In today’s construction and manufacturing landscape, the selection of materials plays a crucial role in determining the overall durability and cost-effectiveness of projects. Mill Finish Steel Grating has emerged as a popular choice for various applications due to its unique properties and advantages. According to the latest industry report by the Steel Grating Manufacturers Association, steel grating can provide up to 60% more load-bearing capacity compared to traditional materials, while reducing maintenance costs by an astounding 30%. By strategically integrating Mill Finish Steel Grating into your projects, not only can you enhance the longevity and safety of structures, but you can also optimize project budgets effectively. This blog aims to explore the best practices for maximizing the durability and cost efficiency of Mill Finish Steel Grating, providing insights drawn from industry data and expert recommendations.

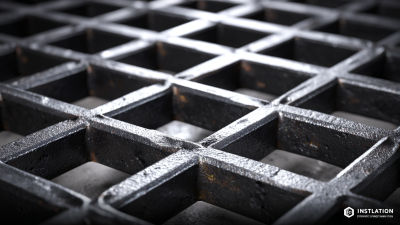

Mill finish steel grating is a versatile and efficient choice for a variety of construction projects. Its key features include a robust, open design that provides excellent drainage and ventilation, making it suitable for industrial environments where spills and moisture are prevalent. The raw finish of this type of grating, achieved through the manufacturing process, ensures minimal surface treatment, resulting in lower initial costs compared to other finishes. Additionally, the inherent strength of steel allows for high load-bearing capacity, which makes it ideal for heavy-duty applications.

The benefits of mill finish steel grating extend beyond cost savings. It requires minimal maintenance due to its durable nature, which means reduced long-term costs and less downtime for repairs. Furthermore, its lightweight structure simplifies installation, reducing labor costs and project timelines. With its resistance to wear and tear, mill finish steel grating stands as an excellent option for any project aimed at maximizing both durability and cost efficiency. Choosing this material not only enhances the performance of your infrastructure but also contributes to sustainable building practices by minimizing waste through its longevity.

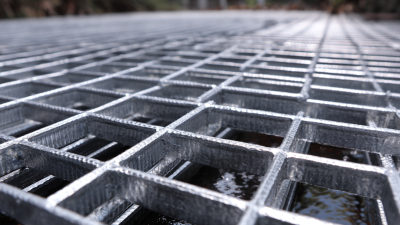

When considering the durability and performance of mill finish steel grating, several key factors come into play. First and foremost, the material composition is critical; primarily composed of carbon steel, these gratings often undergo hot-dip galvanization to enhance corrosion resistance. According to a report by the National Association of Architectural Metal Manufacturers (NAAMM), properly galvanized steel can extend the lifespan of grating systems to upwards of 30 years in moderate environments, significantly reducing long-term costs associated with replacement and maintenance.

Loading conditions also significantly impact the performance of steel grating. The American National Standards Institute (ANSI) outlines load classifications that ensure grating can withstand anticipated traffic and load impacts. Choosing the correct type of grating, such as welded, swage-locked, or press-locked variants, aligns with project requirements while optimizing weight and strength. Additionally, environmental factors, including exposure to chemicals and moisture, must be evaluated as they can drastically affect the integrity of the grating. By understanding these variables, project managers can select the ideal steel grating solutions to enhance durability and optimize overall cost-effectiveness.

| Factor | Description | Impact on Durability | Cost Implication |

|---|---|---|---|

| Material Quality | The grade of steel used in the grating | Higher quality materials enhance corrosion resistance. | Initial investment may be higher, but lowers maintenance costs. |

| Surface Finish | Finish type, e.g., mill finish vs. coated | Coated finishes can provide extra protection from environmental factors. | Coating adds cost but extends lifespan. |

| Load-Bearing Capacity | Maximum load the grating can support without failure | Higher capacity reduces potential for damage under heavy loads. | Investing in higher capacity grating may increase upfront costs. |

| Environmental Conditions | Exposure to moisture, salts, or chemicals | Environmental stress can lead to quicker deterioration. | Increased maintenance may be needed in harsh environments. |

| Installation Quality | Skill level and technique used during installation | Proper installation prevents future structural issues. | Quality installation may incur higher labor costs. |

When considering cost-effective strategies for sourcing and installing mill finish steel grating in your projects, it's essential to explore innovative ways to enhance both durability and expense management. Recent analyses indicate that integrating renewable energy technologies can significantly lower operational costs. For instance, grid-scale storage solutions enable facilities using steel grating to harness excess energy during off-peak hours, allowing them to stabilize their energy expenses. Reports suggest that by 2050, transitioning to renewable energy sources could not only reduce electricity costs but also improve the resilience of energy supply, critical for construction material projects.

Moreover, the International Energy Agency emphasizes a sustainable approach to grid planning, advocating for intelligent investment strategies that factor in climate resilience. With property development increasingly reliant on green energy, sourcing steel grating from manufacturers that prioritize sustainable practices can lead to mutual benefits. By combining these strategies, businesses can optimize their supply chain, ensuring that the procurement and installation of mill finish steel grating are aligned with both cost-effectiveness and environmental stewardship in the face of evolving energy policies.

Maintaining mill finish steel grating is essential for ensuring its longevity and performance in various applications. One of the best practices is regular cleaning to prevent the buildup of debris and corrosive substances. Employing a simple pressure wash or a scrub with mild detergent can help keep the grating surfaces clear and intact. It is also important to inspect the grating periodically for signs of wear or damage, such as cracks or rust, which can compromise its strength and safety.

Another crucial aspect of maintenance is applying a protective coating if the environment is particularly harsh. This can involve using a rust-inhibiting paint or a specialized sealant to create a barrier between the steel and the elements. Additionally, ensuring proper drainage around the grating can minimize exposure to water, which can accelerate rust formation. By following these best practices, project managers can significantly enhance the durability and cost efficiency of mill finish steel grating, ensuring it meets the demands of their projects effectively.

When considering grating options for construction projects, mill finish steel grating offers distinct advantages over other types in terms of durability and cost efficiency. A recent examination of energy-efficient technologies highlights that opting for mill finish steel can result in considerable energy savings and lower carbon emissions during production processes. For instance, utilizing mill finish steel grating can reduce maintenance costs due to its robust construction, making it a favored choice for high-traffic areas.

**Tip 1:** Evaluate the lifecycle cost of various grating types. While some alternatives may have lower initial costs, their longevity and associated maintenance can significantly impact long-term budgets.

In contrast to fiberglass or aluminum grating, mill finish steel grating often shows better performance under heavy loads and adverse conditions. This makes it an ideal option for projects where strength and durability are critical. According to industry reports, mill finish steel can perform effectively under weights exceeding 1,000 pounds per square foot, ensuring stability in demanding environments.

**Tip 2:** Ensure proper installation to maximize the lifespan of your mill finish steel grating. Investing in professional installation can prevent future repair costs and enhance overall project efficiency.