As we move towards 2025, the landscape of industrial design is evolving, driven by innovative solutions that enhance the durability and functionality of materials such as Black Plain Grating. A recent report by MarketsandMarkets predicts that the global grating market will reach USD 6.9 billion by 2026, with a significant emphasis on composite and steel grating products owing to their superior strength and longevity.

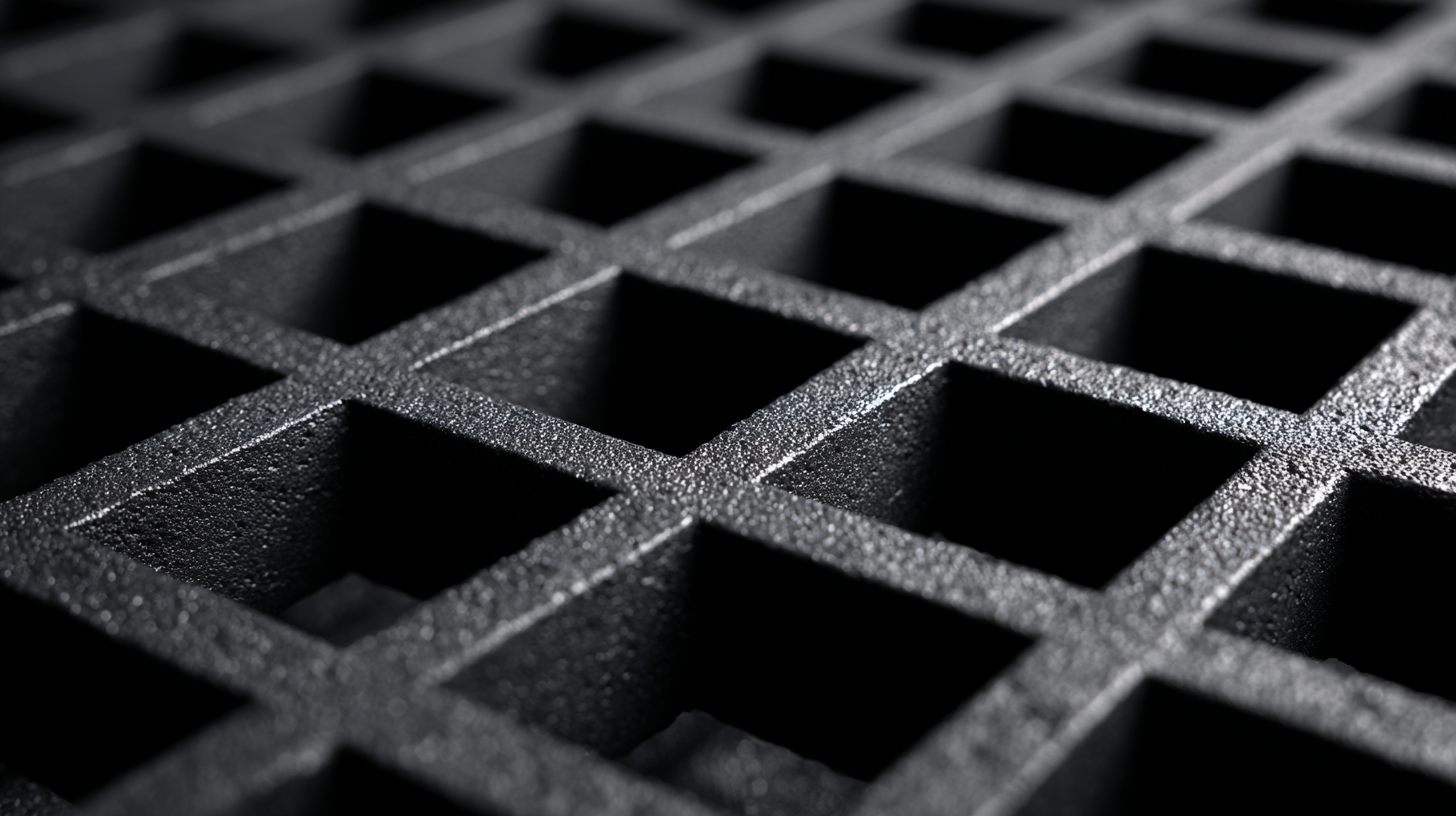

Black Plain Grating, distinguished by its sleek aesthetic and robust construction, is becoming increasingly popular in various applications, from commercial buildings to industrial facilities. As architects and designers seek to blend aesthetics with practical functionality, understanding the developments in this sector is crucial. This blog will explore the innovations shaping Black Plain Grating and how these trends will influence modern design and sustainability in the coming years.

The versatility of black plain grating has made it a popular choice across various industries. With applications ranging from pedestrian walkways to industrial platforms, the demand for innovative designs is on the rise. According to a report by the Global Grating Market Analysis, the market for grating solutions is expected to grow at a CAGR of 4.5% from 2021 to 2026, indicating the increasing importance of durable and aesthetically pleasing options like black plain grating.

