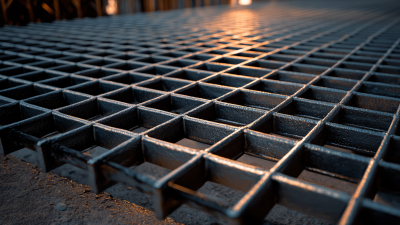

Choosing the right Bar Steel Grating for your construction projects is a critical decision that can significantly impact the safety, efficiency, and durability of your structures. In this ever-evolving industry, understanding the different types and applications of Bar Steel Grating is essential for successful project outcomes.

As noted by industry expert John Smith, "The right Bar Steel Grating not only enhances structural integrity but also provides a cost-effective solution for flooring, walkways, and drainage systems."

In 2025, with advancements in materials and technology, the options for Bar Steel Grating are more varied than ever. Engineers and construction managers must navigate a complex landscape of designs, load-bearing capacities, and environmental considerations. By making informed choices, professionals can ensure they select the most appropriate grating that meets the specific needs of their projects.

This article will delve into key factors to consider, including material selection, spacing requirements, and the specific applications of Bar Steel Grating within different construction environments. As the industry continues to grow, staying informed about innovations and best practices will empower builders to make the best choices for their projects.

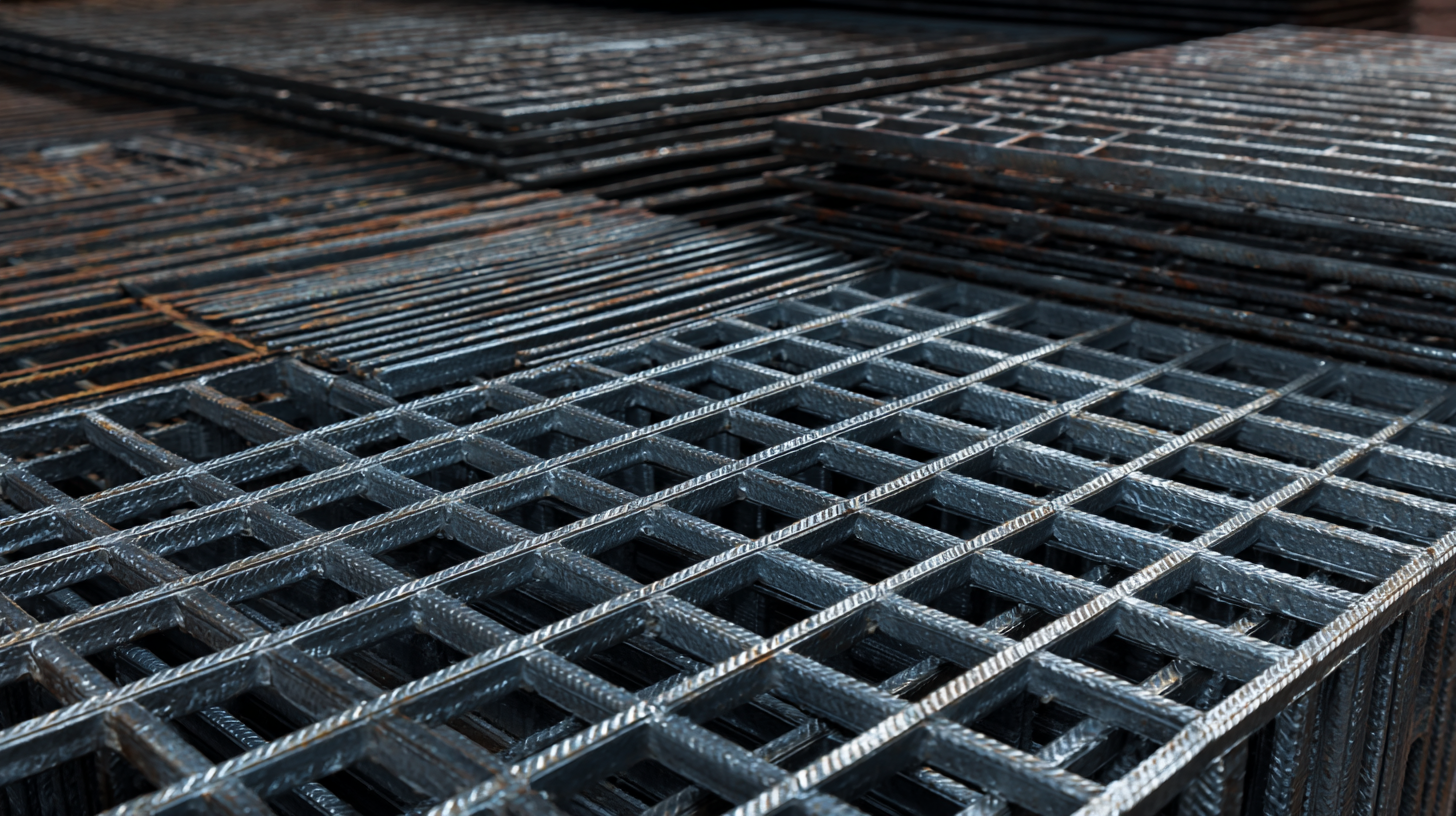

When selecting bar steel grating for your construction projects, there are several key factors to consider that can significantly impact both the performance and safety of your installations. First and foremost, the load-bearing capacity is critical. According to the "Steel Grating Institute," the right grating should withstand expected traffic loads, with common standards evaluating loads between 200 to 1,200 pounds per square foot. It's essential to align your choice with the specific requirements of your project, taking into account both static and dynamic loads.

