Choosing the right galvanized steel bar grating is essential for any construction project. This material offers strength and durability, making it a popular choice in industrial applications. According to a recent report by the Steel Recycling Institute, about 70% of the steel used in the U.S. is recycled steel. This statistic emphasizes the sustainability of using galvanized steel products.

Galvanized steel bar grating is particularly valued for its corrosion resistance, which extends its lifespan. Various factors come into play when selecting the right type. The choice often depends on load requirements, spacing, and the environment in which the grating will be used. For instance, heavy-duty grating is needed for high-traffic areas, while light-duty options suffice for walkways.

Yet, many overlook the importance of proper installation and maintenance. Incorrect choices can lead to failures, increasing project costs. Understanding load ratings and environmental exposure is crucial. When selecting galvanized steel bar grating, careful consideration is necessary to avoid costly mistakes. A thoughtful approach can result in long-lasting, effective solutions.

When selecting galvanized steel bar grating, it's vital to familiarize yourself with the different types available. There are various options, each designed for specific applications. The most common types include welded and swaged grating. Welded grating features a solid construction, making it ideal for heavy loads. Swaged grating, on the other hand, offers more flexibility and is lighter.

One factor to consider is the load capacity of the grating. Certain projects may require a heavier-duty grating while others don’t. The spacing between the bars is another critical detail. Wider spacing allows for better drainage but may compromise load strength. Choosing the proper configuration can be tricky and may need careful thought.

Furthermore, the finish of the galvanized steel can affect longevity. Some surfaces are more resistant to corrosion than others. It’s important to assess the expected environmental conditions. Mistakes can happen. A wrong choice based on superficial traits could lead to safety issues. Taking time to reflect on these factors is crucial for a successful project.

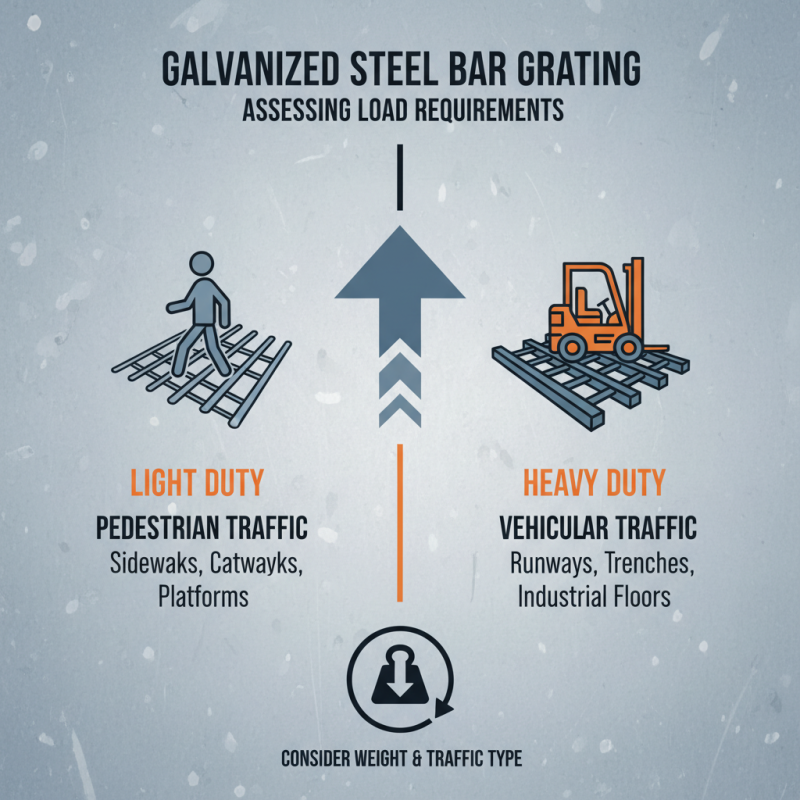

When assessing load requirements for galvanized steel bar grating, it’s crucial to consider the weight it will bear. Think about the type of traffic expected. Will it support pedestrian use or heavy machinery? This distinction significantly impacts the choice of grating design. For example, a light-duty grating may suffice for foot traffic, while a heavier option is needed for vehicles.

Load-bearing capacities are usually categorized. It is vital to identify these categories: light, medium, and heavy-duty. Each has specific load specifications. Standard ratings often provide reliable guidelines. However, every project may differ in its unique circumstances. It is essential to see how actual conditions align with these standards. Ignoring this can lead to failures. So, regularly re-evaluating assumptions can make a big difference.

Always consider environmental factors. Will your grating face corrosion, heavy rain, or snow? The local climate affects the durability of your choice. Often, projects underestimate weather impacts, leading to unexpected repairs. Proper calculations can prevent these pitfalls. Recognizing gaps in your planning process is key. Don’t rely solely on generic data; ensure the specifics match your project needs.

