As the industrial landscape continues to evolve, the significance of galvanized steel grating in various applications has become increasingly prominent. According to a recent report by MarketsandMarkets, the global market for steel grating is projected to reach USD 3.42 billion by 2025, driven by its versatility, durability, and cost-effectiveness. Galvanized steel grating, in particular, has garnered attention for its corrosion-resistant properties which enhance safety and longevity in industrial settings. This innovative material is not only essential for construction, but also plays a vital role in sectors such as petrochemical, manufacturing, and transportation. With advancements in manufacturing technologies and growing environmental regulations, the future of galvanized steel grating will be characterized by enhanced performance metrics and broader application horizons, positioning it as a critical component in modern industrial frameworks.

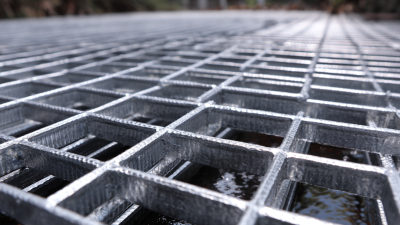

The evolution of galvanized steel grating has been a pivotal element in modern industrial design, marked by continuous innovations that enhance both functionality and aesthetics. Initially, galvanized steel grating served primarily practical purposes, such as providing ventilation and access in industrial settings. However, recent advancements have introduced a range of designs that offer greater resilience, corrosion resistance, and safety features, making them suitable for more diverse applications, from pedestrian walkways to heavy machinery platforms.

As industries increasingly prioritize sustainability and efficiency, galvanized steel grating has adapted to meet these demands. Modern production techniques have led to lighter, stronger, and more versatile grating options, incorporating eco-friendly materials and finishes. This transformation reflects a broader trend in industrial design, where the focus is not only on utility but also on creating spaces that are visually appealing and environmentally responsible. The integration of innovative designs continues to pave the way for galvanized steel grating to play a crucial role in shaping the future of industrial infrastructure.

Galvanized steel grating has become an integral component in modern industrial applications due to its impressive durability and corrosion resistance. According to a recent report by MarketsandMarkets, the global demand for galvanized steel is expected to reach 40 million metric tons by 2026, underscoring its importance in sectors such as construction, manufacturing, and energy. The galvanized coating enhances the lifespan of the steel, reducing maintenance costs significantly—reports indicate a lifecycle increase of 50% compared to non-galvanized options.

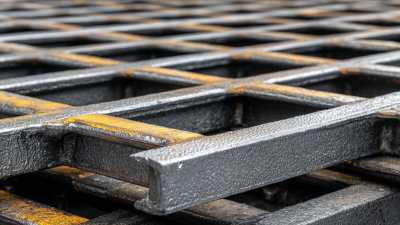

When implementing galvanized steel grating in your projects, consider the weight load requirements. The American Institute of Steel Construction (AISC) recommends specific load capacities that grating must meet to ensure safety and longevity in industrial settings.

**Tips**: Always assess the environmental conditions of your project. Areas exposed to harsh chemicals or extreme weather will benefit from higher-grade galvanized coatings. Additionally, consult with suppliers to optimize the design features, such as bar spacing and thickness, tailored to your specific application to maximize efficiency and safety.

| Application Area | Key Benefits | Durability (Years) | Cost Effectiveness (per sq ft) |

|---|---|---|---|

| Manufacturing Plants | High Load Capacity, Corrosion Resistance | 20 | $10 |

| Transportation Facilities | Lightweight, Easy Installation | 15 | $9 |

| Commercial Buildings | Aesthetic Appeal, Safety Features | 25 | $12 |

| Stadiums and Arenas | Versatile Design, Non-slip Surface | 30 | $14 |

| Waste Water Treatment | Chemical Resistance, Low Maintenance | 18 | $11 |

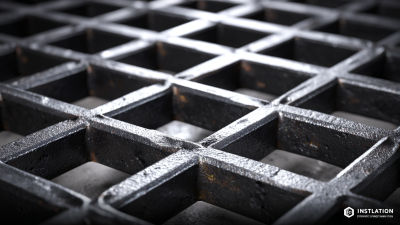

When choosing the right galvanized steel grating for modern industrial applications, several key parameters should be prioritized to ensure optimal performance. First and foremost, the load capacity of the grating should be assessed against the expected traffic and environmental conditions. Different applications, such as pedestrian walkways or heavy machinery platforms, require varying strength levels. Additionally, the spacing between the bars is crucial; closer spacing can offer increased safety but may also impact drainage and weight.

Another important factor to consider is the surface finish and corrosion resistance of the galvanized steel. High-quality galvanization can significantly extend the lifespan of the grating, particularly in corrosive environments. Compatibility with existing structures also plays a critical role, as the chosen grating must seamlessly integrate into the current setup without requiring excessive modifications. By carefully analyzing these aspects, industries can select the most suitable galvanized steel grating that meets safety and durability standards while enhancing operational efficiency.

The rise of sustainable manufacturing practices has positioned galvanized steel grating as a pivotal element in modern industrial applications. This innovative material not only offers durability and strength but also aligns seamlessly with the growing emphasis on eco-friendly production methods. By its very nature, galvanized steel is resistant to corrosion, extending its lifespan and reducing the need for replacements. This longevity contributes to lower material consumption over time, highlighting its role in a circular economy.

Furthermore, advancements in galvanization techniques have made it possible to enhance the environmental performance of steel grating. Manufacturers are increasingly adopting processes that minimize waste and energy consumption during production. The integration of recycled materials into the grating composition is becoming more commonplace, further reducing the environmental footprint. In addition, companies are focusing on creating grating systems that promote efficient drainage and airflow, essential characteristics in designing sustainable industrial spaces. As industries continue to prioritize environmental responsibility, the future of galvanized steel grating looks promising, firmly establishing it as a cornerstone of sustainable manufacturing practices.

Galvanized steel grating serves as a vital component in various industrial applications due to its durability and corrosion resistance. However, recent tragic incidents, such as the death of six students at a university due to a grid panel failure, have reignited discussions about safety considerations in workplaces utilizing this material. The unfortunate event highlights the critical importance of proper maintenance and inspection of grating systems to prevent similar accidents.

According to industry reports, approximately 40% of workplace accidents result from inadequate safety protocols involving flooring and grating systems. The American National Standards Institute (ANSI) outlines specific guidelines to ensure the structural integrity and safety of steel gratings in industrial environments. Regular inspections and adherence to load-bearing specifications can mitigate risks significantly. In the case of galvanized steel grating, which sees widespread use in environments prone to spills and heavy loads, such precautions are essential to safeguard employees and prevent catastrophic failures.

Investing in high-quality galvanized steel grating that meets established safety standards can reduce incidents related to equipment failure. With the continual evolution of industrial applications, it is paramount to prioritize safety measures alongside advancements in material technology. Implementing comprehensive training programs for workers and regular audits of grating installations can further strengthen safety in industrial settings.