When selecting galvanized steel bar grating, making an informed choice is crucial. James Anderson, a leading expert in industrial materials, emphasizes, “Quality is key in choosing the right grating.” This statement highlights the importance of understanding the nuances of galvanized steel bar grating.

Galvanized steel bar grating offers durability and rust resistance, essential for various industrial applications. However, customers often overlook the significance of load capacity and spacing. These factors can impact the performance of the grating in challenging environments. It’s vital to consider specific project requirements before finalizing a decision.

This industry can feel overwhelming, filled with jargon and varying standards. Striking the right balance between cost and quality is not always easy. Remember, cutting corners can lead to future problems. Reflecting on these elements can lead to a more satisfying purchasing experience in galvanized steel bar grating.

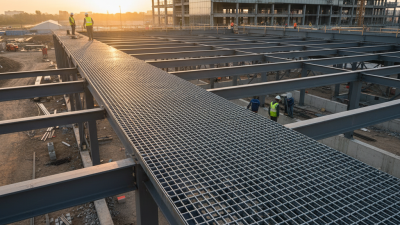

Galvanized steel bar grating is a versatile material used in various applications. It offers strength and durability, making it suitable for industrial settings. The galvanized coating provides excellent corrosion resistance, which is crucial in harsh environments. Many users find it beneficial in walkways and platforms. However, some might overlook the importance of choosing the right gauge. A lightweight option may not support heavy loads.

In addition to structural integrity, consider the spacing of the bars. A tighter spacing can prevent small items from falling through, making it ideal for specific tasks. While some grating may be visually appealing, functionality should remain a priority. Improper choices can lead to safety hazards. Users should think about their actual needs before making a decision.

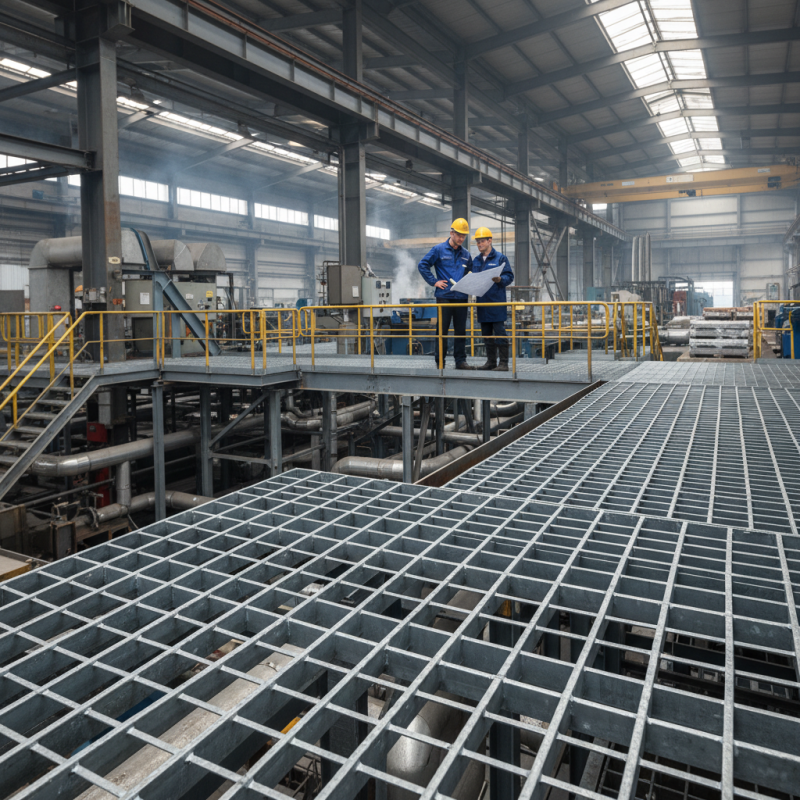

Installation can also present challenges. It’s critical to ensure a secure fit, as gaps can create risks. Be aware that improper installation might lead to maintenance issues later. Regular checks can help identify wear and tear early. Ultimately, being informed and reflective on these aspects can help in selecting the best galvanized steel bar grating for your projects.

When selecting galvanized steel bar grating, several key factors require your attention. Understand the environment where the grating will be installed. Will it face heavy foot traffic or machinery? The load-bearing capacity is crucial. Always check the specifications for weight limits.

Another important tip is the spacing of the bars. Consider how the grating will be used. Wider spacing might allow dirt to fall through but may not be safe for all applications. If children or pets will be around, tighter spacing is better.

