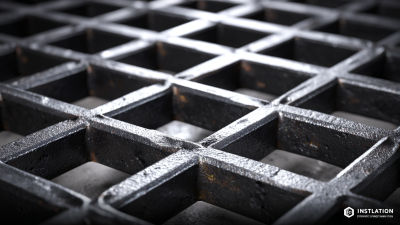

In recent years, the demand for Plain Steel Grating has surged significantly, driven by its versatile applications across various industries, including construction, manufacturing, and infrastructure. According to a report by MarketsandMarkets, the global market for steel grating is expected to reach USD 5.9 billion by 2025, growing at a CAGR of 5.9% from 2020. This growth can be attributed to the increasing need for durable and cost-effective materials that offer both strength and lightweight properties. As innovations emerge, Plain Steel Grating is evolving beyond traditional uses, integrating advanced design techniques and coatings that enhance durability and corrosion resistance. This ultimate guide explores the latest trends and technological advancements shaping the future of Plain Steel Grating, positioning it as an indispensable component in modern industrial applications.

The future of plain steel grating is being reshaped by innovative materials and coatings that significantly enhance durability and functionality. Recent advancements in high-performance materials are driving a wave of change in construction practices. For instance, the introduction of nanomaterial-based coatings offers exceptional corrosion protection, particularly in harsh environments. These smart coatings not only improve the lifespan of steel grating but also contribute to sustainable construction by minimizing maintenance and replacement needs.

In addition to coatings, the emergence of advanced manufacturing techniques, such as 3D printing, is transforming traditional steel applications. By enabling customized designs and more complex geometries, these technologies allow for optimized performance and resource efficiency in creating plain steel grates. As industries increasingly prioritize sustainability, the integration of innovative materials in steel production reflects a broader trend toward reducing environmental impact while enhancing structural resilience, ultimately positioning plain steel grating for a robust future in modern construction.

Sustainable practices are increasingly becoming a focal point in the manufacturing of plain steel grating, driving innovations that not only enhance efficiency but also minimize environmental impact. The shift towards eco-friendly materials and processes is reshaping the landscape of the industry. Manufacturers are exploring the integration of recycled steel, which significantly reduces energy consumption and resource depletion. By sourcing materials sustainably, companies can meet the growing demand for environmentally responsible products while maintaining high quality and durability.

Sustainable practices are increasingly becoming a focal point in the manufacturing of plain steel grating, driving innovations that not only enhance efficiency but also minimize environmental impact. The shift towards eco-friendly materials and processes is reshaping the landscape of the industry. Manufacturers are exploring the integration of recycled steel, which significantly reduces energy consumption and resource depletion. By sourcing materials sustainably, companies can meet the growing demand for environmentally responsible products while maintaining high quality and durability.

In addition to material innovations, the adoption of energy-efficient production techniques plays a crucial role in the sustainability of plain steel grating manufacturing. Technologies like advanced welding methods and automated machinery not only streamline operations but also lower emissions. Furthermore, manufacturers are investing in renewable energy sources, such as solar and wind, to power production facilities. This commitment to operating sustainably is not only beneficial for the environment but also aligns with the values of an increasingly eco-conscious consumer base, paving the way for a more responsible industry.

In recent years, the plain steel grating industry has witnessed significant technological advancements that enhance its applications across various sectors. Innovations such as the development of new welding techniques and improved manufacturing processes have not only increased the strength and durability of steel grating but also reduced production costs by up to 15%, according to the Steel Grating Association. These advancements enable manufacturers to produce high-quality products that meet diverse industrial requirements, from construction to heavy-duty machinery.

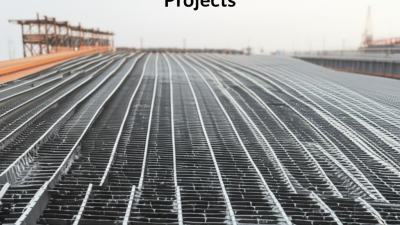

Moreover, the integration of cutting-edge technologies, like CNC machining and robotics, has revolutionized the customization capabilities of plain steel grating. Customization is now more efficient, allowing for quick adaptations to specific project needs, thereby reducing lead times by approximately 20%. Reports indicate that the global market for steel grating is expected to grow at a compound annual growth rate (CAGR) of 4.7% over the next five years, underscoring the importance of these innovations in maintaining competitiveness. As industry players continue to invest in research and development, we can expect even more transformative changes that will redefine the future landscape of plain steel grating applications.

In recent years, the plain steel grating industry has witnessed significant advancements driven by customization trends. As manufacturers strive to meet diverse client demands, innovative design techniques have emerged, allowing for greater flexibility in production. Customization not only enhances aesthetic appeal but also optimizes functionality for various applications, from construction to infrastructure. According to a recent market analysis, the global steel grating market is expected to grow steadily, reflecting an increasing demand for tailored solutions that can accommodate specific load-bearing and environmental requirements.

Furthermore, the integration of technology in the design process has revolutionized how steel gratings are developed. Digital modeling and simulation tools enable engineers to create bespoke designs efficiently, reducing time to market. Industry reports highlight that companies that adopt such innovations can anticipate a growth rate of around 9.14% in the coming years, aligning with broader trends seen across various manufacturing sectors. As customization becomes a key driver in the plain steel grating market, the ability to deliver unique, high-quality solutions will define competitive advantage in the evolving landscape.

The plain steel grating industry is poised for significant growth, driven by various emerging trends and market opportunities. According to a recent Market Research Future report, the global steel grating market is expected to expand at a compound annual growth rate (CAGR) of over 6% from 2021 to 2027. This growth is fueled by the increasing demand for lightweight yet durable materials in infrastructure, construction, and industrial applications.

One of the prominent trends reshaping the plain steel grating landscape is the move towards sustainable materials and manufacturing processes. A report by Grand View Research indicates that the demand for eco-friendly construction materials will lead to innovations in the production of steel grating systems. Companies are now investing in research and development to create products that not only meet safety and performance standards but also reduce environmental impact. Additionally, as urbanization accelerates, the need for effective drainage and ventilation systems in urban infrastructure projects has sparked investment in plain steel grating solutions, creating ample opportunities for manufacturers to diversify and enhance their product offerings.