an indispensable material. One of the most significant benefits is its strength-to-weight ratio. Steel grating is robust enough to support heavy loads while remaining lightweight, which facilitates easier handling and installation. This characteristic is particularly advantageous in environments where structural integrity and weight are critical considerations, such as bridges, walkways, and industrial facilities.

Another advantage of steel grating is its superior durability and resistance to harsh weather conditions. Unlike other materials, steel grating is less susceptible to corrosion when coated properly, ensuring a longer lifespan and reducing maintenance costs. Additionally, the open design of steel grating enhances drainage and ventilation, making it ideal for applications in areas prone to water accumulation or airflow restrictions. This combination of strength, longevity, and practicality makes steel grating a vital component for architects and engineers striving to create safe and efficient structures.

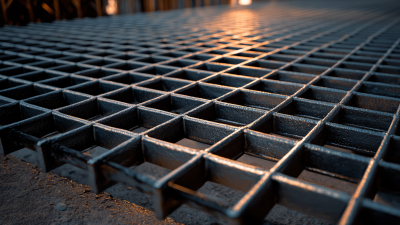

Steel grating plays a pivotal role in modern construction and infrastructure, offering a versatile solution for various applications. One of the primary uses is in flooring for industrial facilities, where the grating provides a durable surface that allows for ventilation and light penetration. This feature is particularly beneficial in factories and warehouses, where safety and efficiency are paramount. Additionally, steel grating is commonly employed in bridges and walkways, ensuring both structural integrity and slip resistance, vital for pedestrian safety.

When considering steel grating for your construction projects, it’s important to keep a few tips in mind: choose the right type based on load requirements and environment, consider galvanized options for corrosion resistance, and ensure proper installation to maximize performance. Another application of steel grating is in drainage systems, where it's used as a cover that allows water to flow while keeping debris out. This helps maintain clean and efficient water management systems in urban infrastructure.

By exploring these diverse applications, we can appreciate how steel grating enhances safety, functionality, and longevity in various construction projects, supporting the evolving needs of modern infrastructure.

