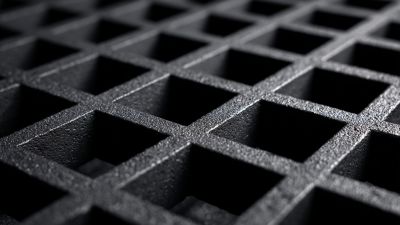

When embarking on a project that requires durable and reliable materials, the choice of grating can significantly impact both functionality and aesthetics. Among the various options available on the market, Black Serrated Grating stands out due to its unique combination of strength, safety, and visual appeal. This type of grating is not only designed to withstand heavy loads but also features a serrated surface that provides excellent slip resistance, making it ideal for environments where safety is a priority.

In recent years, the demand for Black Serrated Grating has grown across various industries, including construction, landscaping, and commercial applications. As it becomes increasingly popular, understanding the factors that influence the selection of the best Black Serrated Grating for your specific needs is essential. This guide will explore the types and characteristics of Black Serrated Grating, as well as key considerations to keep in mind when making your choice. Whether you are looking for grating solutions for a pedestrian walkway, a heavy machinery area, or decorative applications, knowing how to choose the right product can enhance the longevity and effectiveness of your project.

When considering the best black serrated grating for your projects, it is essential to understand the specific features that differentiate various types. The serrated design enhances traction, making it particularly suitable for applications where safety and stability are paramount. Moreover, the color black not only offers aesthetic appeal but also provides benefits such as heat absorption and UV resistance, which can be advantageous in outdoor environments.

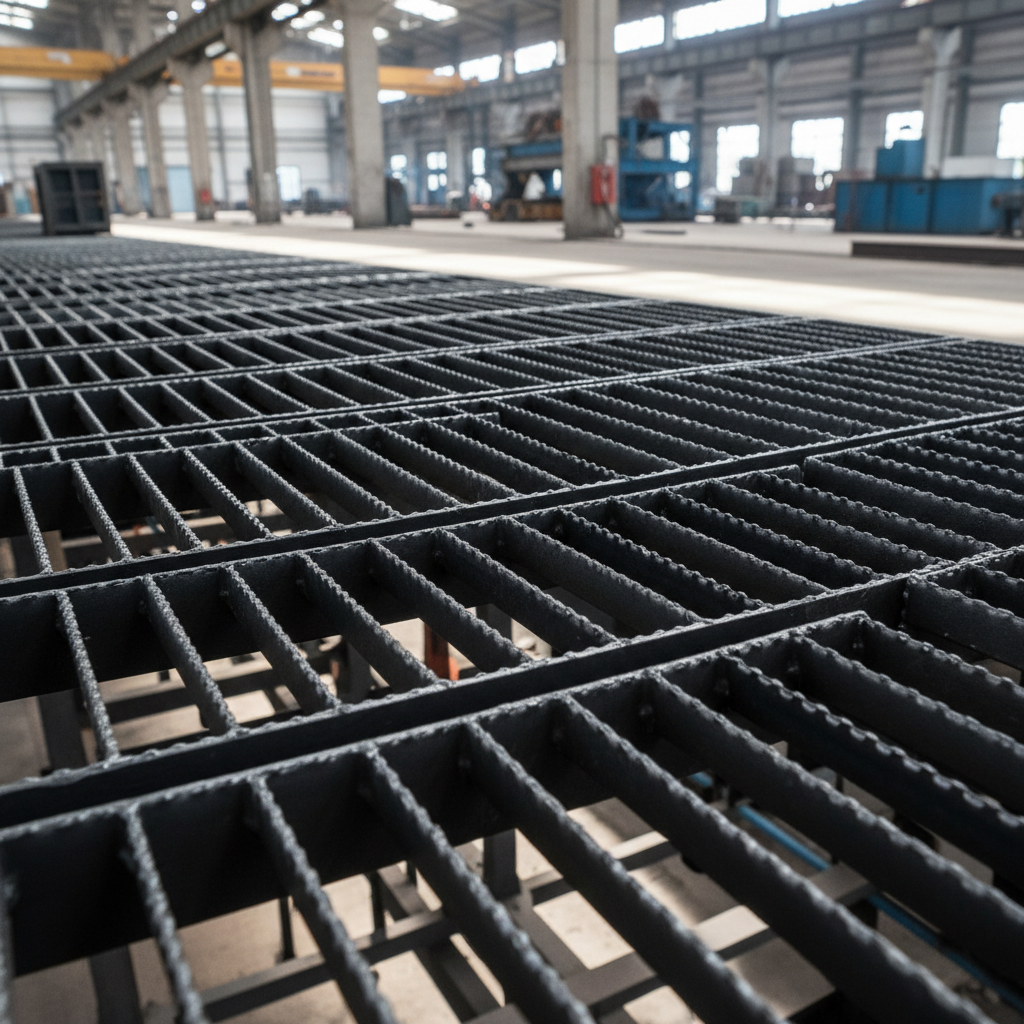

Another critical aspect is the material composition and its impact on durability and maintenance. High-quality black serrated grating is often made from corrosion-resistant materials, ensuring longevity even in harsh conditions. Features like load-bearing capacity and ease of installation should also be evaluated to ensure that the grating meets the demands of your specific project. By thoroughly assessing these features, you can select the most appropriate black serrated grating that aligns with your project requirements and enhances overall performance.