Another crucial aspect is the material and surface finish of the grating. Hot-dipped galvanized steel is often preferred for outdoor environments due to its resistance to corrosion, while stainless steel is ideal for areas requiring high hygiene standards, such as food processing facilities. Reports from the "American Iron and Steel Institute" indicate that approximately 50% of steel structures utilize some form of grating, reinforcing the importance of selecting the right type for long-term durability.

Tips: Always check the product specifications and compliance with local safety codes. Conducting a site assessment before purchasing is also recommended to understand any unique environmental factors that may affect your choice of grating. Lastly, consult with manufacturers for tailored solutions that fit your project’s specific load and environmental requirements.

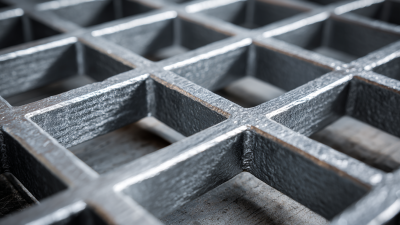

When selecting bar steel grating for construction projects, understanding the load-bearing capacities of various types is crucial. According to the American National Standards Institute (ANSI), the load-bearing capacity of bar grating is determined by factors such as the thickness of the bars, the spacing between them, and the type of material used—typically steel, aluminum, or fiberglass. For instance, heavy-duty steel grating can offer load capacities upwards of 1,200 pounds per square foot, making it ideal for applications in industrial environments where heavy machinery operates.

Furthermore, different configurations of bar steel grating, including welded and swaged styles, affect their load-bearing performance. A report from the Steel Grating Industry Association (SGIA) highlights that welded grating tends to provide superior strength compared to its swaged counterpart due to the method of construction. Welded gratings can distribute loads more evenly across their surface, making them suitable for demanding environments such as steel mills or refineries where safety and durability are paramount. Understanding these nuances helps ensure that the chosen grating not only meets the specific load requirements of a project but also complies with relevant safety standards.

