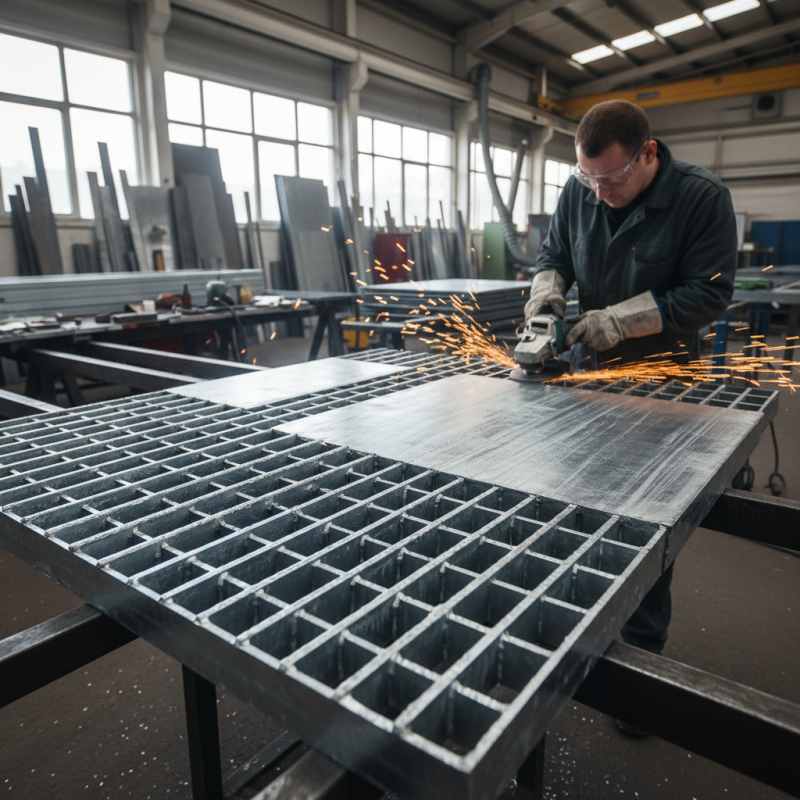

Grating galvanized materials is an essential practice in various industries, ensuring durability and resistance to corrosion. According to industry expert Dr. Emily Thornton, a leading authority in metal fabrication, "The right techniques for grating galvanized materials can greatly enhance both the performance and lifespan of the final product." As industries continue to prioritize efficiency and sustainability, understanding the nuances of grating galvanized materials becomes increasingly critical.

In this guide, we will explore five essential tips for successfully grating galvanized materials, emphasizing methods that yield superior results. Proper techniques not only improve the quality of work but also help in mitigating common challenges faced during the grating process, such as haphazard surfaces and diminished protective coatings. By following these expert recommendations, professionals can achieve a finer finish and maximize the benefits offered by galvanized components. Whether you're an experienced technician or a newcomer to the field, mastering these strategies is vital for advancing your skills in grating galvanized materials.

Galvanized materials, primarily steel coated with a thick layer of zinc, are designed to resist corrosion and offer durability in various applications, from construction to automotive industries. Understanding the properties of galvanized materials is crucial for achieving optimal results when it comes to grating. The process of galvanization not only enhances the surface hardness but also increases the life span of metal components. A report by the American Galvanizers Association indicates that hot-dip galvanized coatings can typically last 50 years or more under mild atmospheres, showcasing the importance of proper handling and processing.

When grating galvanized materials, it is essential to take precautions to maintain their integrity. One tip is to use the right tools; select tools designed for metalworking with carbide tips to minimize wear. Additionally, consider the surface temperature and ambient conditions, as excessive heat generated during grating can damage the zinc coating and reduce corrosion resistance. Regular maintenance of grating tools can also help in obtaining finer results, ensuring consistent texture and finish.

Moreover, proper techniques can lead to better outcomes. Employing a steady, controlled pressure during the grating process is key; applying too much force can lead to uneven surfaces or deformation of the material. In a study conducted by the Fabricators and Manufacturers Association, proper technique contributed to a 25% increase in the quality of the final product. By integrating these tips into your grating process, you can enhance the longevity and performance of galvanized materials effectively.