When selecting the best black serrated grating for your projects, evaluating the material durability and performance is essential. According to a report by the American Institute of Steel Construction, serrated grating can enhance slip resistance, making it a preferred choice for industrial environments where safety is paramount. Durability can often be attributed to the material composition, with options like galvanized steel and fiberglass-reinforced plastic (FRP) offering varied resistance to corrosion and impact. For instance, FRP grating typically boasts an impressive resistance to harsh chemicals, making it suitable for chemical processing facilities, as noted in a study by the Composites Industry Association.

Moreover, the performance of grating options is often measured by load-bearing capacity and maintenance requirements. The National Association of Steel Fabricators indicates that heavy-duty steel grating can support substantial loads of up to 5,000 pounds per linear foot, which is critical for high-traffic industrial applications. Conversely, while FRP may have a lower load capacity, it compensates with its lightweight nature and lower maintenance costs. Therefore, the decision should balance immediate material needs against long-term operational efficiency and safety requirements for the specific project at hand.

When selecting the best black serrated grating for your projects, sizing and customization play pivotal roles in ensuring functionality and aesthetic appeal. First, consider the specific application of the grating. Whether it is for flooring, drainage, or seating, different projects will require different dimensions and load capacities. It's essential to assess the intended use environment carefully, as this will dictate the necessary resistance to wear and environmental stress.

**Tips:** Always measure the installation area precisely to avoid misfits. Use templates or mock-ups to visualize the space and ensure the selected grating complements the surrounding structures.

Customization options also matter greatly. Many manufacturers offer choices in thickness, spacing, and surface finish. Determine whether you need a slip-resistant surface or specific hole sizes for drainage purposes. Evaluating these factors early in the design process can prevent costly modifications later.

**Tips:** Reach out to suppliers for samples of different textures and finishes. This hands-on approach will help you make an informed decision about the final look and safety features of your grating.

| Consideration | Description | Recommended Size | Customization Options |

|---|---|---|---|

| Load Capacity | Evaluate the maximum load the grating must withstand. | Class A (Light-duty), Class B (Medium-duty), Class C (Heavy-duty) | Custom thickness options available. |

| Material Type | Choose between steel, fiberglass, or aluminum based on application. | Fiberglass for corrosion resistance, Steel for strength. | Available in various finishes and coatings. |

| Surface Design | Consider anti-slip requirements and texture. | Serrated surface for enhanced grip. | Custom patterns can be designed for specific needs. |

| Size Dimensions | Length, width, and height specifications. | Standard sizes: 24"x48", 36"x72" | Custom lengths up to 96 inches available. |

| Installation Environment | Assess conditions like temperature, moisture, or chemicals. | Use fiberglass in wet or corrosive areas. | Customizable for specific environmental factors. |

When selecting the best black serrated grating for your projects, it’s essential to perform a comparative analysis of cost-effectiveness. Cost-effective grating choices not only cater to your budget but also ensure long-term durability and performance. Consider the initial cost of the grating material, but also factor in the maintenance costs over time. Some materials may be initially cheaper, but they could require more frequent replacements or repairs, thus increasing lifetime expenses.

Tips for choosing the right grating include evaluating the environmental conditions it will face, such as exposure to chemicals, extreme temperatures, or heavy foot traffic. Additionally, look for products that offer warranties or have certifications that affirm their quality and durability. This can significantly impact your overall costs and performance, making your project more efficient and reliable.

Choosing the right manufacturer often plays a critical role in cost-effectiveness. Research various suppliers to find those that not only match your budget but also provide high-quality products. Consider ordering samples to assess the product firsthand, ensuring that you are making a well-informed decision that will serve your project's needs effectively.

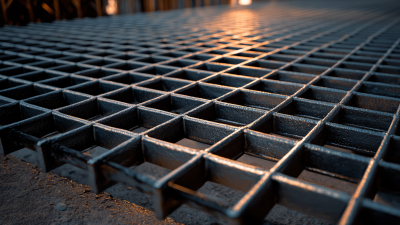

When it comes to selecting black serrated grating for your projects, understanding installation tips and best practices is essential. This type of grating is not only functional but also adds a sleek aesthetic to various applications. The serrated edges provide unparalleled grip, ensuring durability and safety in environments that require a robust flooring solution, like restaurants or commercial kitchens.

Tips: First, ensure the surface where the grating will be installed is properly prepared. It should be clean, dry, and free from any debris that could affect the adhesion. Secondly, always use the appropriate fasteners for your specific grating type; stainless steel fasteners are often recommended for added corrosion resistance. Finally, consider the layout and spacing of your grating. Maintain consistent gaps to allow for drainage and expansion, particularly in areas subjected to moisture.

Choosing the right black serrated grating can enhance both the practicality and visual appeal of your project. By following these installation tips, you'll ensure that your grating not only meets functional requirements but also performs well over time.