When it comes to selecting materials for industrial applications, the choices can be overwhelming. However, one option stands out due to its numerous advantages: Grating Galvanized. This durable and versatile material has become increasingly popular in various sectors, from manufacturing to construction, thanks to its ability to withstand harsh environments and heavy loads. Grating Galvanized not only provides exceptional strength and stability but also offers long-lasting protection against corrosion, making it ideal for outdoor and indoor use alike. In this blog, we will explore the five essential benefits of choosing Grating Galvanized for your industrial needs, highlighting why it is a superior choice in today's market. Whether you are refurbishing an existing facility or planning a new project, understanding these key advantages will help you make an informed decision that meets your operational requirements and enhances overall safety.

Galvanized grating is becoming an increasingly popular choice in industrial applications due to its numerous advantages. One key benefit is its superior corrosion resistance. Traditional materials can deteriorate quickly when exposed to harsh environments, but galvanized steel is coated with a protective layer of zinc, ensuring longevity even in extreme conditions. This d durability not only extends the lifespan of the grating but also reduces maintenance costs significantly, allowing businesses to allocate resources more efficiently.

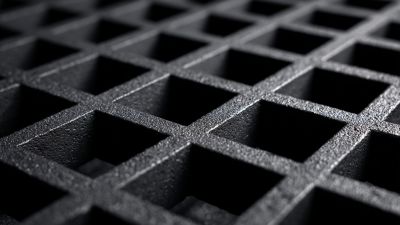

Another notable advantage is the enhanced safety that galvanized grating provides. Its slip-resistant surface ensures that workers can navigate facilities without fear of accidents, which is crucial in industrial settings where heavy machinery and equipment are present. In addition, the open design of grating allows for effective drainage, minimizing the risk of standing water and further enhancing workplace safety. By opting for galvanized grating, industries can create a safer environment while also benefiting from a financially prudent choice that meets their operational needs.

When it comes to selecting materials for industrial applications, enhanced corrosion resistance stands out as a critical factor. Grating galvanized steel, known for its superior protective coating, offers an effective solution to combat corrosion in harsh environments. Recent studies highlight the importance of advanced coatings—such as CeO2 hybrid SiO2 microcapsules and graphene-reinforced epoxy coatings—which significantly improve the corrosion resistance of metals used in industrial settings. For instance, the incorporation of dopamine into polyethylene glycol can achieve a 30% increase in corrosion resistance compared to non-treated surfaces.

Furthermore, innovative methodologies like electrochemical migration of coatings show promise for increasing the durability of galvanized surfaces. A recent comparative study indicated that epoxy coatings functionalized with inhibitor-loaded graphene oxide nanoribbons improve corrosion inhibition by 40% over traditional coatings. Such advancements affirm the necessity of choosing grating galvanized materials as they not only prolong the lifespan of structural components but also reduce maintenance costs associated with corrosion damage. By investing in these cutting-edge solutions, industries can enhance operational efficiency while ensuring longevity and reliability in their infrastructure.

Grating galvanized surfaces play a crucial role in enhancing safety features within work environments, particularly in industries like construction and mining. One of the essential benefits of grating galvanized is its slip-resistant properties, which significantly reduce the risk of accidents related to slips and falls. These surfaces enable workers to maintain better footing under challenging conditions, ensuring a safer work experience overall.

Moreover, the durability of galvanized grating contributes to long-term safety. Its resistance to rust and corrosion extends the lifespan of the flooring, reducing the chances of wear and tear that could compromise structural integrity. This is especially important in environments exposed to harsh weather, where the consequences of accidents can be dire.

Tips: When selecting grating galvanized for your facility, consider options that feature a textured surface for enhanced grip. Additionally, ensure regular inspections and maintenance to keep the safety features functioning optimally. Lastly, training employees on the importance of using designated walkways and areas equipped with grating galvanized will further reinforce a culture of safety on-site.

When considering grating options for industrial needs, galvanized grating stands out not only for its durability but also for its cost-effectiveness over time. The initial investment in grating galvanized may be slightly higher than that of other materials, but its robust design and resistance to corrosion significantly reduce maintenance and replacement costs. Over the years, companies that opt for galvanized grating often find that savings on repairs and longer lifespans translate to lower overall expenses, making it a smart financial choice.

**Tips for Cost-Effectiveness:**

1. Assess your long-term needs before purchasing. Although cheaper options might be tempting, consider the potential costs associated with repairs and replacements in the future.

2. Look for suppliers that offer warranties or guarantees on their galvanization process. This ensures that you are getting a quality product, which will save you money in the long run.

3. Regular maintenance checks can prevent small issues from escalating. Keeping an eye on your galvanized grating can help extend its lifespan and efficacy.

By focusing on cost-effectiveness and longevity, investing in grating galvanized aligns well with sustainable industrial practices, ultimately enhancing both performance and profitability.

Grating galvanized steel is increasingly becoming the material of choice across various industries due to its remarkable versatility and durability. From construction sites to manufacturing facilities, the unique properties of galvanized grating make it an ideal solution for heavy-duty applications. A recent industry report noted that the demand for galvanized grating in the industrial sector is projected to grow by 10% annually, fueled by its ability to withstand corrosive environments while maintaining structural integrity.

In construction and architecture, galvanized grating is utilized for walkways, platforms, and staircases, offering both safety and functionality. Its open design allows for excellent drainage, reducing the risk of slip hazards. Moreover, in the chemical processing industry, where exposure to aggressive substances is common, the protective coating of galvanized steel ensures long-lasting performance, with a lifespan extending up to 30 years compared to uncoated alternatives.

**Tip**: When selecting grating galvanized for your project, consider factors such as load capacity and spacing requirements to optimize performance. Additionally, ensure that the material complies with relevant industry standards for safety and quality assurance. Investing in the right specifications can significantly enhance the longevity and safety of your installations across various industrial applications.