Choosing the right plain steel grating for industrial applications is a critical decision that can significantly impact safety, efficiency, and maintenance costs. According to a report by the Steel Grating Industry Association, the demand for steel grating products has been increasing steadily, with a projected annual growth rate of 4.6% over the next five years.

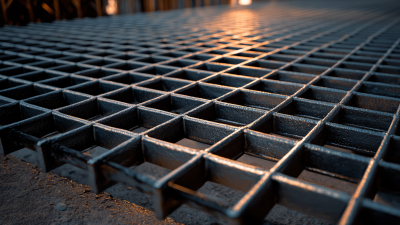

Plain steel grating, known for its durability and versatility, plays a vital role in various sectors such as manufacturing, construction, and energy. With its ability to support heavy loads while providing excellent drainage, selecting the appropriate type of plain steel grating is essential to meet specific industrial requirements.

This guide will explore key factors to consider when choosing the right plain steel grating, helping professionals make informed decisions that align with their operational needs and industry standards.

When selecting plain steel grating for industrial applications, several key factors should be considered to ensure optimal performance and safety. First, the load-bearing capacity is critical. Understanding the specific loads that the grating will need to support, including both static and dynamic loads, helps in choosing the right thickness and material specifications. It's essential to consult load tables or manufacturer recommendations to make informed decisions based on the application.

Furthermore, the environment in which the grating will be installed plays a significant role in material selection. Considerations such as exposure to moisture, chemicals, or extreme temperatures can influence the durability and corrosion resistance of plain steel grating. For areas with high humidity or corrosive agents, opting for galvanized or coated steel grating may enhance longevity. Lastly, safety requirements and local regulations must also be factored in, as they can dictate the design and installation standards needed to comply with industry norms.

By addressing these factors, industries can effectively choose the right plain steel grating tailored to their operational needs.

When selecting plain steel grating for industrial applications, it's crucial to understand the different types available and their specific uses. The most common varieties include welded, swaged, and press-locked grating.

Welded grating is known for its strength and durability, making it ideal for heavy-load areas such as industrial floors and walkways. The joints are welded, providing a robust structure that can withstand substantial weight.