When choosing galvanized steel bar grating, understanding corrosion resistance is crucial. Galvanized steel undergoes a process that coats it with zinc. This protective layer helps resist rust and deterioration. However, not all galvanization processes are created equal. Factors such as the thickness of the zinc coating impact longevity significantly.

Consider exposure to environmental elements. High humidity or chemicals can accelerate corrosion. For areas prone to salt exposure, like coastal sites, enhanced coatings may be necessary. Regular maintenance checks are important, but how often should you conduct these? Many overlook this crucial step until damage appears.

Evaluate the quality of the grating before purchase. Look for ensure that the processing methods are reliable. Some manufacturers may cut corners, leading to thinner coatings. This can result in premature failure. Pay attention to industry standards, but also trust your instincts. If something seems off, dig deeper. Your project deserves the best materials.

| Dimension | Material | Coating Type | Corrosion Resistance Rating | Load Capacity (lbs) | Applications |

|---|---|---|---|---|---|

| 1" x 3" | Galvanized Steel | Hot-Dip Galvanized | Excellent | 800 | Walkways, Platforms |

| 2" x 4" | Galvanized Steel | Pre-Galvanized | Good | 1000 | Heavy Traffic Areas |

| 1.5" x 5" | Galvanized Steel | Zinc-Aluminum Coating | Very Good | 1200 | Industrial Applications |

| 3" x 3" | Galvanized Steel | Polymer Coating | Excellent | 1500 | Marine Environments |

Choosing the right bar spacing for galvanized steel bar grating is crucial. It impacts both drainage and structural integrity. Wider spacing can enhance water flow, reducing pooling. However, it might compromise load-bearing capacity. Finding the balance is essential.

When determining spacing, consider the specific needs of your project. A walkway might require closer spacing for safety. In contrast, a drain cover may benefit from wider gaps. Think about foot traffic and weight loads. Visualizing the environment helps clarify your choice.

Sometimes, the calculations might not align with practical needs. What looks good on paper may not work in reality. Regularly revisiting your spacing choices can lead to better decisions. Reflecting on past mistakes will guide you. Always prioritize both functionality and safety in your design.

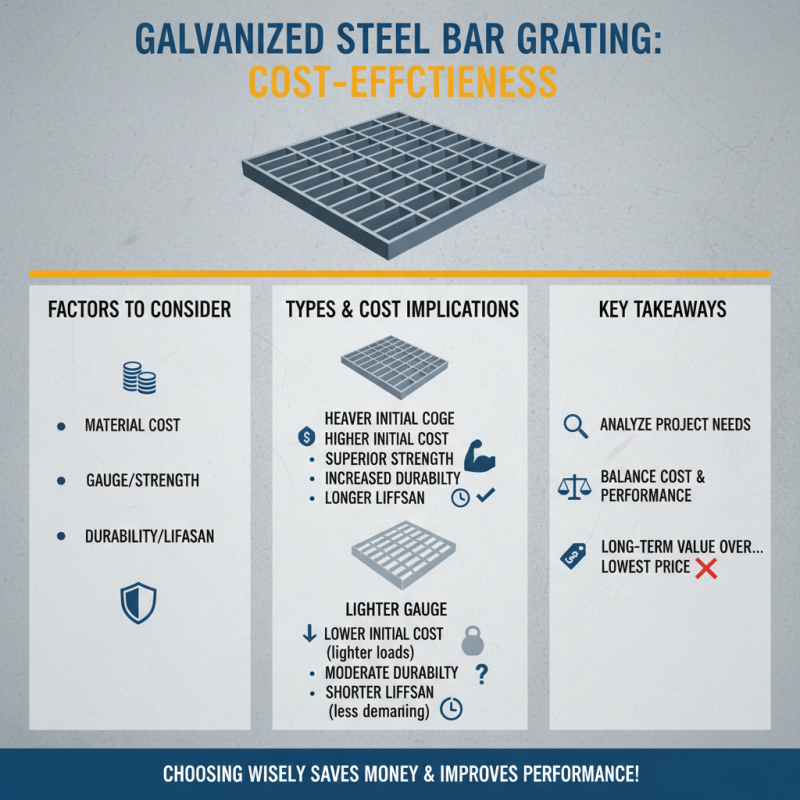

When considering galvanized steel bar grating for your project, cost-effectiveness plays a crucial role. Different types offer varying prices, so it's important to analyze your needs thoroughly. For instance, heavier gauge gratings typically carry a higher cost but provide better strength. Conversely, lighter options save money but may compromise durability.

Tip: Always calculate long-term costs, not just upfront prices. A cheaper grating might require more frequent replacements, leading to higher overall expenses.

It’s essential to think about the specific application. Industrial settings may demand sturdier gratings, while lighter options suffice for pedestrian walkways. Different dimensions also affect costs. Wider bars may yield higher initial investments but feature improved load-bearing capabilities.

Tip: Review installation expenses too. Complex setups could lead to increased labor costs. Balance your budget carefully. Keep in mind, the right choice should meet both functional and financial needs, even if it means spending a little extra upfront.