When it comes to grating galvanized materials, choosing the right grater is crucial for achieving the best results. Galvanized surfaces, often coated with zinc, require tools that can efficiently handle this durable material without causing damage. A good grater should be robust enough to withstand the rough texture of galvanized steel yet fine enough to create a smooth finish. Look for graters with stainless steel blades, as they resist rust and corrosion, ensuring longevity while maintaining performance.

Additionally, consider the size and design of the grater. A larger grater might be more efficient for bigger projects, while a hand-held option can provide better maneuverability for detailed work in tight spaces. Ergonomic handle designs can also enhance comfort during extended use, reducing the risk of hand fatigue. Ultimately, by selecting a grater specifically designed for galvanized materials, you can ensure a cleaner and more efficient preparation process, leading to superior outcomes in your projects.

When grating galvanized materials, achieving the best results requires careful preparation of the surface to ensure optimal adhesion and finish. Start by thoroughly cleaning the galvanized surface with a degreaser or detergent to remove any dirt, oil, or contaminants. This step not only helps in achieving a smoother surface but also prevents any residues from compromising the grating process.

Next, consider lightly sanding the galvanized surface, which can enhance the bond between the galvanized metal and any coating used during the grating process. Using fine-grit sandpaper, gently scuff the surface to create small grooves that will aid in better adhesion. This simple tip can significantly impact the final outcome of your project, providing a more durable and long-lasting finish.

Additionally, applying an appropriate primer designed for galvanized materials can further improve results. Look for a primer that offers excellent adhesion properties and is specifically formulated for use on galvanized surfaces. This preparatory step is often overlooked but is crucial for achieving the best results when grating galvanized materials, ensuring that your final product looks professional and holds up over time.

When it comes to grating galvanized materials, using the right techniques can greatly enhance the quality of your work. One effective method is to ensure that the surface of the material is clean and free from rust or contaminants before starting the grating process. This preparation not only helps in achieving a smoother finish but also prevents clogging of the grater, allowing for better performance.

Another important technique involves selecting the appropriate type of grater for the specific project at hand. Different grating surfaces can yield various results, so it is crucial to choose one that matches the thickness and texture of the galvanized material being worked on. Additionally, applying consistent pressure and using a steady motion while grating can significantly improve efficiency and finish quality. Keeping the grater at an optimal angle will further aid in maintaining control and reducing wear on the grating surface, ultimately contributing to more precise and effective results.

When working with galvanized materials, maintaining your graters is crucial to prolong their life and ensure optimal performance. Galvanized surfaces can be abrasive, causing wear and tear on grater blades. Industry reports indicate that improperly maintained tools can lead to a decrease in efficiency by up to 30%, which can significantly affect project timelines and overall productivity. Therefore, after grating galvanized materials, it is essential to remove any residue and prevent the build-up of zinc particles that could corrode the grater over time.

To ensure longevity, first, thoroughly clean the grater with warm soapy water. Reports suggest that using a non-abrasive sponge effectively removes debris without damaging the surface. After washing, rinse the grater with clean water and dry it immediately to avoid moisture accumulation, which can lead to rust. Regular inspection and maintenance, including oiling the blades with light machine oil, can further protect against corrosion. According to the National Institute of Repair and Maintenance, tool maintenance can increase the lifespan of graters by an average of 50%, making these post-use practices essential for efficiency and cost-effectiveness in any workshop or manufacturing setting.

| Tip | Description | Maintenance Advice |

|---|---|---|

| Choose the Right Grater | Select a grater specifically designed for galvanized materials to enhance efficiency. | Clean the grater thoroughly after use to prevent corrosion. |

| Wear Protective Gear | Using gloves and goggles can help prevent injury from sharp edges and metal shavings. | Inspect your gear for damage after use and replace if necessary. |

| Maintain a Steady Hand | Grate with consistent pressure to ensure an even finish without risking slips. | Store graters in a designated spot to avoid accidental damage. |

| Use Lubrication | Applying a light coat of lubricant can reduce friction and improve performance. | Wipe down grubby surfaces after lubrication to avoid rust buildup. |

| Regularly Inspect Graters | Check for damage or wear and replace as needed to maintain performance. | Store graters in a dry place to prolong their lifespan. |