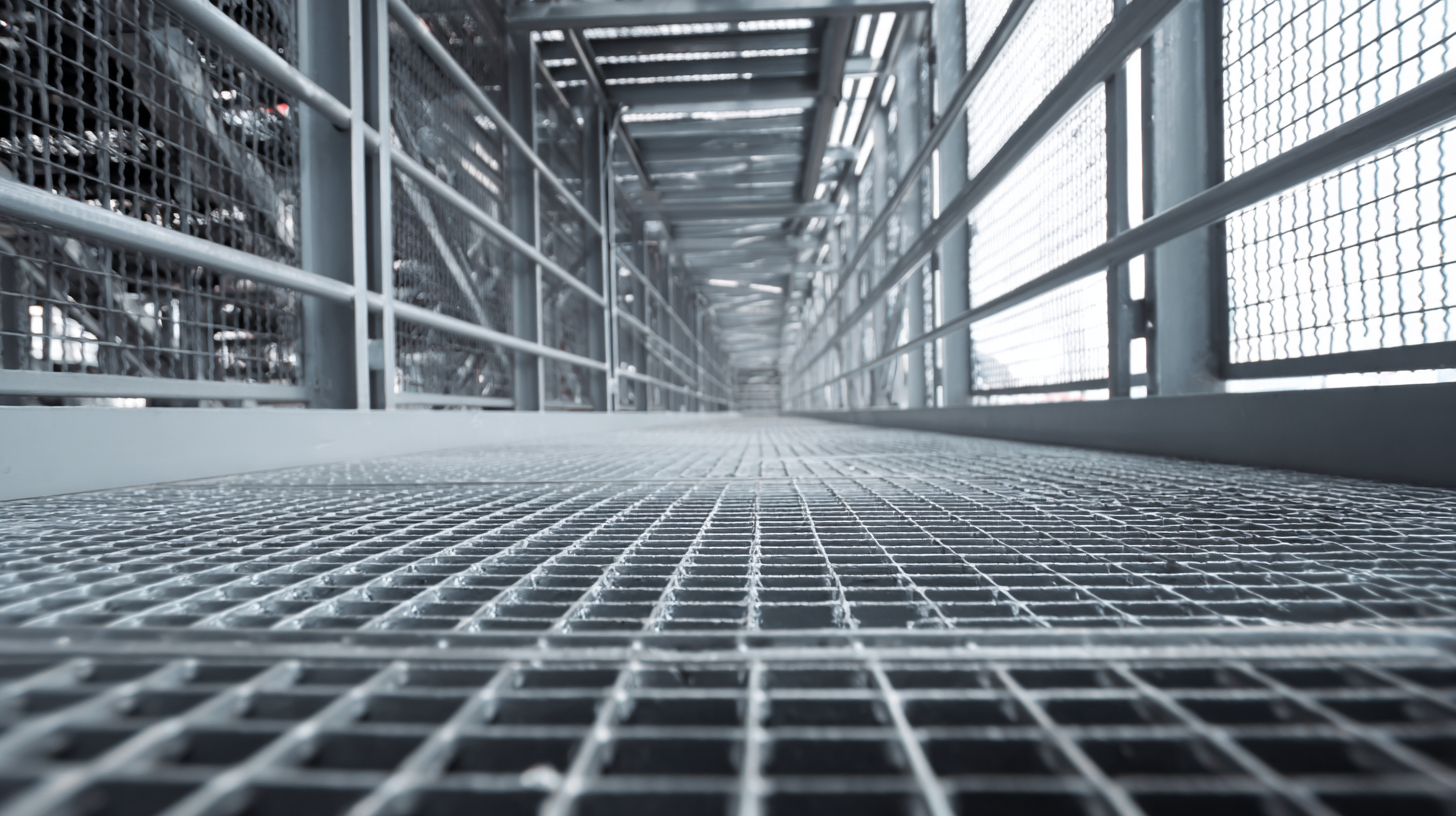

Swaged grating, on the other hand, features a unique design where the cross bars are swaged into the bearing bars, offering a lightweight yet strong option suitable for various applications, including platforms and catwalks. This type allows for better drainage and is often used in environments where water, chemicals, or other fluids are involved.

Lastly, press-locked grating utilizes a locking mechanism for a secure connection, offering a versatile solution for easily removable panels and installations requiring periodic maintenance.

By assessing the specific requirements of your industrial environment—such as load capacity, exposure to chemicals, and maintenance needs—you can choose the right type of plain steel grating to ensure safety and efficiency in your operations.

When selecting the appropriate plain steel grating for your industrial needs, assessing the load-bearing requirements specific to your environment is crucial. Different applications call for varying levels of strength and durability; thus, understanding the maximum load your grating will support is the first step in the selection process. This may involve evaluating factors such as the weight of equipment, foot traffic volume, and any potential impacts from heavy machinery.

Additionally, consider the dimensions and spacing of the grating bars, as they play a significant role in the load capacity. Closer bar spacing can provide added strength and stability for heavier loads, while wider spacing may be suitable for lighter applications. It's essential to consult load tables provided by manufacturers or industry standards to ensure that the chosen grating meets the specific requirements of your facility and adheres to safety protocols. By thoroughly evaluating these factors, you can ensure that your selection of plain steel grating will effectively support your operational needs.