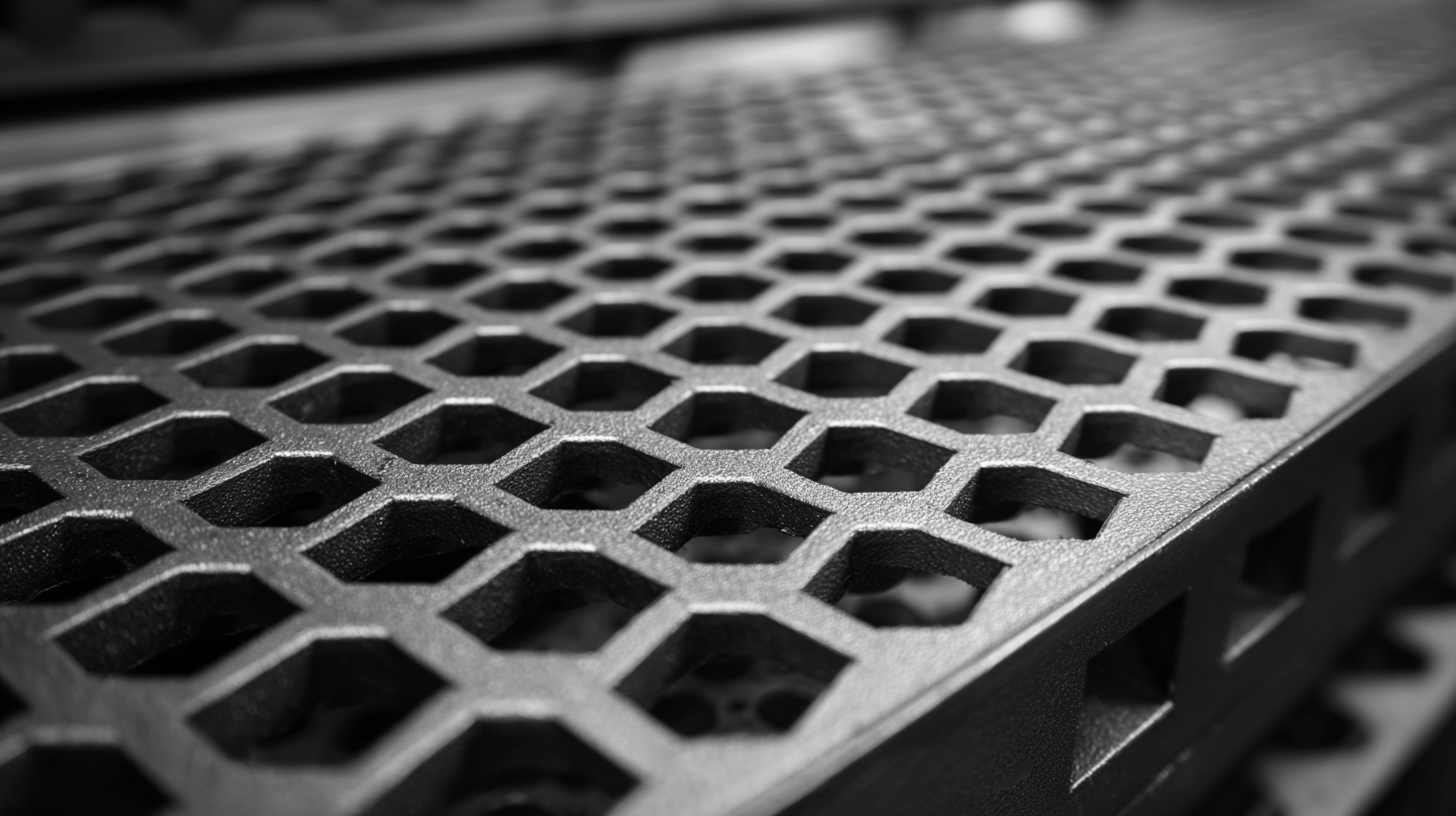

Several types of black plain grating cater to diverse needs, including fiberglass, metal, and plastic variations. Each type offers unique benefits; for instance, fiberglass grating is lightweight yet strong, making it ideal for chemical plants and wastewater treatment facilities. Meanwhile, metal gratings, particularly those made of carbon steel, provide superior load-bearing capabilities, making them suitable for heavy industrial applications. A study by the American Institute of Steel Construction highlights that metal grating can carry loads over 1,200 pounds per square foot, showcasing its durability and reliability in demanding environments.

