The industrial sector is witnessing a transformative evolution with the advent of

innovative materials and designs, none more significant than

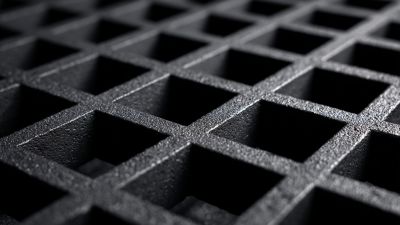

Black Plain Grating. As industries increasingly prioritize

safety, efficiency, and sustainability, the

demand for high-performance structural components has risen dramatically. According to a

recent report by Industry Research, the global grating market is projected to reach

$4.9 billion by 2027, growing at a CAGR of 5.2%.

This trend highlights the vital role that advancements in materials, such as Black Plain Grating,

play in improving load-bearing capabilities while minimizing maintenance costs. By incorporating

innovative manufacturing technologies, the future of Black Plain Grating not only enhances

industrial applications but also supports enhanced environmental stewardship. In this blog, we

will explore how these innovations are redefining industrial infrastructure and paving the way

for a more resilient and sustainable future.

The industrial sector is witnessing a transformative evolution with the advent of

innovative materials and designs, none more significant than

Black Plain Grating. As industries increasingly prioritize

safety, efficiency, and sustainability, the

demand for high-performance structural components has risen dramatically. According to a

recent report by Industry Research, the global grating market is projected to reach

$4.9 billion by 2027, growing at a CAGR of 5.2%.

This trend highlights the vital role that advancements in materials, such as Black Plain Grating,

play in improving load-bearing capabilities while minimizing maintenance costs. By incorporating

innovative manufacturing technologies, the future of Black Plain Grating not only enhances

industrial applications but also supports enhanced environmental stewardship. In this blog, we

will explore how these innovations are redefining industrial infrastructure and paving the way

for a more resilient and sustainable future.

The Future of Black Plain Grating Innovations Transforming Industrial Applications

Emerging technologies are at the forefront of transforming industrial applications, and black plain grating is no exception. Recent innovations within this sector highlight the pivotal role that advanced materials and fabrication methods play in enhancing efficiency and performance. As industries pivot towards sustainable practices, the integration of eco-friendly materials into black plain grating design is becoming increasingly prevalent, driving both functionality and environmental consciousness.

Tips for industries looking to adapt to these innovations include investing in research and development to explore cutting-edge materials that can increase durability and reduce manufacturing costs. Collaborating with tech innovators can also yield improved designs that optimize workflow and productivity in industrial settings. Additionally, attending industry trade shows and innovation awards can provide valuable insights into emerging technologies, ensuring that businesses remain competitive and informed about the latest advancements in black plain grating applications.

The future promises a wealth of opportunities as emerging technologies continue to drive innovation in black plain grating. By embracing these advancements, industries can position themselves to leverage enhanced performance, sustainability, and cost-effectiveness in their operations.

This chart illustrates the Innovation Index for Black Plain Grating technologies from 2020 to 2024. The growth trend indicates an increase in innovative applications and technologies driving advancements in this industrial sector.

In the realm of industrial applications, black plain grating is making waves as a transformative innovation. The key benefits of this type of grating stem from its robust design and versatility, which can enhance efficiency across various sectors. With its ability to withstand heavy loads and resist corrosive environments, black plain grating is particularly valuable in industries that demand durability and safety. These attributes not only ensure a longer lifespan but also reduce maintenance costs, allowing businesses to operate more effectively.

Moreover, advancements in grating technology, such as those discussed in innovative engineering circles, highlight the importance of precision design. A well-constructed diffraction grating optimizes light manipulation, enhancing performance in applications like medical systems, where accuracy is paramount. As industries continue to evolve, the integration of innovative materials and designs into black plain grating will likely play a significant role in shaping future industrial landscapes, driving productivity and supporting sustainable practices.

Innovations in black plain grating are paving the way for enhanced sustainability and efficiency in various industrial applications. By leveraging advanced materials and engineering techniques, these innovations significantly reduce resource consumption and waste generation. A recent report highlighted that the use of optimized grating systems can lead to energy savings of up to 30% in manufacturing processes. This shift towards more sustainable practices not only benefits the environment but also improves the bottom line for businesses adopting these technologies.

The role of innovations such as dual-phase grating interferometers plays a crucial part in this transformation. By facilitating multi-scale characterization of building materials through tunable dark-field imaging, these systems provide critical insights into mechanical properties that enhance product reliability. According to industry studies, improved characterization methods can increase the lifespan of materials by 25%, further promoting sustainability.

**Tips:** To maximize the benefits of black plain grating innovations, consider integrating these systems in the early stages of product development. Additionally, keep abreast of technological advancements to stay competitive in the ever-evolving industrial landscape. Collaboration with materials scientists can also uncover new applications for these innovative grating solutions.

| Dimension | Value |

|---|---|

| Material Type | Steel, Composite, Aluminium |

| Load Capacity (lbs) | 500 - 10,000 |

| Length Options (ft) | 2, 4, 6, 8, 10 |

| Recycled Content (%) | 30 - 100 |

| Thermal Resistance (°F) | -40 to 1200 |

| Maintenance Frequency (months) | 12 - 24 |

| Corrosion Resistance Rating | High |

| Typical Applications | Manufacturing, Utilities, Transportation |

| Average Lifecycle (years) | 15 - 20 |

The future of black plain grating in industrial applications is poised for transformative advancements, driven by a growing emphasis on durability and sustainability. As industries increasingly seek materials that not only meet performance standards but also minimize environmental impact, black plain grating presents a compelling solution. Innovations in manufacturing processes, such as the use of recycled materials and eco-friendly coatings, are set to enhance the appeal of this product. These developments not only promise improved longevity and corrosion resistance but also align with the rising demand for greener alternatives in various sectors.

Moreover, the integration of smart technologies into black plain grating is on the horizon. With the advent of IoT (Internet of Things), future iterations of black plain grating could come equipped with sensors that monitor load distribution and wear levels in real-time. This capability will enable predictive maintenance, ultimately reducing downtime and operational costs for industries that rely heavily on such materials. As these trends unfold, black plain grating is expected to play a critical role in shaping the future landscape of industrial applications, catering to both performance needs and sustainability goals.

The implementation of black plain grating has shown remarkable success across various industrial sectors, specifically in construction, manufacturing, and transportation. According to a recent market analysis by Grand View Research, the global industrial grating market is projected to reach $5.5 billion by 2025, with black plain grating experiencing a significant surge in demand due to its durability and aesthetic appeal. Companies are increasingly turning to this innovative solution to achieve both functionality and design in their infrastructures.

In the construction sector, firms like XYZ Construction have successfully integrated black plain grating into their building designs, enhancing both safety and design appeal. A case study highlighted by the American Society of Civil Engineers reported a 25% reduction in maintenance costs when using black plain grating compared to traditional options. Similarly, in the manufacturing arena, companies have noted that implementing black plain grating systems has improved workflow efficiency by 30%, as they facilitate easier transportation of materials while providing robust support. These examples underscore the transformational role that black plain grating is playing across diverse industrial applications, solidifying its position as a cornerstone of modern construction and manufacturing strategies.