Steel grating is an essential component in various industrial applications, providing safety, durability, and efficiency. As industries evolve, the demand for versatile and reliable materials has led to an increasing focus on selecting the appropriate type of steel grating to meet specific needs. This ultimate guide aims to navigate through the various types of steel grating available, understanding their unique features, benefits, and compliance with safety standards. Whether used for flooring, walkways, or drainage systems, the right choice of steel grating can enhance operational safety and performance. In this comprehensive overview, we will explore the key aspects to consider when choosing steel grating, ensuring that you make informed decisions that align with both your operational requirements and safety regulations.

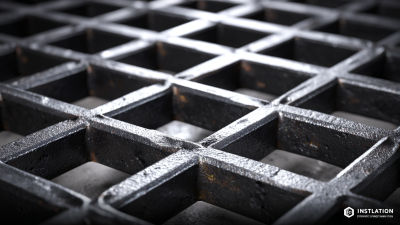

When it comes to industrial applications, selecting the right type of steel grating is crucial for ensuring safety and efficiency. Steel grating is commonly used for flooring, walkways, and drainage covers, and is available in various materials, each with its own set of properties. The most popular types include welded steel grating, press-locked grating, and swage-locked grating. Welded steel grating is renowned for its high load-bearing capacity, making it ideal for heavy-duty applications. Its robust construction ensures longevity, even in challenging environments.

Another important type is press-locked grating, which combines durability with a sleek design. This type is often used in areas where aesthetics matter, such as architectural projects, while still providing a safe walking surface. Finally, swage-locked grating offers a unique balance of strength and weight, suitable for various applications without compromising safety standards. Understanding these different types of steel grating materials allows industries to make informed choices that enhance safety and meet specific application needs.

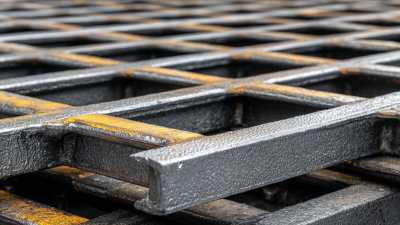

When selecting steel grating for industrial applications, adherence to safety standards is paramount. A key factor to consider is load-bearing capacity. According to the American National Standards Institute (ANSI), steel grating must be able to withstand specific load conditions based on its application. For example, Heavy Duty Steel Grating is often required in environments subject to high foot traffic and heavy machinery, with typical load capacities ranging from 1,500 to 6,000 pounds per square foot.

Another critical aspect is slip resistance. The Occupational Safety and Health Administration (OSHA) mandates that workplaces prioritize worker safety by implementing anti-slip materials. Many industrial steel grating products are designed with serrated surfaces or additional coatings to enhance grip, significantly reducing slip and fall accidents. A recent study highlighted that workplaces equipped with anti-slip grating experienced a 40% decrease in injuries related to falls, underscoring the importance of choosing the right grating. Compliance with these safety regulations not only protects employees but also helps organizations avoid costly litigation and downtime.

When selecting steel grating for industrial applications, evaluating load-bearing capacity and durability is crucial. According to the American National Standards Institute (ANSI), steel gratings must meet specific load criteria to ensure safety and functionality. For instance, a standard steel grating with a load rating of 1,250 lbs can efficiently support foot and vehicular traffic in demanding environments. It is essential to consider the spacing and thickness of the grating bars as these factors significantly influence the overall load-bearing capabilities.

Durability is another key aspect, often determined by the material grade and surface finish. A study by the Steel Grating Manufacturer Association indicates that hot-dip galvanized coatings enhance corrosion resistance, extending the lifespan of steel grating by up to 50% compared to uncoated alternatives. Additionally, the choice between various grating types, such as welded or pressed, can impact durability under different environmental conditions. These insights underscore the importance of thorough evaluation when choosing steel grating to meet safety standards and performance requirements in industrial settings.

| Type of Steel Grating | Load-Bearing Capacity (lbs) | Durability (Years) | Safety Standard Compliance | Common Applications |

|---|---|---|---|---|

| Mild Steel | 500 | 10 | ASTM E-485 | Walkways, Platforms |

| Stainless Steel | 800 | 20 | ASTM A-240 | Food Processing, Chemical |

| Aluminum | 400 | 15 | ANSI/OSHA | Elevated Walkways, Ramps |

| Fiberglass Reinforced Plastic (FRP) | 300 | 25 | ASTM D-638 | Corrosive Environments |

