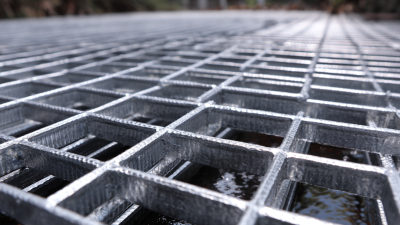

Choosing the right materials for your project is vital. One option that stands out is Hot Dipped Steel Grating. This type of grating offers durability and strength. It is commonly used in industrial settings. You might find it in walkways, platforms, and drainage covers.

Hot Dipped Steel Grating provides excellent corrosion resistance. The galvanizing process enhances its lifespan. However, not all projects will benefit from its use. Consider the specific load requirements and environmental factors. Ask yourself if the cost aligns with your budget. It’s important to weigh the pros and cons.

Look for reliable suppliers when purchasing. Examine the grating dimensions and load ratings. The details matter significantly. If you overlook them, you may face issues later. Hot Dipped Steel Grating can be an excellent choice if chosen wisely. Reflect on its applications and practicality for your needs.

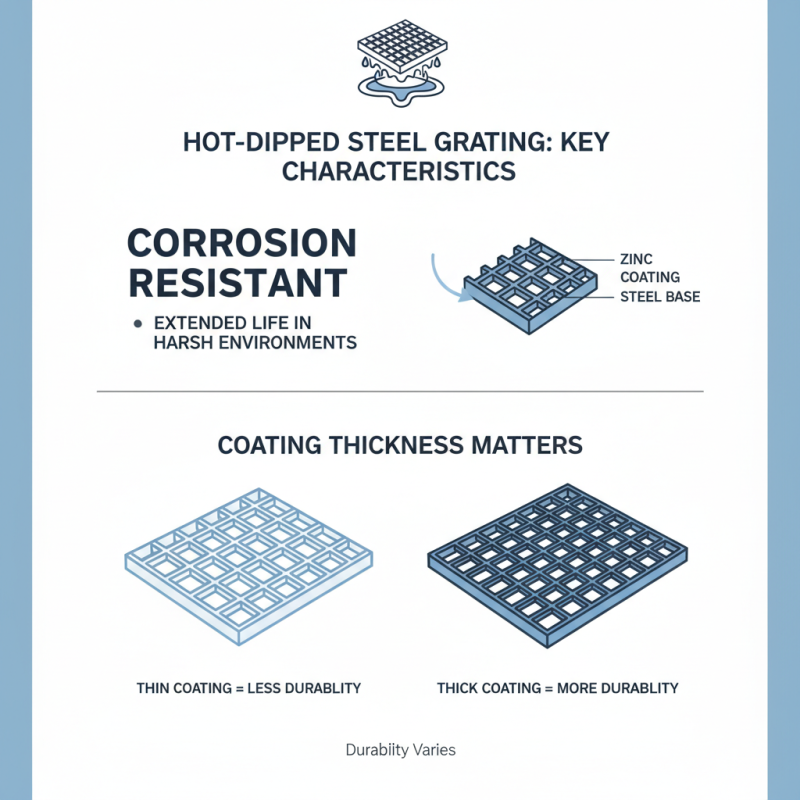

When selecting hot-dipped steel grating, understanding its characteristics is crucial. Hot-dipped steel grating is known for its strong resistance to corrosion. This property comes from the zinc coating applied during the manufacturing process. Such grating can last longer in harsh environments. However, not all coatings are the same; thickness can vary. This variation affects durability.

Another important characteristic is load capacity. Steel grating can support different weights depending on its design. It’s essential to assess the specific needs of your project before making a choice. Think about foot traffic or heavy equipment. The wrong choice could lead to failures, causing safety issues. Remember, not every type is suitable for outdoor use. Some may rust faster than others.

Aesthetics also play a role. While functionality is primary, the appearance of grating matters in certain projects. Visual appeal can enhance a space but can compromise some properties. It’s a balancing act. Consider these factors carefully. Each decision shapes the overall outcome of the project. Reflect on what qualities matter most to you.

