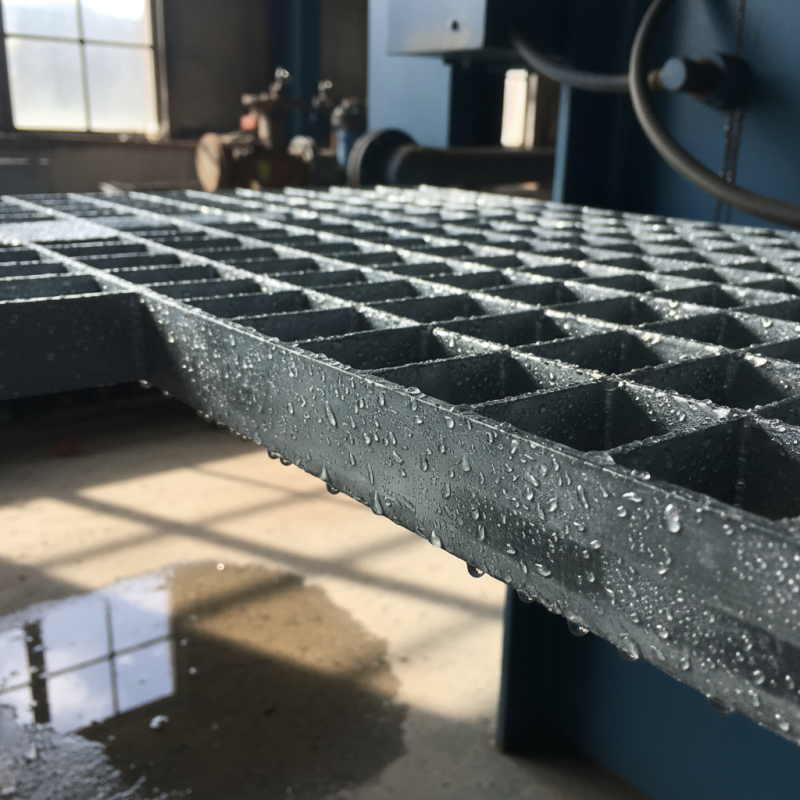

Hot Dipped Steel Grating is gaining popularity in various industries due to its durability and resistance to corrosion. According to John Smith, a leading expert in steel fabrication, "The benefits of Hot Dipped Steel Grating are profound, especially in harsh environments." This type of grating is made by dipping steel into molten zinc, creating a robust barrier against the elements.

Many industries, such as construction and manufacturing, rely on Hot Dipped Steel Grating for safety and efficiency. Its open design allows for excellent drainage and ventilation. However, it’s crucial to consider both its advantages and potential drawbacks. For example, while it is long-lasting, the initial cost can be higher than alternative materials. Some users may also find the surface texture can be slippery when wet.

Understanding Hot Dipped Steel Grating’s benefits and challenges can help businesses make informed decisions. It is not just about selecting the right material; it’s about understanding its application in real-world scenarios. As industries evolve, so too will the methods and materials they rely on for safety and sustainability.

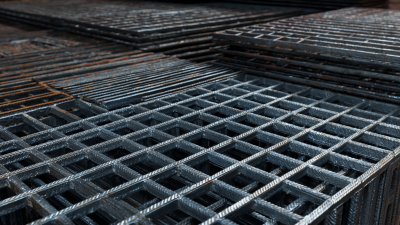

Hot dipped steel grating is a widely used product in various industrial applications. This form of grating is made from steel bars that undergo a hot dip galvanization process. This process involves dipping the steel in molten zinc to create a robust protective coating. According to a recent industry report, galvanized steel has a lifespan of over 50 years when properly maintained. This longevity makes it an economical choice for many businesses.

The use of hot dipped steel grating offers several advantages. Its corrosion resistance is notable, which is crucial in harsh environments. For example, in wastewater treatment plants, corrosion can drastically reduce the lifespan of materials. Hot dipped grating counters this issue, ensuring durability. Furthermore, it supports heavy loads effectively. The grating can handle up to 2,500 pounds per square foot. This is especially beneficial in industrial settings where heavy machinery is commonplace.

However, hot dipped steel grating is not without challenges. The initial cost may be higher than plain steel options. Over time, the investment is justified through reduced maintenance needs. Another concern is the potential for inadequate adhesion during the coating process. If not applied correctly, the grating can experience early wear. It's essential for manufacturers to adhere to quality standards to avoid these pitfalls.

| Property | Description |

|---|---|

| Material | Steel coated with a layer of zinc through the hot-dip galvanizing process. |

| Corrosion Resistance | Highly resistant to rust and corrosion, extending the lifespan of the grating. |

| Load Capacity | Designed to support heavy loads, making it suitable for industrial applications. |

| Applications | Commonly used in walkways, stair treads, platforms, and industrial flooring. |

| Benefits | Provides safety, easy drainage, durability, and low maintenance. |

| Aesthetic Appeal | Available in various designs and finishes to suit different architectural styles. |

Hot dipped steel grating is known for its

durability and strength. The manufacturing process is crucial in achieving these qualities. First, steel bars

are carefully selected. They must meet strict standards for size and quality. These bars are then cut to

specific lengths.

Next, they are arranged in a grid pattern. At this stage, attention to detail is vital. Ensuring that spaces

between the bars are uniform can be challenging. Once positioned, the bars go through welding. This process

can create weak points if not done correctly. After welding, the grating is cleaned to remove any impurities.