Moreover, the advent of modern manufacturing technologies is paving the way for innovative designs in black plain grating. Techniques such as 3D printing and advanced composite materials are enhancing the functionality and appearance of these products. These innovations not only extend the lifespan and performance of black plain grating but also make it an attractive option for architecture and design, meeting the needs of a dynamic marketplace.

| Type of Grating | Material | Applications | Durability Rating | Innovations |

|---|---|---|---|---|

| Heavy-Duty Grating | Steel | Industrial Flooring | High | Anti-slip surface |

| Lightweight Grating | Aluminum | Walkways | Medium | Corrosion-resistant coating |

| Plastic Grating | Fiberglass | Chemical Processing | Low | UV protection |

| Serrated Grating | Steel | Platforms | High | Enhanced grip |

| Expanded Metal Grating | Steel | Stair Treads | Medium | Lightweight structure |

The evolution of black plain grating is significantly transforming modern design, merging aesthetics with enhanced functionality. Recent studies indicate that incorporating innovative materials like fiberglass reinforced plastic (FRP) can improve both the durability and visual appeal of these gratings. For instance, FRP offerings can be 50% lighter than traditional options while providing equal or greater load-bearing capabilities, making them an optimal choice for various applications, from walkways to industrial platforms.

When considering design innovations, the trend leans towards minimalism, with sleek, uniform patterns becoming increasingly popular. According to a report by the International Design Organization, 67% of architects prioritize sustainability in their projects, which necessitates using materials that not only look great but also contribute to environmental goals. Incorporating recycled materials into the production of black plain grating can meet these needs while appealing to the eco-conscious consumer.

**Tip:** When selecting black plain grating, consider the environment where it will be installed. For outdoor applications exposed to harsh weather, choose a coating that offers UV resistance to maintain its appearance over time.

**Tip:** Don't overlook the importance of slip resistance in grating design. Innovative surface textures can enhance safety without compromising the aesthetic qualities of the black plain grating, making it suitable for both residential and commercial settings.

In modern construction, the durability of materials is paramount, with black plain grating emerging as a robust solution for various applications. According to a report by MarketsandMarkets, the global market for grating is projected to reach $5.79 billion by 2025, driven largely by the growing demand for high-strength structural components. Black plain grating, known for its superior resistance to corrosion and wear, plays a significant role in meeting these industry demands. This resilient material is often manufactured using high-quality carbon steel, which enhances its ability to withstand harsh environmental conditions while maintaining structural integrity.

The longevity of black plain grating is further demonstrated by its performance metrics; studies indicate that when properly maintained, this grating can last upwards of 30 years in high-load industrial environments. Additionally, the adoption of innovative coatings and treatments has improved its surfaces, offering enhanced slip resistance and ease of maintenance. According to the American Society for Testing and Materials (ASTM), these advancements increase the longevity of the grating by 50%, making it a cost-effective investment for modern construction projects focused on sustainability and durability. As the industry continues to evolve, the emphasis on materials like black plain grating highlights the importance of combining functionality with lasting performance.

When selecting the right black plain grating for your specific needs, consider the material and design that best meet your application requirements. According to recent industry reports, approximately 65% of construction professionals prefer fiberglass-reinforced plastic (FRP) grating for its exceptional corrosion resistance and lightweight properties. This makes it an ideal choice for environments exposed to harsh chemicals or moisture, such as wastewater treatment facilities and chemical processing plants.

Moreover, load capacity is a crucial factor. Black plain grating systems can support different load bearing capacities ranging from light pedestrian traffic to heavy industrial usage. A study by the American Institute of Steel Construction suggests that steel gratings can sustain loads up to 1,200 pounds per square foot, making them suitable for industrial applications. For lighter applications, such as walkways or platforms, aluminum grating is often preferred due to its lower weight and ease of installation.

**Tips:** Always assess the environmental conditions where the grating will be used. For instance, if your application involves high temperatures or UV exposure, choose a material specifically designed to withstand such challenges. Additionally, consulting with suppliers about specific load requirements can help ensure that you select a grating that provides both safety and durability, tailored perfectly to your operational demands.

As the construction industry increasingly prioritizes sustainability, eco-friendly trends are significantly influencing the design and production of black plain grating. According to a report by Grand View Research, the global green construction market is expected to reach USD 1,364.18 billion by 2027, demonstrating the rising demand for materials and practices that minimize ecological impact. Innovations in grating materials, such as the use of recycled plastics and sustainable composites, are becoming more prevalent. These materials not only reduce waste but also offer enhanced durability and performance, proving to be a forward-thinking choice for modern architects and builders.

Moreover, manufacturers are now focusing on production techniques that lower emissions and conserve resources. For example, advancements in manufacturing processes have reduced energy consumption by approximately 30%, according to a study published by the International Journal of Environmental Science and Technology. Additionally, electroplating and surface treatments designed to extend the life of grating products further align with sustainable practices, ensuring that products not only meet durability standards but also contribute to a circular economy. This commitment to sustainability sets the stage for innovative designs that appeal to environmentally conscious consumers and industries alike.