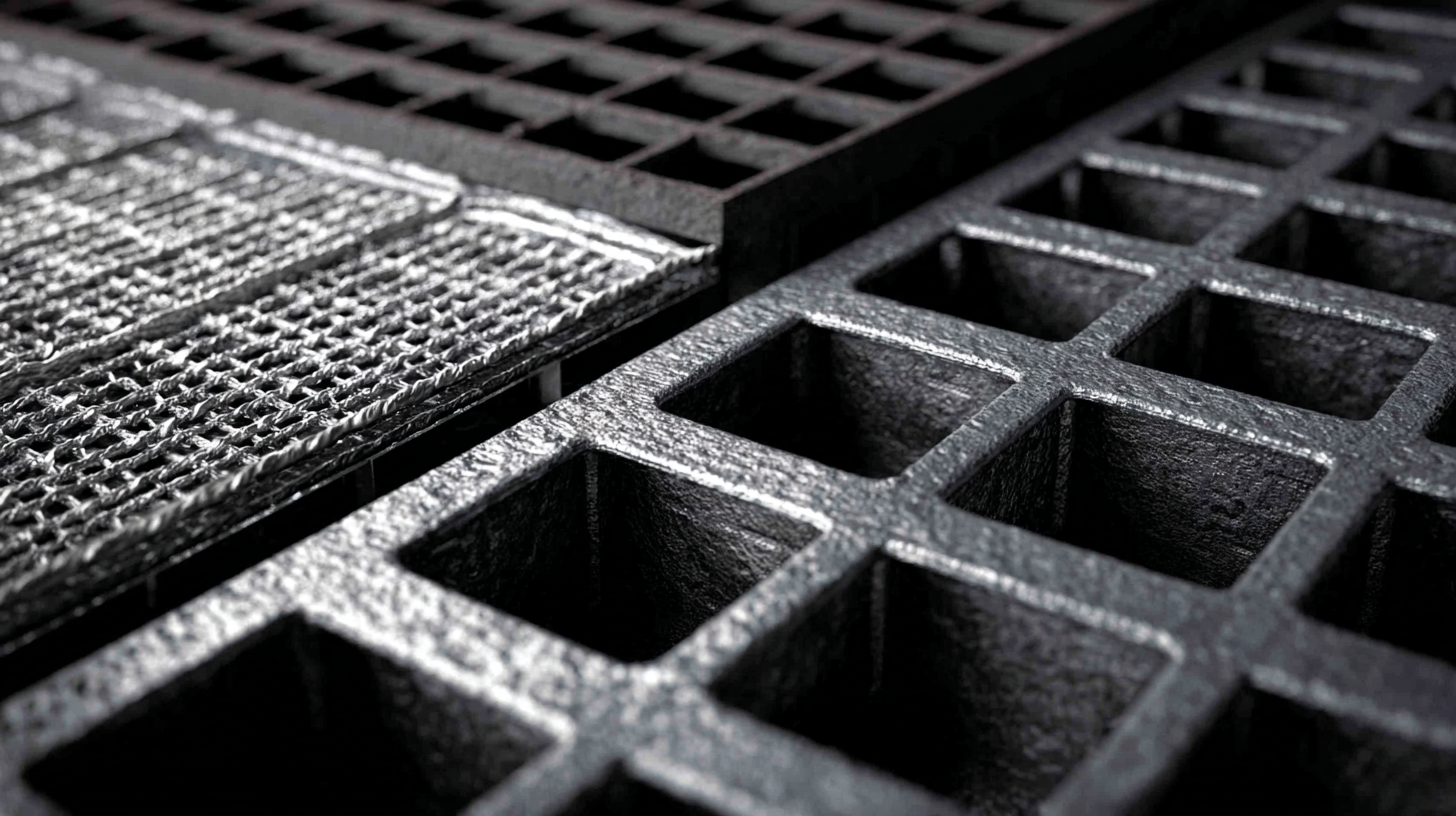

When selecting the right steel grating for your project, it’s essential to consider various factors that affect both functionality and safety. Steel grating comes in different types and styles, each suited for specific applications. For example, heavy-duty grating is ideal for industrial settings where load-bearing capacity is critical, while lighter options may suffice for residential or decorative uses. The choice of material, such as galvanized or stainless steel, can also impact the longevity and corrosion resistance of the grating in various environmental conditions.

Additionally, the design of the grating plays a pivotal role in drainage and slip resistance, especially in areas that are prone to water accumulation. Incorporating linear drains alongside steel grating systems can enhance water flow management, which is an aspect increasingly recognized in modern construction. Balancing aesthetic considerations with practical performance will guide you in making an informed decision, ensuring that the selected steel grating complements not only the functionality but also the overall design of your infrastructure.

Steel grating is a durable and versatile material widely used in modern construction and infrastructure. However, ensuring its longevity requires proper maintenance. Regular inspection is crucial; studies indicate that neglecting to check for signs of wear can reduce the lifespan of steel grating by up to 50%. Notably, a report from the American Institute of Steel Construction highlights that routine maintenance can prolong the life of steel gratings to over 25 years, significantly improving cost-effectiveness in large-scale projects.

One of the key maintenance tips is to conduct periodic cleaning to eliminate dirt, debris, and corrosive materials. Research shows that accumulated grime can lead to accelerated corrosion and, ultimately, structural failure. Employing a pressure washer and mild detergents can effectively restore the integrity of the grating. Additionally, applying protective coatings, such as galvanization or powder coating, can further enhance corrosion resistance. According to data from the Steel Grating Institute, assemblies that are properly coated can withstand harsh environmental conditions, thus maintaining their functionality and safety in the long term.

Regular maintenance and protective measures ensure that steel grating installations remain reliable fixtures in our infrastructural landscape.