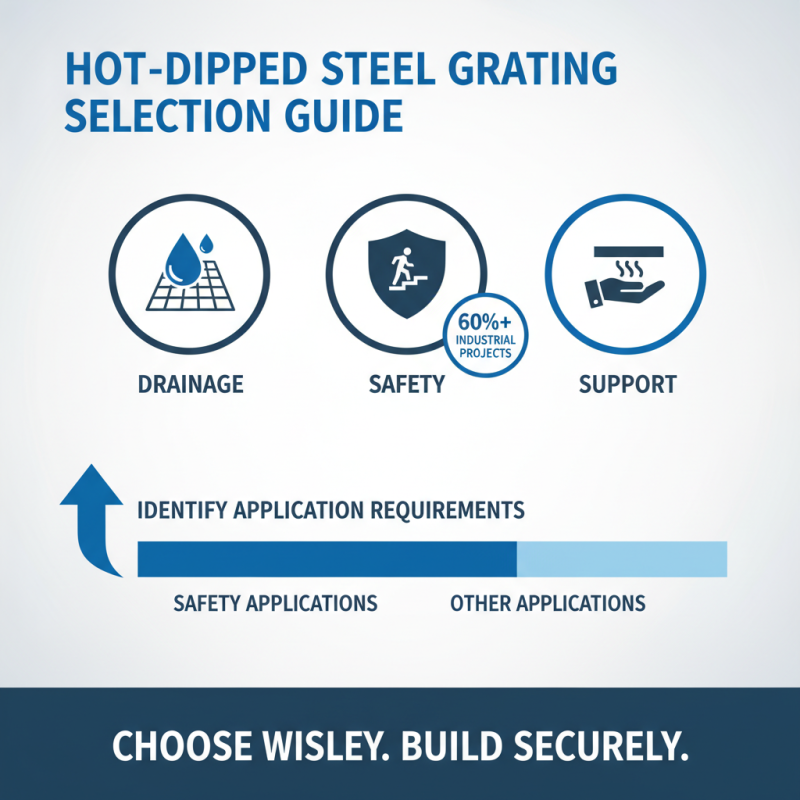

When selecting hot dipped steel grating for a project, identifying application requirements is crucial. Steel grating serves various purposes, such as drainage, safety, and support. According to a recent industry report, over 60% of industrial projects utilize steel grating primarily for safety applications. This highlights the importance of assessing your specific needs.

The load-bearing capacity is a key factor. Projects requiring heavy traffic need grating that can support significant weights. A report from the American National Standards Institute indicates that specific loading criteria must be met, depending on the application. For instance, grating used in roadways must withstand loads exceeding 1,500 pounds per square foot. Additionally, environmental factors like corrosion resistance are vital. Hot dipped galvanizing offers superior protection in harsh conditions, but not all projects demand this level of resilience.

It's essential to reflect on long-term maintenance. Choosing low-quality grating might save money upfront but lead to higher costs later due to frequent replacements. Over 40% of project managers report issues with premature deterioration of materials. Rethinking the selection process can prevent these pitfalls. Evaluating both immediate and future needs will help ensure the right choice in steel grating.

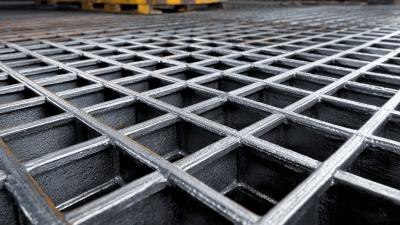

When evaluating hot-dipped steel grating, consider different types and designs. Common types include welded, press-locked, and swaged. Each offers unique benefits. A recent industry report noted that welded grating has a higher load capacity, making it ideal for heavy machinery. On the other hand, press-locked grating is suitable for pedestrian traffic. Understanding your project's needs is essential.

Design is just as critical. The spacing between bars affects both load distribution and debris flow. According to studies, tighter spacing can reduce the risk of slips and falls. However, this can also lead to a higher cost. A medium spacing often provides a balance between safety and affordability.

Functionality should guide your choice. Hot-dipped coatings offer corrosion resistance, extending the lifespan of the grating. However, color options are limited, which may not align with aesthetic goals. Some industries report needing more standardized sizes, but custom fabrication increases lead time. Reflecting on these aspects can lead you to a more informed decision.

