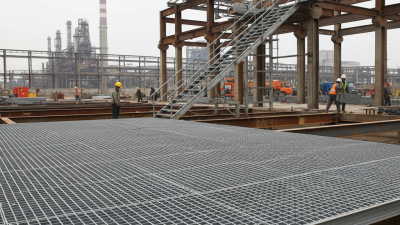

The weight of galvanized steel grating plays a crucial role in various construction projects. Understanding "Galvanized Steel Grating Weight" helps in many ways. It influences the ease of handling and installation. Heavy grating can complicate logistics while lighter options may be easier to manage.

In specific applications, weight impacts load-bearing capacity. Projects requiring high strength may need heavier options. Yet, lighter grating can reduce overall project load. This balance is not always straightforward. Engineers must consider all factors carefully.

Moreover, the cost implications are significant. Heavier materials may lead to higher shipping costs. It's essential to weigh benefits against costs. Not every project will require the heaviest grating available. Reflecting on these aspects can lead to better decisions in steel grating selection.

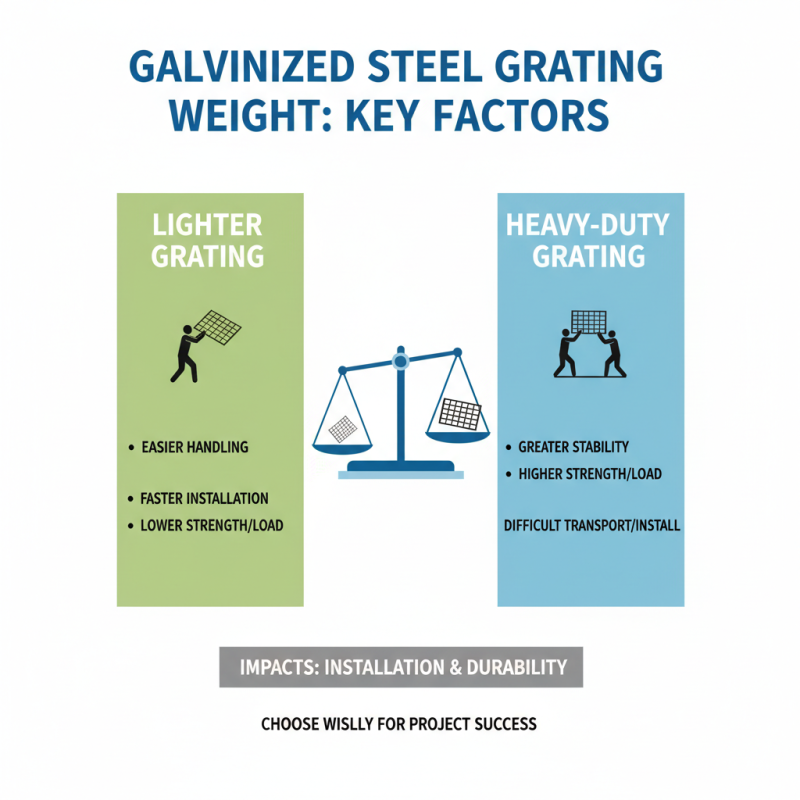

Understanding the weight of galvanized steel grating is essential for any construction project. The weight affects installation methods and overall durability. Lighter grating may be easier to handle but can compromise strength. Heavy-duty options provide better stability but are harder to transport.

When calculating load capacity, knowing the weight of the grating is crucial. A proper weight ensures that structures will support intended loads. Misjudging this may lead to costly adjustments later on. Projects can face unexpected delays if the wrong materials are chosen. In some cases, they may even require expensive modifications.

Choosing the right weight involves more than mere calculations. It requires thoughtful consideration of material characteristics and environmental factors. Different settings, like coastal areas, demand more resistance to corrosion. Reflecting on these aspects can prevent future issues. The right balance between weight and functionality is key to successful outcomes.