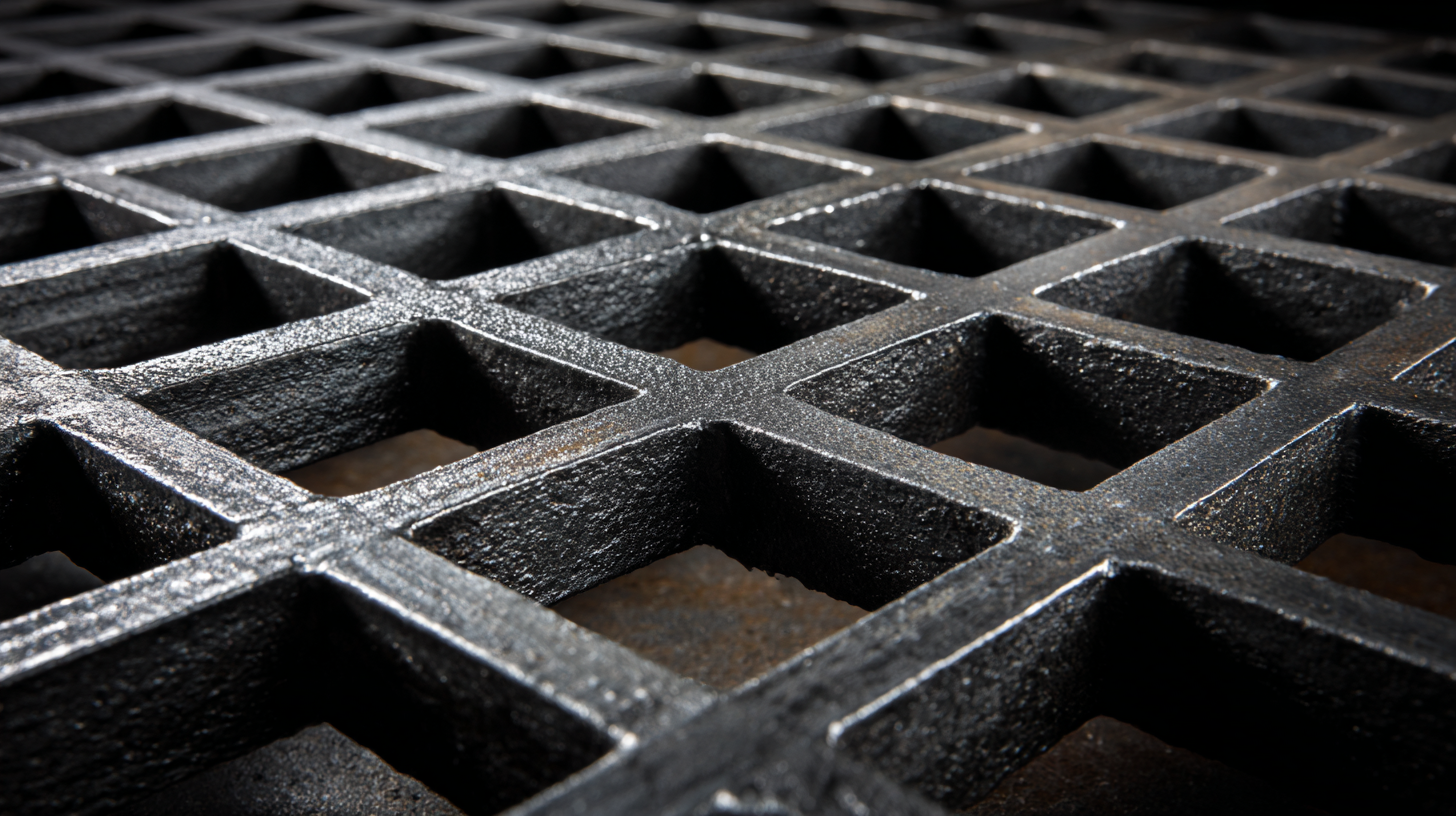

When selecting plain steel grating for industrial applications, evaluating corrosion resistance and maintenance needs is critical to ensuring longevity and functionality. Studies show that steel grating exposed to harsh environments can experience significant degradation over time. According to a report by the American Galvanizers Association, galvanized steel grating exhibits a remarkable lifespan that is nearly 2-3 times longer than unprotected steel in corrosive settings. This makes it a preferred choice for industries operating in coastal or chemical-laden environments.

Maintenance requirements also differ greatly among various types of steel grating. For instance, painted steel grating may require periodic repainting to mitigate corrosion, whereas pre-galvanized options often need minimal upkeep beyond routine cleaning. A study by the National Association of Corrosion Engineers indicates that implementing a proper maintenance schedule for steel grating can reduce overall costs by up to 30% over a 10-year period. Therefore, assessing the specific conditions in which the grating will be used is essential in making an informed choice that balances corrosion resistance with long-term maintenance needs.

When selecting the right plain steel grating for industrial applications, it's essential to balance cost and quality to ensure optimal performance. A recent report from the American Institute of Steel Construction highlights that investing in high-quality grating can significantly reduce maintenance costs over time. While cheaper options may appear attractive initially, they often lead to higher long-term expenses due to frequent replacements and repairs.

When selecting the right plain steel grating for industrial applications, it's essential to balance cost and quality to ensure optimal performance. A recent report from the American Institute of Steel Construction highlights that investing in high-quality grating can significantly reduce maintenance costs over time. While cheaper options may appear attractive initially, they often lead to higher long-term expenses due to frequent replacements and repairs.

Tips: Prioritize grating that meets the necessary load-bearing requirements specific to your application. For instance, a heavy-duty grating made from high-quality steel can withstand substantial weight and resist corrosion, ultimately saving costs in the long run.

Additionally, consider the workplace environment when making your decision. According to the National Institute for Occupational Safety and Health, grating that provides adequate slip resistance is crucial for safety, especially in areas prone to spills or wet conditions. Upfront investments in reliable materials can lead to improved safety conditions and decreased liability risks.

Tips: Look for grating with anti-slip features and a long-life warranty to maximize your investment. Conducting a thorough analysis of your needs versus the offerings of various manufacturers will ensure you make a well-informed decision.