Corrosion resistance is vital. Galvanized steel offers good protection, but not all coatings are equal. Examine the finish for potential weaknesses. Consider the overall design too. Some styles complement certain architectural themes better. Reflect on these points carefully. They can impact both safety and aesthetics.

| Factor | Considerations | Benefits |

|---|---|---|

| Load Capacity | Evaluate the weight the grating will support. | Ensures safety and structural integrity. |

| Spacing | Determine the bar spacing based on needs. | Optimizes drainage and traction. |

| Corrosion Resistance | Check the quality of the galvanization process. | Prolongs the lifespan of the grating. |

| Application | Identify the specific use case (e.g., industrial, commercial). | Ensures compatibility and functionality. |

| Compliance | Verify if it meets local and industry standards. | Reduces legal and compliance risks. |

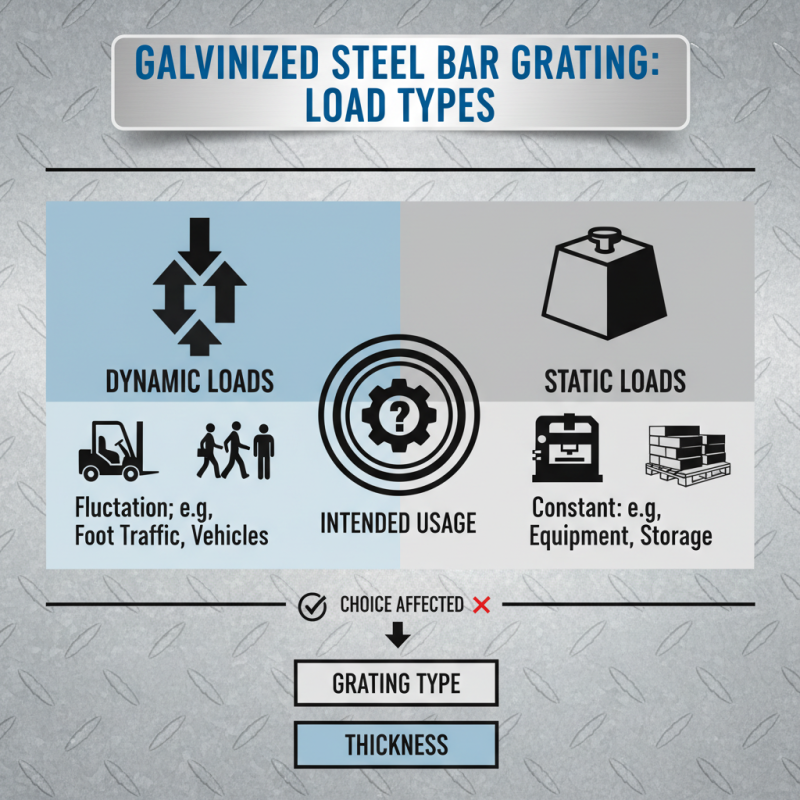

When evaluating the load capacity of galvanized steel bar grating, understanding the types of loads is crucial. Steel grating systems are often subjected to dynamic and static loads. Dynamic loads can fluctuate, while static loads remain constant. It's important to consider the intended usage. This affects the choice of grating type and thickness.

Spacing between the bars is equally significant. Proper spacing not only affects aesthetics but also impacts strength. Standard spacing often varies from 1 to 4 inches. Wider spacing could lead to a decrease in load capacity. It's essential to find the right balance. Too much space may compromise safety.

When designing for specific applications, remember to review industry standards. These guidelines can provide insight into load ratings. However, they may not be exhaustive. You might need to conduct your calculations or consult professionals. Always be ready to reevaluate choices based on trial and error. Factors like material fatigue or environmental conditions can change performance. Ensuring safety should always come first.

Corrosion resistance is crucial when selecting galvanized steel bar grating. The zinc coating protects the steel from rust and deterioration. A report by the American Galvanizers Association states that hot-dip galvanizing can extend the life of steel structures by 50 years or more. This speaks volumes about its effectiveness in harsh environments.

Many factors impact the performance of galvanized grating. For instance, galvanized coatings can vary in thickness. Thicker coatings provide better protection, particularly in corrosive settings. It's reported that a standard thickness of 85 microns can resist maintenance for up to 25 years. However, conditions such as humidity and exposure to chemicals can significantly reduce this lifespan.

While galvanized steel is robust, it’s not fail-proof. Some installations may show wear sooner than expected. Regular inspections can help identify issues early on. Understanding the environmental impact is essential. The zinc coating may degrade under specific conditions, necessitating replacement sooner than planned. Proper application of coatings and attention to environmental factors should never be overlooked.

When selecting galvanized steel bar grating, cost and quality often collide. The average price for steel grating can range between $10 to $30 per square foot, depending on various factors. A report from the Steel Grating Manufacturers Association indicates that specifying higher quality materials can lead to a 15-20% increase in initial costs. However, these initial investments may offer significant long-term savings through reduced maintenance and increased durability.

Analyzing budget constraints is essential. Projects can face tight budgets, leading to compromises. Opting for lower-quality steel grating may save money upfront. Yet, it can result in higher maintenance costs later. For instance, safety audits often indicate that inferior materials lead to higher accident rates, ultimately costing more in liability claims. Stronger, more durable grating may prevent accidents and decrease long-term expenses.

It's crucial to weigh the trade-offs. Quality grating supports heavier loads and lasts longer under harsh conditions. Data shows that grating made from treated steel can outperform untreated options by 50% in terms of lifespan. Balancing cost and quality requires careful contemplation. Each project's unique demands must guide the decision-making process. Making a hasty choice may lead to regrets later. Consider not just the price but the broader implications of your selection.