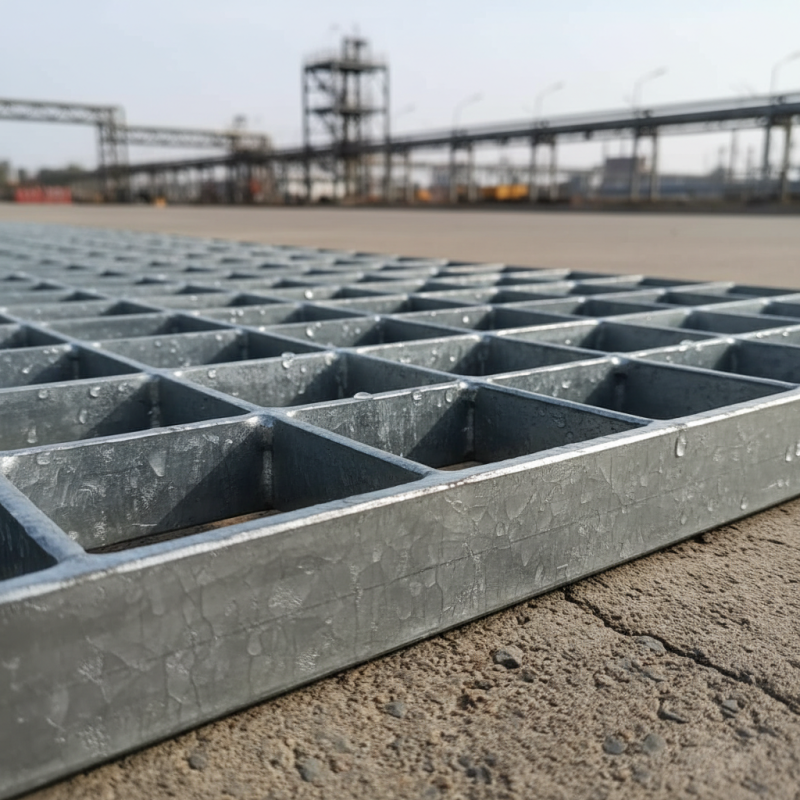

When selecting hot dipped steel grating, durability and corrosion resistance are crucial factors. Steel grating is often exposed to harsh environments. It needs to withstand weather elements, chemicals, and mechanical stress. Hot dipped galvanizing offers a protective layer that significantly enhances longevity. This process involves immersing steel in molten zinc. The result is a strong bond that resists rust.

Corrosion can severely impact performance. Some projects may require grating in coastal areas. Here, saltwater exposure is common. In such cases, choosing high-quality grating can be vital. Ensuring adequate thickness of the galvanized layer is important. A thinner layer may lead to quicker deterioration.

Additionally, users should consider the grating’s load-bearing capacity. Sometimes, opting for a heavier gauge can improve both durability and safety. However, this may not always be cost-effective. Evaluating the environment and usage will lead to better choices. Keep in mind that not all steel gratings are created equal. Each project has unique demands that must be addressed carefully.

Choosing the right specifications and standards for hot dipped steel grating is crucial for project success. The American National Standards Institute (ANSI) establishes guidelines. These guidelines can determine the durability of the grating under load. For example, steel grating is often assessed based on its load-bearing capacity. Reports show that properly specified steel grating can withstand loads exceeding 1,000 pounds per square foot.

Material thickness is a significant specification to consider. Thicker materials can offer better resistance to bending and deformation. An industry report suggests that grating with a thickness of 1 inch can outperform thinner alternatives in high-traffic areas. However, thicker grating may come with higher costs and added weight. It's essential to balance these factors according to your project’s budget.

You should also pay attention to other dimensions, like the spacing between bars. Commonly, a spacing of 1 inch to 3 inches is advised. This factor can influence safety and stability. Narrower spacing can reduce tripping hazards, while wider spacing can allow for better drainage. It is often overlooked, but proper spacing can enhance both safety and longevity of the grating. Choosing the right specifications is not just about selecting materials; it requires thoughtful consideration of project-specific conditions.