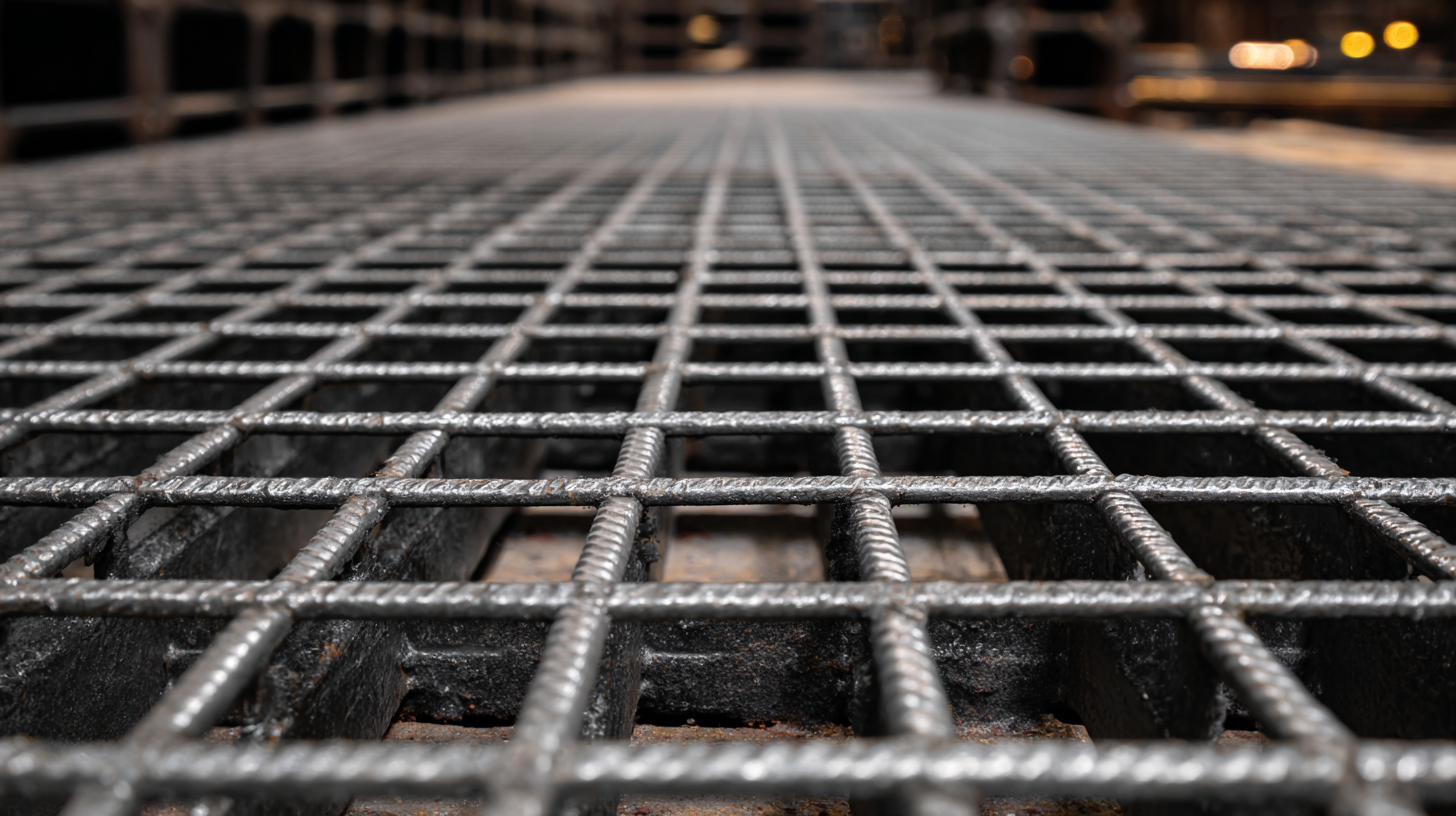

When it comes to ensuring the longevity and safety of steel grating solutions in industrial applications, regular inspection and maintenance practices are crucial. Over time, environmental factors, heavy loads, and chemical exposure can lead to wear and degradation. Therefore, a systematic approach to inspecting the condition of the grating can help identify potential issues before they escalate. Visual inspections should be conducted routinely, focusing on areas prone to corrosion, stress, or impact damage. Any noticeable deformities, rust, or changes in surface texture should be documented for further examination.

In addition to routine inspections, implementing a preventive maintenance schedule can significantly enhance the lifespan of steel grating. This may include minor repairs, cleaning, and protective treatments to mitigate corrosion risks. For instance, applying a protective coating can help safeguard the grating against harsh environmental conditions. Furthermore, the use of non-destructive testing methods allows for more thorough assessments without compromising the integrity of the grating. By adopting these practices, industries can ensure that their steel grating remains safe, functional, and reliable for years to come.

When selecting steel grating for industrial applications, understanding the evolving safety standards and regulations is crucial. As we approach 2025, industries must stay updated on compliance requirements from the Occupational Safety and Health Administration (OSHA). Recent guidelines emphasize the importance of developing comprehensive safety and health programs, focusing on core elements that ensure employee protection and operational efficiency. This aligns with broader trends highlighting the need for innovative safety solutions, including smart technologies that enhance workplace safety and monitor compliance in real-time.

Moreover, the landscape of industrial safety is undergoing significant changes with updates like the ISO 10218 standard for industrial robots. These changes simplify compliance for manufacturers and system integrators, ensuring that they meet modern safety requirements. It is critical for stakeholders in the industrial sector to keep pace with these updates and incorporate them into their safety strategies. By doing so, companies not only protect their workforce but also enhance operational resilience and meet regulatory expectations effectively.