Low Carbon Steel Grating is becoming increasingly popular in the construction industry. Its strength and lightweight properties make it a favored choice for various applications. As builders seek sustainable options, low carbon steel grating stands out due to its durability and cost-effectiveness.

Choosing the right type of low carbon steel grating can be challenging. There are several styles available, each with unique characteristics. Some designs offer better support, while others excel in aesthetics. It's essential to consider the project requirements carefully. Not every option fits every scenario perfectly. Missteps can lead to inefficiencies and increased costs.

Even with its advantages, low carbon steel grating comes with its own set of concerns. Corrosion resistance and weight limits are critical factors. Often, there are trade-offs that investors must weigh. The balance between performance and cost is not always straightforward. Making informed choices can significantly impact construction outcomes.

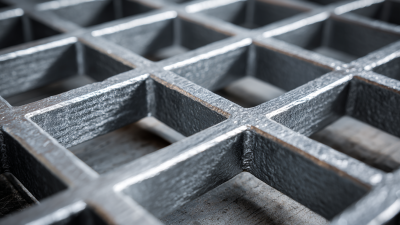

Low carbon steel grating is a versatile material used widely in construction. It provides durability and strength. This grating type is made from steel with a low carbon content, making it less prone to corrosion. Such properties enhance its lifespan and reduce maintenance costs. Additionally, it offers excellent load-bearing capabilities. Many construction projects rely on this material for walkways and platforms.

One of the main benefits of low carbon steel grating is its lightweight nature. It is easy to transport and install. This efficiency saves time on-site. Moreover, low carbon steel can be recycled, contributing to sustainability efforts. The material allows for design flexibility. Builders can create custom sizes and shapes to fit specific needs. However, it is essential to monitor its exposure to harsh chemicals. Ignoring this can lead to potential degradation. Using proper coatings can help extend its longevity further.

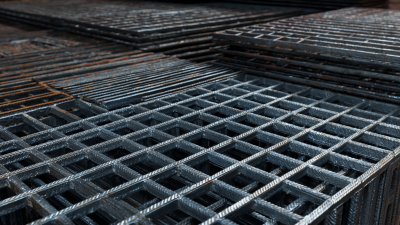

Low carbon steel grating is commonly used in construction due to its durability and strength. It is an ideal choice for flooring, walkways, and platforms. The most prevalent types include welded, rivet, molded, and press-locked grating. These variations serve distinct purposes and applications.

Welded grating is known for its robust construction. It provides excellent load-bearing capabilities. Typically, it consists of carbon steel bars welded crosswise. This type of grating is popular for heavy-duty applications. It can support up to 1,500 pounds per square foot. Notably, riveted grating offers similar benefits but is easier to manufacture in large sizes.

