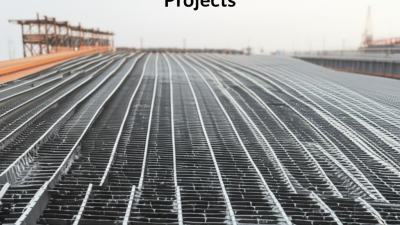

When it comes to industrial applications, selecting the right materials is crucial for ensuring safety, durability, and efficiency. Among these materials, Steel Grating stands out as a versatile and robust option, widely utilized in various sectors, from construction to manufacturing. The different types of steel grating available can cater to specific requirements based on load-bearing capacity, environmental conditions, and aesthetic preferences. This blog aims to guide you through the process of choosing the ideal steel grating for your industrial needs by examining various types, their unique properties, and applications. Understanding these factors will empower you to make informed decisions that will enhance performance and longevity in your industrial operations.

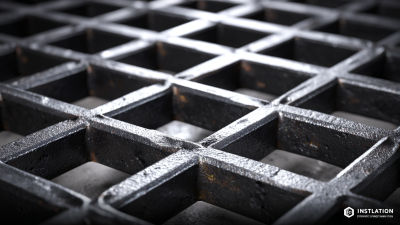

When selecting the right steel grating for industrial applications, it's crucial to understand the various types available on the market. The most common options include welded steel grating, swage-locked grating, and pressure-locked grating. Welded grating is recognized for its robust construction, as the crossbars are welded to the bearing bars, providing excellent strength and stability for heavy loads. This type is ideal for environments requiring high durability, such as manufacturing plants and warehouses.

On the other hand, swage-locked grating features a unique design where crossbars are locked into place by swaging, creating a seamless, flat surface that is suitable for pedestrian traffic. This type is often used in areas where safety and aesthetic appeal are priorities, such as walkways and decorative applications. Pressure-locked grating, known for its high load capacity and lightweight properties, is a versatile choice favored in various industries including oil and gas, where both strength and corrosion resistance are essential. Understanding these differences will guide you in making the best choice to meet your specific industrial needs.

| Type of Steel Grating | Material | Load Capacity (psf) | Applications | Slip Resistance |

|---|---|---|---|---|

| welded steel grating | Carbon Steel | 1000 psf | Walkways, Platforms | High |

| pressure locked grating | Aluminum | 800 psf | Stair Treads, Mezzanines | Medium |

| serrated grating | Stainless Steel | 1200 psf | Food Processing, Chemical Plants | Very High |

| molded grating | Fiberglass | 500 psf | Wet Environments, Pools | High |

When selecting steel grating for your industrial project, several key factors must be considered to ensure optimal performance and safety. First, the load-bearing capacity of the grating is crucial. According to the American National Standards Institute (ANSI), choosing the right load class based on anticipated traffic and weight is vital. For instance, grating used in heavy machinery areas should have a higher class rating capable of supporting loads up to 2,000 pounds per square foot, while pedestrian walkways typically require a lower capacity. Understanding these specifications can prevent premature failure and improve overall infrastructure longevity.

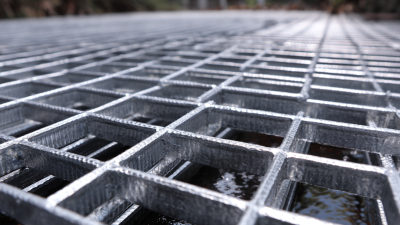

Another significant factor is the material type and coating of the steel grating. A recent market analysis by Grand View Research indicates a growing preference for galvanized steel grating due to its corrosion resistance and durability, especially in harsh environments. The report highlights that galvanized grating can last up to three times longer than untreated options, reducing maintenance costs significantly. Additionally, considering the spacing of the bars is vital for safety; the spacing should align with industry safety standards, typically specified to prevent falls or accidents. These considerations are essential for making an informed decision on the right steel grating that meets both structural and safety requirements.

When selecting steel grating for industrial applications, assessing load capacity and strength requirements is paramount. Steel grating comes in various types and specifications, each engineered to support different loads and resist structural stresses. It’s essential to understand the specific demands of your project, including the maximum load the grating must support and the environment in which it will be used. Consider factors such as exposure to corrosive elements or the potential for dynamic loads, which can significantly influence the performance of the chosen material.

Recent advancements in construction materials, including the study of cold-formed steel structures and hybrid systems, underscore the importance of load-carrying capacity. For instance, research on the performance of cantilever beams with varying perforation patterns reveals how these modifications impact both load capacity and weight efficiency. Such considerations can guide professionals in selecting a steel grating that not only meets the load requirements but also enhances overall structural integrity and sustainability. By thoroughly evaluating these aspects, industries can ensure long-lasting performance and safety in their construction practices.

When selecting steel grating for industrial applications, one of the most critical factors to consider is its resistance to corrosion and environmental influences. Steel grating is often exposed to harsh conditions such as moisture, chemicals, and fluctuating temperatures, which can significantly shorten its lifespan if not properly addressed. To effectively evaluate resistance to corrosion, it's essential to look at the composition of the steel, as well as any protective coatings applied, such as galvanizing or powder coating. These treatments can enhance durability and prolong the performance of the grating in hostile environments.

In addition to corrosion resistance, understanding the specific environmental factors your application will face is crucial. For instance, grating used in coastal areas requires materials that can withstand salt exposure, while those in chemical plants must be compatible with corrosive substances. Comparing different types of steel—such as stainless steel, carbon steel, or fiberglass-reinforced plastic—based on their properties can help you make informed decisions. By taking these considerations into account, you can select the right steel grating that not only meets your industrial needs but also ensures longevity and safety in challenging conditions.

When selecting steel grating for industrial applications,

cost considerations play a crucial role in ensuring

effective budget management. It is essential to assess the total cost of ownership,

which includes not only the initial purchase price but also the long-term maintenance

and replacement costs. Choosing a more durable material may involve higher upfront

investment but can lead to significant savings over time by reducing the frequency

of replacements and repairs.

Tip: Evaluate different types of steel grating materials, such as

carbon steel, stainless steel, or fiberglass, to determine

which aligns with your budget and performance needs. Each material offers varying

levels of corrosion resistance and durability which can

impact overall costs.

In addition to material selection, consider the dimensions and spacing of the grating.

Custom sizing may lead to increased

costs, so it's prudent to assess standard sizes that meet your specifications

without the added expense of customization. By aligning your project requirements

with the available options, you can maximize value while managing budget constraints

effectively.

Tip: Don’t forget to account for delivery fees and any additional costs

associated with installation.

Collaborating with suppliers who offer comprehensive pricing quotes can help eliminate

surprises and facilitate better financial planning for your industrial project.