In industrial settings, Galvanized Steel Bar Grating is essential. Its durability and strength make it a popular choice for flooring. This material stands up well to harsh conditions, extending its lifespan.

Installing Galvanized Steel Bar Grating can be tricky. Proper measurements and tools are crucial. Without attention to detail, mistakes can happen. Poor installation might lead to safety hazards or damage. Regular maintenance checks are necessary to ensure safety.

Understanding the application of Galvanized Steel Bar Grating enhances its efficiency. Different environments demand specific features. Reflect on your needs before choosing materials. It's vital to consider load requirements and environmental factors. Practical knowledge helps in making informed decisions.

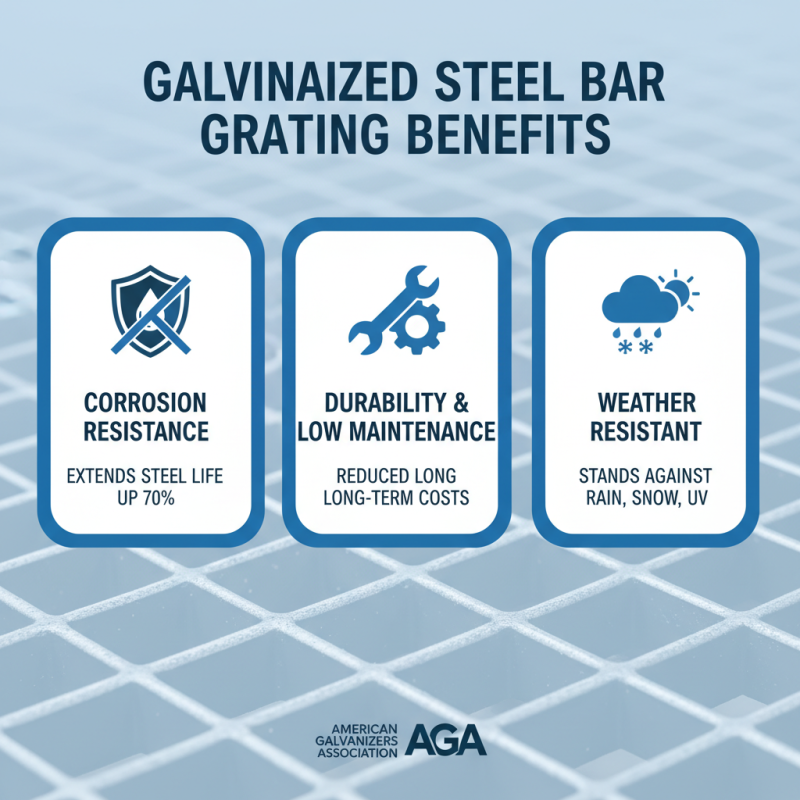

Galvanized steel bar grating offers numerous benefits for construction projects. One major advantage is its corrosion resistance. According to the American Galvanizers Association, galvanized coatings can extend the life of steel by up to 70%. This durability helps reduce long-term maintenance costs. Construction sites often face various weather challenges. Galvanized steel stands strong against rain, snow, and UV exposure.

Moreover, the lightweight nature of galvanized steel makes it ideal for many applications. It allows for easy handling and installation. This can lead to reduced labor costs and time savings during construction. A report from the National Institute of Standards and Technology highlights that lightweight materials can improve project efficiency by up to 30%.

However, some challenges exist. Over time, grating may wear down in high-traffic areas. Regular inspections are essential. Despite its strengths, integrating galvanized steel properly is crucial. The wrong installation can lead to issues down the line. Careful planning and execution are necessary for the best results.

Choosing the right galvanized steel bar grating is crucial for any project. One key factor is load capacity. Different applications require different strength levels. Understanding the expected loads helps in selecting the appropriate grating thickness.

Another important aspect is spacing. Grating bars come in various widths. The spacing between the bars affects drainage and airflow. Narrow spacing may be suitable for smaller debris, while wider spacing allows for better drainage.

You should also think about the installation environment. Environmental factors like humidity and exposure to chemicals can impact the longevity of the grating. Galvanized steel is typically rust-resistant, yet certain conditions can pose risks. Regular maintenance and inspection are essential. Reflecting on these considerations can enhance the effectiveness of your galvanized steel bar grating.

Installation of galvanized steel bar grating requires careful planning. Begin by reviewing the site conditions. Ensure the area is free from debris. Measure the space accurately to determine how much grating is needed. Cutting the grating might be necessary for a correct fit. Use proper tools for this task to avoid injuries.

When installing, secure the grating to the supports properly. This step is often overlooked, leading to potential hazards. Use appropriate fasteners that can withstand the load and environment. Regular inspections during and after installation ensure everything remains stable. Remember, neglecting these checks can lead to significant issues later.

Finally, consider how the grating will be used. High foot traffic areas require more attention. Ensure the grating has sufficient grip to prevent slips. Reflecting on the installation process will help improve future projects. It may be easy to rush through, but patience is key.

Proper maintenance of galvanized steel bar grating is crucial for longevity. Routine inspections are essential. Look for signs of wear, such as rust or deformation. It's easy to overlook these details. A small rust spot can lead to bigger issues. Take time to check regularly.

Cleaning is another key practice. Debris accumulation can cause corrosion. Use a pressure washer to remove dirt and grime. In areas with heavy traffic, more frequent cleaning is advisable. After cleaning, inspect for damages.

Additionally, applying a protective coating can enhance durability. This step can be easily skipped but is really important. Consider the environment where the grating is placed. Harsh conditions may require more frequent maintenance. Ignoring these factors can lead to costly replacements. Putting in the effort will pay off in the long run.

| Maintenance Practice | Frequency | Tools Required | Description |

|---|---|---|---|

| Visual Inspection | Monthly | None | Check for signs of wear, rust, or damage. |

| Cleaning | Quarterly | Pressure Washer | Remove debris, dirt, and grime to prevent corrosion. |

| Rust Treatment | Annually | Wire Brush, Rust Inhibitor | Treat any rust spots with appropriate anti-rust products. |

| Repainting | Every 3-5 years | Paint, Brush or Sprayer | Apply a new coat of paint to protect against corrosion. |

| Load Assessment | Bi-Annually | Load Gauge | Ensure that the grate is not subjected to more weight than it can handle. |

When it comes to using galvanized steel bar grating, safety standards are paramount. These standards ensure that the grating can support expected loads while maintaining structural integrity. It is crucial to understand the load capacity before installation. Different projects have varying requirements, and selecting the right type of grating is essential.

Load capacity is influenced by factors such as bar size, spacing, and overall design. Each application, from walkways to heavy-duty platforms, demands specific engineering considerations. Misjudging the load could result in dangerous situations. It’s wise to consult engineering guidelines to assess the capacity accurately.

In practice, regular inspections are often overlooked. Routine checks can identify wear and tear, ensuring longevity. Ignoring small issues may lead to significant problems over time. Proper maintenance prolongs the grating's life and safety. Each installation must be carefully evaluated, considering unique environmental factors and potential load shifts.