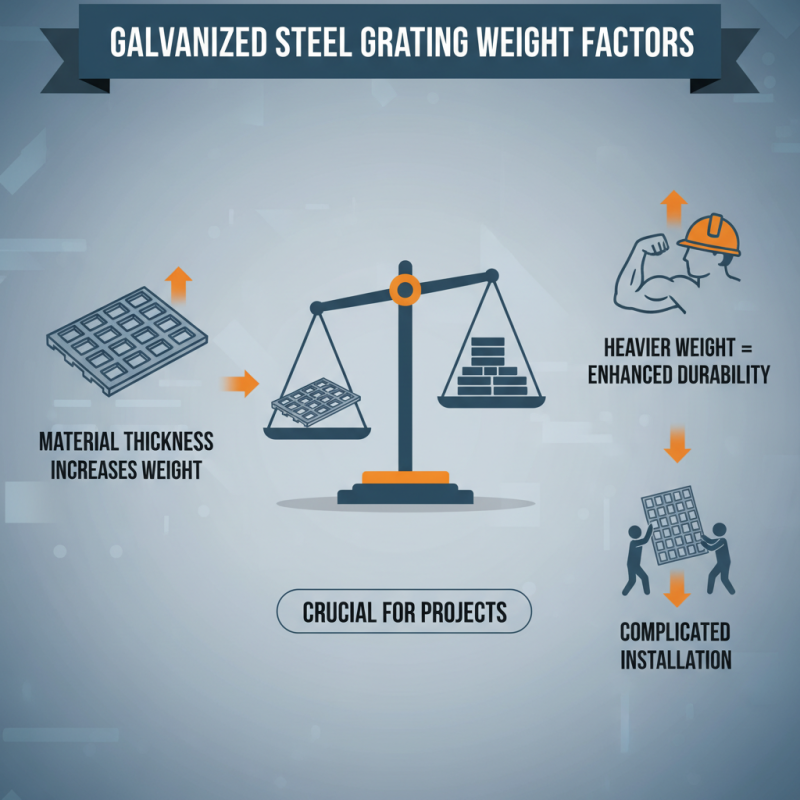

The weight of galvanized steel grating is a crucial aspect for many construction projects. Various factors influence this weight. Material thickness is a primary consideration, as thicker grating contributes significantly to overall weight. A heavy weight can enhance durability but may complicate installation.

Another factor is the design of the grating. Different patterns can lead to variance in weight. For example, a thicker load-bearing grating will weigh more than a lightweight option. This choice affects not only structural integrity but also transportation and handling.

Understanding the weight distribution also matters. Proper weight distribution can alleviate stress on supporting structures. However, heavier grating may require additional supports, possibly resulting in higher costs. It's important to reflect on how these choices impact both structural performance and budget constraints. Balancing weight and functionality is a common challenge.

When planning a construction project, the weight of galvanized steel grating plays a critical role. It impacts structural integrity and safety. Heavier grating may offer better durability, but it also requires stronger support systems. If the underlying structure isn't up to par, it can lead to serious issues.

Using lighter grating can reduce overall project weight. This might ease installation and lower costs. However, the compromise may involve reduced support, which can affect safety. It’s important to find the right balance between weight and strength.

Each project is unique. The choice of grating must consider specific environmental factors. For example, grating used in wet areas needs better drainage. Failure to evaluate these factors can lead to unexpected challenges. Prioritizing weight without assessing its impact on safety could be a costly mistake.

When choosing galvanized steel grating for projects, weight plays a crucial role. Heavier grating might seem more durable, but can lead to higher transport costs. Lighter options may save money, but durability needs to be considered. Finding a balance is essential.

Cost considerations extend beyond material choice. Installation costs increase with heavier grating. Labor may have to adjust equipment or techniques. This can inflate the overall project budget. Sometimes, lighter materials can result in savings elsewhere. They may reduce handling challenges and speed up installation.

Discussing weight can feel tedious, yet it’s vital. A well-planned project accounts for every factor. Teams must assess their unique needs. Overlooking weight could lead to unforeseen issues. The end goal is efficiency with cost-effectiveness.

| Project Type | Grating Weight (lbs/sq ft) | Material Cost ($/sq ft) | Total Weight (lbs) | Estimated Delivery Cost ($) |

|---|---|---|---|---|

| Industrial Flooring | 5.0 | 12.00 | 1500 | 200 |

| Walkway Grating | 3.5 | 10.00 | 850 | 150 |

| Roof Drainage | 4.0 | 11.50 | 1200 | 180 |

| Oceanic Platforms | 6.0 | 15.00 | 1800 | 250 |

| Heavy Machinery Support | 7.5 | 20.00 | 2250 | 300 |

When considering galvanized steel grating for a project, weight plays a crucial role. For instance, grating that is too light might not support heavy loads. On the other hand, grating that is excessively heavy can increase transportation and installation costs. Industry reports suggest that the average weight of galvanized steel grating is between 10 and 20 pounds per square foot. This data highlights the need to match the grating weight with project demands.

Selecting the right weight involves analyzing project requirements. For pedestrian walkways, lighter grating is often sufficient. However, for industrial applications, a heavier option may be necessary. Consider the load capacity specifications; they vary widely based on the steel's gauge and spacing. Some projects overlook these details, leading to potential structural failures or increased maintenance costs. It's vital to evaluate the environment as well, as different settings can affect how weight impacts performance.

The choice of galvanized steel grating weight can also influence corrosion resistance. Heavier grating typically has a thicker coating, which may enhance durability. Yet, this can add to installation challenges. Always reflect on the necessary balance between weight and functionality. Each project has unique demands; failing to address these could lead to costly mistakes down the line.