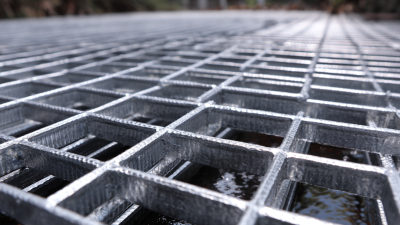

In the rapidly evolving world of industrial materials, sourcing high-quality mill finish grating has become a critical focus for manufacturers and contractors alike. According to a recent market analysis published by Research and Markets, the global grating market is expected to reach approximately $5.45 billion by 2025, driven by the increasing demand for safety and durability in construction and engineering projects. Mill finish grating, known for its cost-effectiveness and versatility, plays an essential role in various applications, from walkways and platforms to industrial drainage systems.

However, navigating the complexities of global sourcing can be challenging, as quality standards and supplier reliability vary widely across regions. This blog aims to provide seven proven tips for effectively sourcing high-quality mill finish grating, ensuring that your projects are not only successful but also meet stringent safety and performance standards.

When sourcing high-quality mill finish grating globally, understanding the grades and standards associated with mill finish products is essential. Mill finish grating typically refers to the surface finish of steel or aluminum grates that have not undergone any additional treatments. The quality of these products is often determined by their material composition, fabrication methods, and adherence to industry standards. Familiarity with key grading systems, such as ASTM or ANSI specifications, provides a reliable framework for evaluating the quality and suitability of grating for specific applications.

Additionally, recognizing the global variations in standards can significantly impact sourcing decisions. Different countries may employ distinct grading criteria, which influences the consistency and performance of mill finish grating. Engaging with reputable suppliers who have a clear understanding of local and international standards ensures that your procurement process yields reliable and high-quality grates. By prioritizing knowledge of these grades and standards, businesses can elevate their sourcing strategies, leading to enhanced durability and functionality in their projects.

As the global market for mill finish grating evolves, understanding current sourcing trends is essential for businesses aiming to secure high-quality products. The anticipated growth in the Contract Development and Manufacturing Organization (CDMO) sector, projected to reach $465.24 billion by 2032, signifies an increasing demand for versatile and reliable manufacturing processes. Companies are now looking to leverage advancements in technology that streamline sourcing operations and enhance product quality, all while keeping an eye on costs.

Emerging markets are reshaping the landscape of mill finish grating sourcing. The focus has shifted towards suppliers who can not only provide quality materials but also adapt to changing consumer preferences and sustainable practices. As companies survey their readiness for AI adoption, it becomes evident that integrating intelligent systems in procurement can significantly enhance decision-making and operational efficiency. By harnessing insights from data analytics, businesses can identify reliable suppliers and ensure compliance with industry standards, ultimately fostering a more resilient supply chain in this competitive global environment.

Navigating the complexities of global regulations is crucial when sourcing high-quality mill finish grating. Different countries have varying compliance requirements that can greatly impact your sourcing process. Familiarizing yourself with these regulations not only ensures that your products meet safety and quality standards but also helps avoid costly delays and legal issues. For instance, understanding material specifications and safety certifications in the target market can greatly influence supplier selection and product usage.

Moreover, it’s essential to stay informed about international trade agreements and tariffs that may apply to grating products. Such knowledge allows for better strategic planning when sourcing from abroad. Emphasizing due diligence on the part of suppliers, including their adherence to environmental regulations and labor laws, can further mitigate risk. Utilizing a compliance checklist can streamline the process, ensuring that all necessary documentation is in order, from material certifications to shipping information, ultimately leading to a smoother global supply chain operation.

| Tip Number | Tip | Key Compliance Requirement | Region | Notes |

|---|---|---|---|---|

| 1 | Research Local Standards | ISO 9001 Certification | Global | Ensure suppliers comply with international quality management standards. |

| 2 | Evaluate Supplier Ratings | Third-Party Audits | Europe | Choose suppliers with a strong track record and positive reviews. |

| 3 | Inspect Manufacturing Facilities | Safety Regulations Compliance | Asia | Regular on-site inspections help verify compliance with safety standards. |

| 4 | Request Samples | Material Certification | North America | Always verify material quality through sampling before placing bulk orders. |

| 5 | Understand Export Regulations | Customs Compliance | Latin America | Ensure that all exported goods meet local and international customs regulations. |

| 6 | Check Sustainability Practices | Environmental Compliance | Global | Select suppliers who follow sustainable manufacturing practices. |

| 7 | Maintain Clear Communication | Contractual Agreements | Global | Establish clear expectations and terms to avoid misunderstandings. |

When it comes to sourcing high-quality mill finish grating, maximizing cost-effectiveness is essential for ensuring that companies maintain a competitive edge in the market. According to a recent report by the Global Grating Association, the demand for mill finish grating is expected to increase by 5% annually, driven by infrastructure development and industrial expansion. Sourcing strategies that focus on bulk purchasing and negotiating long-term contracts can significantly reduce costs. By leveraging volume discounts, businesses can lower their unit price and boost their overall profit margins, allowing them to allocate resources to other vital areas of operation.

Furthermore, utilizing advanced sourcing platforms can enhance transparency and reduce overhead costs. A study from the Procurement Insights Institute indicates that companies using digital sourcing tools can save between 10% to 30% on procurement expenditures. Additionally, fostering relationships with reputable suppliers who prioritize quality can mitigate risks associated with sourcing inferior products, which often result in higher replacement costs. Integrating quality assessments into the sourcing process ensures that the materials meet industry standards, thereby providing not only cost savings but also long-term value and reliability in applications across various sectors.

When sourcing high-quality mill finish grating, assessing supplier reliability and product quality is crucial. Key metrics for evaluating suppliers include their manufacturing certifications, historical performance, and adherence to industry standards. Certifications such as ISO 9001 demonstrate a commitment to quality management systems, ensuring that the products meet specific quality criteria. Additionally, reviewing a supplier's historical performance through customer feedback, case studies, and product consistency can provide insights into their reliability.

Another important metric is the supplier's responsiveness and ability to accommodate customization requests. A reliable supplier should have a proactive communication strategy, enabling quick responses to inquiries and the flexibility to adjust to project-specific requirements. This capability not only reflects the supplier's dedication to customer satisfaction but also indicates their operational efficiency.

By focusing on these evaluation criteria, businesses can confidently partner with suppliers who consistently deliver high-quality mill finish grating, reducing risks associated with poor-quality products.