The importance of safety and performance in industrial settings cannot be overstated, particularly when it comes to flooring solutions such as Black Serrated Grating. According to industry reports, nearly 60% of workplace accidents are attributed to slips and falls, highlighting the need for effective safety measures. Traditional Black Serrated Grating, while widely used for its slip-resistant properties, has limitations that can impact overall performance and safety in demanding environments. Innovative alternatives, such as lightweight composite materials and advanced coatings, are emerging as viable options that not only enhance grip but also improve durability and maintenance efficiency. These alternatives offer the potential to reduce workplace incidents by up to 30%, making it imperative for businesses to explore enhanced flooring solutions that exceed the capabilities of conventional Black Serrated Grating. As industries evolve and prioritize safety, understanding the benefits of new materials becomes crucial for effective risk management and operational excellence.

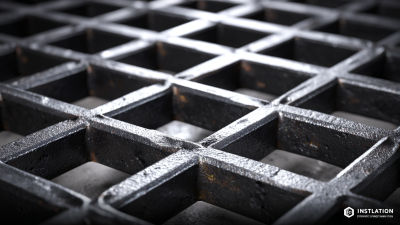

Traditional black serrated grating has long been favored for its slip-resistant properties and structural integrity. However, its limitations begin to emerge in safety applications, particularly in environments subjected to heavy foot traffic, spills, and adverse weather conditions. The inherent design can lead to a false sense of security, as accumulated grime and debris can compromise its surface traction. Furthermore, the dark color can make it challenging to spot hazards, such as cracks or water pooling, especially in dimly lit areas.

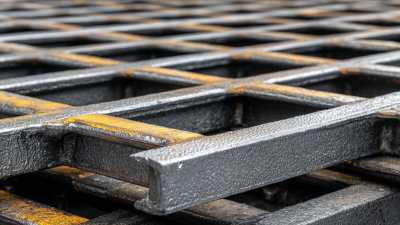

To enhance safety and performance, consider integrating brightly colored or luminescent alternatives to black serrated grating. These options not only maintain the slip-resistant properties of traditional materials but also provide improved visibility in low-light environments. Additionally, choosing materials that are more resistant to corrosive elements can reduce wear and prolong the grating’s life, addressing the issue of maintenance in high-use areas.

Tips for selecting optimal grating for safety applications include evaluating the specific environmental conditions where the grating will be used and considering the material’s wear resistance and ease of cleaning. It's also beneficial to engage with manufacturers who offer customizable grating solutions to address unique safety concerns tailored to your facility's needs.

In recent years, the construction and industrial sectors have seen a significant shift towards safer and more innovative materials, particularly regarding grating solutions. Traditional black serrated grating has long been favored for its slip-resistant properties; however, its limitations in terms of durability and environmental impact have prompted manufacturers to seek alternatives. According to a report by the American National Standards Institute (ANSI), nearly 30% of workplace injuries are attributed to slips and falls, emphasizing the need for enhanced safety features in flooring materials.

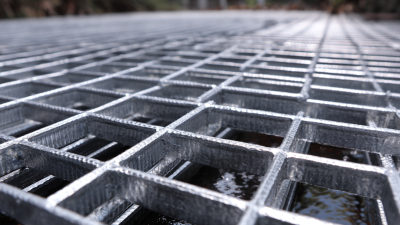

In recent years, the demand for advanced grating technologies has led to significant innovations that enhance both safety and performance in various industrial applications. Traditional black serrated grating, while effective, has its limitations in terms of slip resistance and durability. The introduction of new materials, such as fiberglass and composite polymers, offers improved strength and a lighter weight, allowing for easier installation and maintenance. These modern alternatives are designed to withstand harsh environmental conditions, making them ideal for outdoor settings.

Moreover, the adoption of advanced surface textures and coatings plays a critical role in performance enhancement. These features not only provide superior slip resistance, which is paramount in high-traffic areas, but they also contribute to reduced wear and tear over time. Additionally, integrating customizable colors and patterns into these grating systems enhances their aesthetic appeal while maintaining functionality. As industries continue to prioritize safety and efficiency, exploring these innovative grating technologies presents a promising solution for modern infrastructure needs.

| Feature | Description | Benefits | Application Areas |

|---|---|---|---|

| Enhanced Slip Resistance | Surface texture designed to minimize slipping | Improves safety in wet or oily conditions | Walkways, industrial floors, and staircases |

| Corrosion Resistance | Materials that withstand harsh environments | Longer lifespan and reduced maintenance costs | Wastewater treatment, chemical processing |

| Lightweight but Strong | Innovative materials that maintain structural integrity while reducing weight | Easier installation and lower transportation costs | Bridge applications and elevated walkways |

| Customization Options | Tailored sizes, colors, and load ratings | Meets specific needs of various industries | Manufacturing, construction, and public spaces |

| Eco-Friendly Materials | Sustainable materials that reduce environmental impact | Supports green building initiatives | Commercial buildings and urban development |

In recent years, industries have increasingly recognized the need for safer, more efficient alternatives to traditional black serrated grating. Real-world case studies illustrate the successful implementation of alternative grating solutions that enhance safety and performance. One notable example comes from a manufacturing facility that switched to fiberglass grating. This shift not only reduced slip hazards but also improved visibility due to its lighter color and non-corrosive properties. Workers reported feeling more secure while navigating the spaces, which ultimately contributed to a decrease in workplace incidents.

Another compelling case is seen in a municipal project where aluminum grating was used in place of traditional options. This transition provided significant weight savings and easier installation, translating to reduced labor costs. Importantly, the aluminum grating was also designed with a unique surface texture that enhanced traction, further bolstering safety for pedestrians and cyclists in public areas. These examples underscore how innovative alternative gratings not only meet but exceed safety standards while optimizing performance across various sectors.

The evolution of grating solutions is increasingly aligning with global trends towards safety and performance, particularly in the context of sustainability and advanced technologies. As reported by WIPO, the transportation sector is seeing a rapid growth in innovations aimed at environmentally friendly technologies, which is essential as industries look to reduce their carbon footprints. Key developments include the integration of composite materials known for their high performance and green properties. By 2025, the composite materials market in China is expected to expand significantly, driven by increasing demand for sustainable solutions across various applications, indicating a vital shift in how materials are conceived within safety infrastructures.

Moreover, the continuous push for digitization is reshaping the landscape of safety solutions. Gartner's recent analysis highlights the critical role of digital sovereignty and AI-driven technologies in transforming operational safety approaches. As grating systems become more sophisticated, incorporating AI and machine learning, they promise enhanced monitoring and real-time response capabilities. This paradigmatic shift is not only about compliance with safety regulations but also about integrating cutting-edge technology that enhances overall performance, opening new avenues for innovation in safety solutions across various sectors.