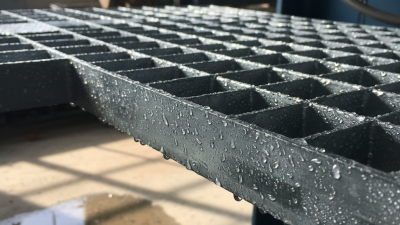

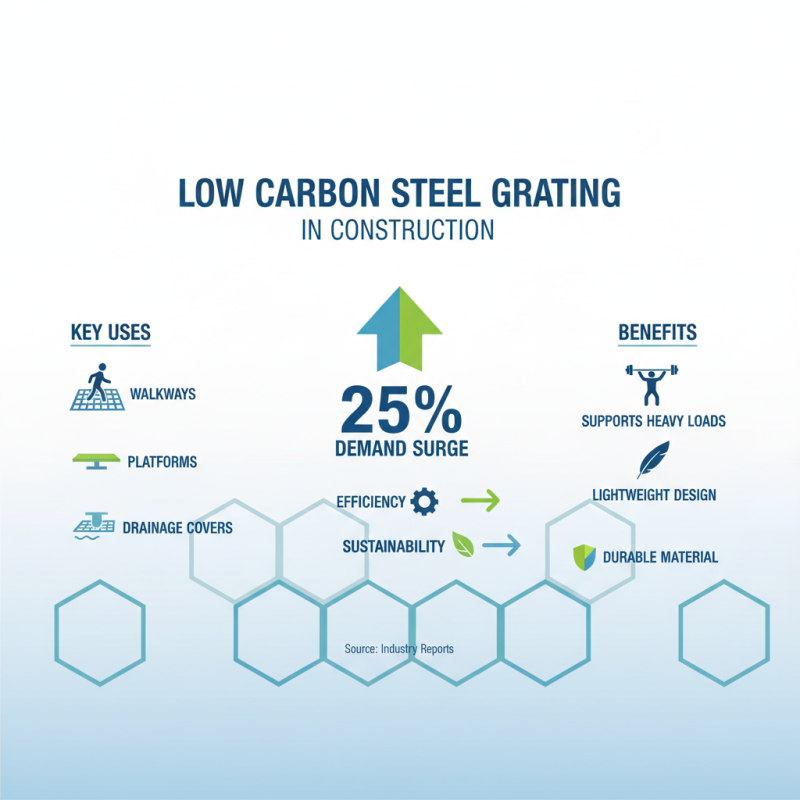

Molded grating, on the other hand, is crafted by combining fibers and resins with steel. This method enhances resistance to corrosion. It is ideal for environments exposed to chemicals. Press-locked grating is another option, characterized by its interlocking bars. It requires no welding and is lighter. A recent industry report suggested that the use of these types of grating has increased by 25% in various building projects over the past five years.

Despite the advantages, choosing the right type requires careful consideration. Environmental factors and load requirements must be assessed. Each grating type presents unique pros and cons that may affect the overall project outcome. Understanding these details is crucial in making well-informed decisions.

Low carbon steel grating is essential in construction. It is durable, cost-effective, and versatile. Various designs of low carbon steel grating serve different purposes. A recent industry report noted that welded steel grating accounts for approximately 45% of all steel grating types used in construction. Its robust structure, suitable for heavy load-bearing applications, makes it popular.

Another type is the molded grating, which brings advantages like corrosion resistance. Only 30% of projects use this option. Its lightweight nature makes it easier for installation. However, it may not support the same weight as welded types. A comparative analysis reveals that some choose expanded metal grating for its aesthetic appeal. This accounts for about 15% of usage and offers a unique textured look.

But not every choice comes without flaws. For instance, while bar grating is strong, it can be less comfortable underfoot. Reports suggest that slip resistance could be a concern in wet conditions. A significant number of constructions may be compromised by these small details. The right design should balance strength, cost, and safety for effective construction use.

| Grating Type | Load Capacity (lbs) | Aperture Size (inches) | Weight (lbs/ft²) | Durability (Years) |

|---|---|---|---|---|

| Steel Bar Grating | 1000 | 1 x 1 | 3.5 | 25 |

| Expanded Metal Grating | 750 | 0.5 x 1 | 2.0 | 20 |

| Welded Wire Grating | 1200 | 2 x 2 | 4.0 | 30 |

| Frp Grating | 600 | 1 x 1 | 1.5 | 15 |

| Pressure Locked Grating | 900 | 1.5 x 3 | 2.8 | 25 |

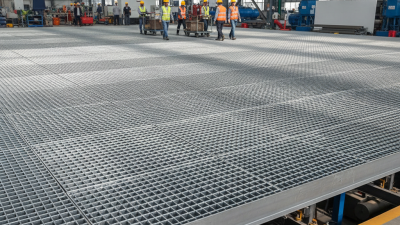

Low carbon steel grating serves various purposes in the construction industry. It supports heavy loads while offering a lightweight design. For instance, it is ideal for walkways, platforms, and drainage covers. According to industry reports, the demand for durable materials has surged by 25% in recent years. This trend highlights a shift toward efficiency and sustainability in construction.

One common application is in industrial facilities. Here, low carbon steel grating ensures safe access to machinery. Maintenance workers rely on sturdy platforms to perform their tasks. Market data suggest that nearly 40% of construction projects now utilize this material for flooring and shelving. Yet, some projects still overlook the importance of proper material selection. Inadequate choices can compromise safety.

Another vital use is pedestrian walkways in urban environments. These structures facilitate foot traffic while maintaining visibility below. Reports indicate that using low carbon steel grating can reduce slip accidents by 30%. Still, not every project measures up to these standards. Some fail to consider drainage needs, leading to potential flooding. Improved planning and assessment are crucial in these scenarios.

Low carbon steel grating is a popular choice in construction due to its durability and cost-effectiveness. However, maintenance is key to ensuring its longevity. Regular inspections can reveal rust or damage. Immediate attention is necessary to prevent further deterioration. Corrosion can be a significant issue. A protective coating can help, but it requires periodic reapplication.

Cleaning is essential for low carbon steel grating. Accumulated debris can trap moisture, leading to rust formation. Regular washing with water can mitigate this risk. Keep an eye on the drainage systems too. Blocked drains can cause standing water to damage the grating. Sometimes, repairs might be overlooked, leading to bigger problems later.

It can be easy to underestimate the wear and tear on grating. Daily traffic and weather can take a toll. Establishing a routine maintenance schedule could be beneficial. Observing changes in the appearance of the grating may signal a need for more thorough inspections. Investing time in upkeep can result in extended service life for low carbon steel grating solutions.