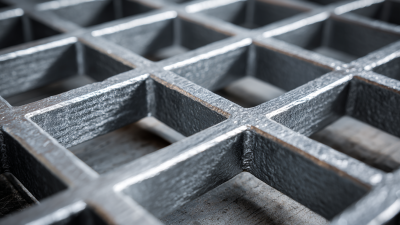

The hot-dipping process follows, where the grating

is submerged in molten zinc. This step provides excellent corrosion resistance. However, not all coatings are

equal. Variability in temperature can affect durability. After cooling, the product undergoes inspection. Each

piece must meet quality standards. If flaws are detected, they require further action. This entire process

emphasizes precision and dedication to quality.

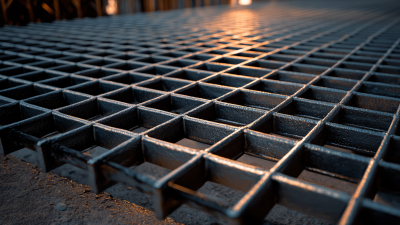

Hot dipped steel grating is made by coating steel with molten zinc. This process ensures durability and resistance to corrosion. The grating features an open design that allows for water drainage and airflow. A significant aspect of hot dipped steel grating is its strength. It can support heavy loads and withstand harsh environments, making it suitable for various applications.

Key specifications include standard sizes and load capacities. The bar spacing in the grating can be adjusted for specific needs. Typically, the spacing ranges from 1 inch to 4 inches. The thickness of the bars also varies, often between 0.25 inches and 0.5 inches. Buyers should consider these details to ensure the appropriate choice for their projects.

While hot dipped steel grating offers many benefits, proper installation is crucial. Incorrect installation can lead to premature wear. Users should reflect on maintenance practices to extend the grating's lifespan. A balance between strength and weight is essential for optimal performance.

Hot dipped steel grating offers significant benefits in construction. Its durability is a key advantage. According to industry reports, this type of grating can last up to 50 years with minimal maintenance. Its corrosion resistance comes from a zinc coating applied through hot-dipping. This process ensures that the grating can withstand harsh weather conditions. It is particularly effective in coastal areas, where salt exposure can accelerate corrosion.

Additionally, hot dipped steel grating is cost-effective. The initial investment is often higher than other materials. However, the long lifespan reduces replacement and maintenance costs. A study indicated that these grates can save more than 30% in life-cycle costs compared to untreated options. This makes them ideal for high-traffic areas, such as industrial facilities and pedestrian walkways.

One challenge with hot dipped steel grating is weight. It can be heavier than alternatives, making installation more complex. Some projects may require additional manpower or equipment. This factor can lead to increased labor costs. Furthermore, the aesthetics of the grating may not appeal to everyone, particularly in architectural applications. These aspects require careful consideration in project planning.

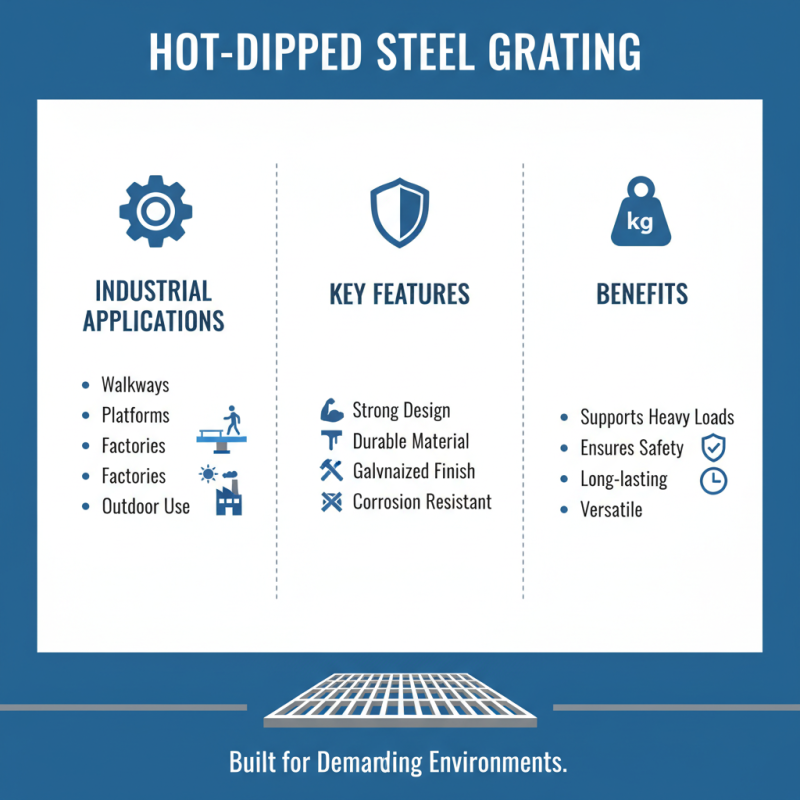

Hot dipped steel grating is widely used across various industries. Its strong, durable design makes it suitable for demanding applications. This type of grating features a galvanized finish, which enhances its corrosion resistance. As a result, it is ideal for outdoor use. Factories often rely on this material for walkways and platforms. It supports heavy loads while ensuring safety.

In the construction industry, hot dipped steel grating serves as a flooring solution. It allows for better drainage and airflow. This is crucial in preventing water accumulation. In waste management facilities, the grating can withstand harsh chemicals. It offers longevity in tough conditions. Transportation sectors also benefit from this grating. It is used in tram and railway systems, providing stability and strength.

Despite its many advantages, challenges exist. Some users may struggle with installation. Proper alignment and support are crucial for performance. If misaligned, safety risks can arise. Regular inspections are necessary to ensure integrity. Overall, while hot dipped steel grating is a reliable choice, it requires careful handling and maintenance.