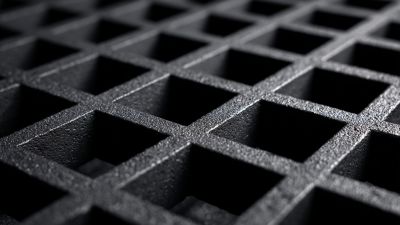

In the evolving landscape of construction and architectural design, Black Plain Grating has emerged as a vital component, revered for its durability and versatility. According to a recent industry report by MarketsandMarkets, the global grating market is projected to reach USD 4.3 billion by 2025, with a significant segment attributed to black plain grating, primarily due to its applications in industrial and commercial settings. This specialized grating type not only enhances structural integrity but also offers aesthetic appeal, making it a preferred choice among architects and engineers alike.

As buyers worldwide navigate through varying options, understanding the distinct types of Black Plain Grating will empower them to make informed decisions that align with their project requirements and budget constraints. This blog aims to provide a comprehensive comparison of these grating types, catering to global buyers looking for clarity in their selection process.

Black plain grating is widely utilized across various industries, from construction to oil and gas, due to its durability and design versatility. When evaluating the key types of black plain grating, it is crucial for buyers to consider materials used, load-bearing capacities, and environmental resistance. According to a 2021 market report by Mordor Intelligence, the global grating market is expected to reach $6.14 billion by 2026, with black plain grating constituting a significant segment due to its aesthetic appeal and functional properties.

Buyers should also assess the attributes that differentiate various grating types. For instance, fiberglass reinforced plastic (FRP) grating is lauded for its resistance to corrosive environments and weighs significantly less than steel options. Meanwhile, steel grating remains preferable for heavy load applications, given its robust load-bearing capabilities. A report by MarketsandMarkets suggests that FRP grating is projected to grow at a compound annual growth rate (CAGR) of 4.8% from 2021 to 2026, emphasizing the increasing preference for lightweight and corrosion-resistant options in the market. Understanding these attributes enables buyers to make informed decisions that align with their specific operational needs.

This chart represents the estimated sales volume of different black plain grating types encountered in the global market. It provides a visual comparison to assist potential buyers in understanding market preferences and making informed purchasing decisions.

The black plain grating market has undergone significant transformations, driven by changes in demand and supply dynamics across various industries. As urbanization and infrastructure development accelerate worldwide, the need for durable and corrosion-resistant materials has surged. Black plain grating, known for its safety and versatility, has become increasingly popular in construction, transportation, and industrial applications. This heightened demand is reflected in market trends, indicating a steady growth trajectory in production and sales.

On the supply side, manufacturers are adapting to meet the evolving needs of global buyers. Innovations in materials technology and advancements in production methods are enabling suppliers to offer a wider range of grating types that cater to specific industry requirements. However, challenges such as fluctuating raw material costs and regulatory changes pose risks to supply stability. As buyers become more discerning, suppliers must focus on quality, customization, and sustainability to maintain a competitive edge in this dynamic landscape. The interplay between demand pressures and supply capabilities will continue to shape the black plain grating market for the foreseeable future.

When selecting black plain grating types for various applications, understanding the performance metrics related to strength and durability is crucial for buyers globally. Different types of grating, such as steel, fiberglass, and aluminum, exhibit varying characteristics that influence their suitability for specific environments. Steel grating, for instance, is renowned for its exceptional load-bearing capability, making it an ideal choice for heavy-duty applications in industrial settings. However, its susceptibility to corrosion necessitates proper protective treatments to enhance longevity.

In contrast, fiberglass grating offers an impressive resistance to environmental degradation and chemical exposure, making it a popular choice in corrosive environments. Although it may not match the load capacity of steel, fiberglass is lightweight and often easier to install. Aluminum grating strikes a balance between strength and weight, providing a durable option for applications where both properties are essential. By thoroughly comparing these metrics, buyers can make informed decisions that align with their project's specific requirements, ensuring enhanced performance and longevity of their grating solutions.

The economic viability of different black plain grating solutions is a critical consideration for global buyers. Various studies indicate that the cost of black plain grating can vary significantly based on material choice, production method, and intended application. For instance, galvanized steel grates typically range from $30 to $50 per square meter, while more specialized options, like stainless steel, can cost up to $100 per square meter due to their durability and resistance to corrosion. This economic assessment is essential for industries that prioritize long-term investment and maintenance costs.

Furthermore, a recent techno-economic analysis highlighted that integrating advanced waste treatment technologies, such as pyrolysis and incineration in a poly-generation system, can significantly improve cost-efficiency. These systems not only generate essential outputs like electricity and steam but also enhance the economic framework by utilizing waste as a resource, converting it into valuable energy forms. Reports suggest that such systems can reduce overall operational costs by up to 30%, making them an attractive option for industries looking to balance environmental sustainability with economic performance. Thus, understanding both the cost implications and technological advancements in the grating sector is crucial for informed purchasing decisions.

| Grating Type | Material | Load Capacity (lbs) | Thickness (inches) | Price per sq. ft. ($) |

|---|---|---|---|---|

| Standard Black Grating | Steel | 1,200 | 0.5 | 12.50 |

| Heavy-Duty Black Grating | Aluminum | 2,500 | 0.75 | 18.00 |

| Lightweight Black Grating | Plastic | 800 | 0.4 | 9.00 |

| Eco-Friendly Black Grating | Composite | 1,400 | 0.6 | 15.00 |

When considering black plain grating products, it’s crucial for global buyers to be aware of the compliance and certification standards that govern these materials. Different regions have specific regulations to ensure safety, durability, and environmental sustainability. In particular, certifications such as ISO 9001 for quality management and ISO 14001 for environmental management play significant roles in validating manufacturers' efforts to provide reliable and safe products. Understanding these global standards can help buyers make informed decisions and mitigate risks associated with subpar materials.

Additionally, compliance with local and international regulations ensures that the products meet not only the expected quality but also legal requirements. For instance, the American National Standards Institute (ANSI) provides guidelines that must be adhered to in the United States, while European buyers might look for compliance with EN standards. Buyers should prioritize suppliers that can provide clear documentation of compliance and certifications, as these factors significantly impact the performance and longevity of black plain grating in various applications. Investing time to verify these standards can save buyers from future liabilities and enhance overall project reliability.