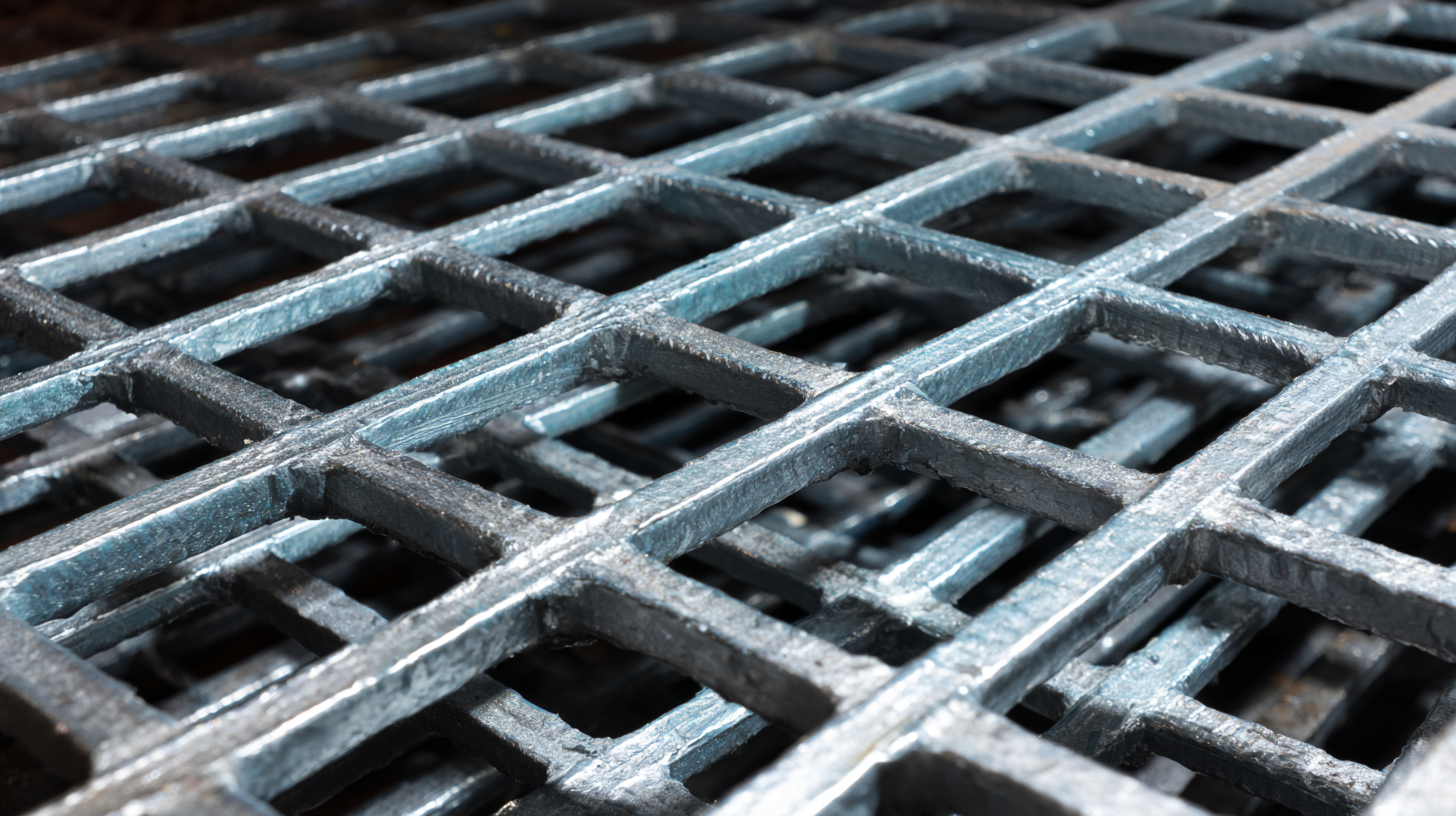

When selecting bar steel grating for construction projects, understanding the corrosion resistance of various industrial grating materials is paramount. According to a report by the American Institute of Steel Construction, corrosion-related failures account for approximately 60% of maintenance issues in industrial environments. This underscores the importance of not just material choice but also understanding how different materials perform in corrosive conditions.

Materials such as carbon steel can be economical, yet their vulnerability to corrosion may lead to higher long-term maintenance costs. In contrast, galvanized steel grating, which offers a protective zinc coating, can provide enhanced resistance, reportedly increasing the lifespan of grating by up to 50% in harsh environments, based on data from Corrosion Management Solutions. Additionally, stainless steel grating, with its inherent resistance to rust and corrosion, is often the preferred choice for applications exposed to moisture and chemicals, although it comes at a higher initial cost. The advantages of using more resilient materials can significantly reduce lifecycle expenses, making it a critical aspect of the decision-making process for construction professionals.

| Material Type | Corrosion Resistance Rating | Typical Applications | Cost per Square Foot ($) |

|---|---|---|---|

| Carbon Steel | Low | General Construction | $10 |

| Galvanized Steel | Medium | Industrial Flooring | $15 |

| Stainless Steel | High | Corrosive Environments | $25 |

| Aluminum | Medium | Lightweight Structures | $20 |

| Fiberglass Reinforced Plastic (FRP) | Very High | Chemical Plants | $30 |

When selecting bar steel grating for construction projects, understanding how bar spacing impacts safety and performance is crucial. According to the American National Standards Institute (ANSI), the spacing between bars can significantly affect load-bearing capacities and slip resistance, which are vital for ensuring the safety of workers and equipment. A tighter bar spacing can enhance stability while reducing the risk of falls; however, this may come at the cost of increased material and installation expenses.

Tip: Assess the anticipated foot traffic and load requirements for your project. For high-traffic areas, it is advisable to choose bar grating with closer spacing to prevent slips and enhance support.

Moreover, studies have shown that a well-designed grating system can contribute to overall workplace safety. The Occupational Safety and Health Administration (OSHA) emphasizes that maintaining proper spacing between bars can mitigate trip hazards. It’s equally important to consider the materials used in grating, as certain coatings can provide additional slip resistance.

Tip: Always review local building codes and safety regulations. This ensures your grating installations comply with the necessary standards and optimizes performance for specific applications.

When evaluating the cost-benefit of steel grating versus alternative materials for construction projects, it's essential to consider both immediate and long-term impacts. Steel grating offers unmatched durability and strength, making it a preferred choice for many industrial applications. Its resistance to extreme conditions ensures longevity, reducing the frequency of replacements. However, with rising commodity prices, budget constraints can steer businesses towards more economical options, such as fiber-reinforced polymer (FRP) grating, which has shown significant growth in recent market analyses.

Moreover, the move towards sustainable materials is gaining momentum. Experts highlight the benefits of non-toxic materials, such as those derived from recycled and eco-friendly sources. For instance, the innovative use of galvanized steel gratings in various applications suggests a shift towards both functionality and environmental consciousness in material selection. By weighing these factors, construction professionals can make informed decisions that align with budgetary limits while ensuring safety and sustainability in their projects.