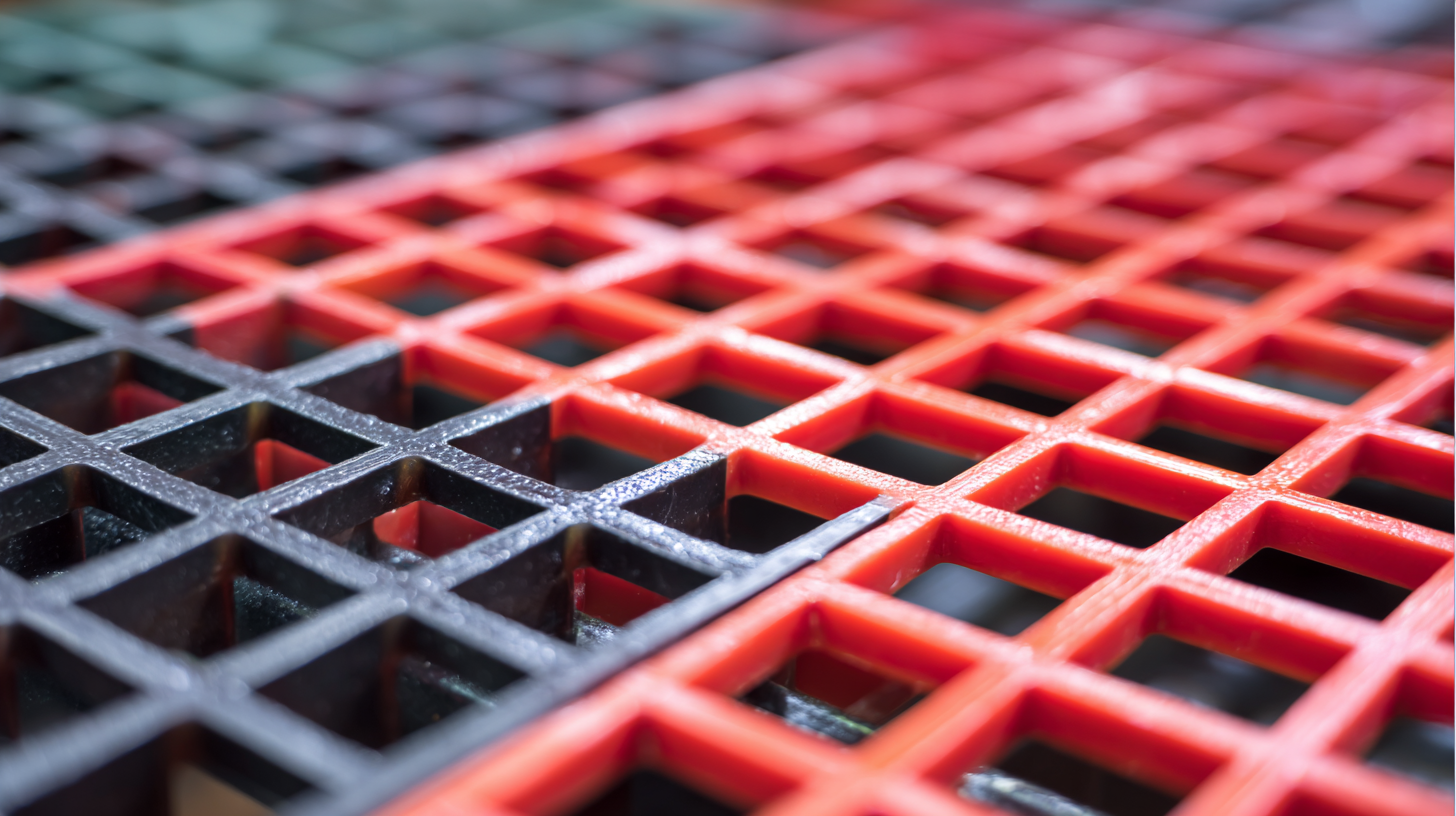

In today's industrial landscape, the selection of suitable materials is crucial for optimizing both efficiency and safety in various applications. One such essential material is Plastic Floor Grating, which has gained significant traction due to its lightweight, corrosion-resistant, and durable properties. As we explore the 2025 technological trends, it's imperative to understand how advancements in manufacturing techniques and materials can influence our choices.

This blog will guide you through the considerations for choosing the best Plastic Floor Grating tailored to your specific industrial needs. By examining factors such as load-bearing capacity, environmental resistance, and ease of installation, we aim to equip you with the knowledge to make informed decisions in an ever-evolving market. Whether you're upgrading an existing facility or planning a new project, understanding the latest innovations in Plastic Floor Grating can pave the way for safer, more efficient operations.

In today's industrial landscape, the selection of suitable materials is crucial for optimizing both efficiency and safety in various applications. One such essential material is Plastic Floor Grating, which has gained significant traction due to its lightweight, corrosion-resistant, and durable properties. As we explore the 2025 technological trends, it's imperative to understand how advancements in manufacturing techniques and materials can influence our choices.

This blog will guide you through the considerations for choosing the best Plastic Floor Grating tailored to your specific industrial needs. By examining factors such as load-bearing capacity, environmental resistance, and ease of installation, we aim to equip you with the knowledge to make informed decisions in an ever-evolving market. Whether you're upgrading an existing facility or planning a new project, understanding the latest innovations in Plastic Floor Grating can pave the way for safer, more efficient operations.

When selecting plastic floor grating for industrial environments, several common issues deserve consideration. One significant problem is the potential for chemical degradation. Many industrial settings involve exposure to harsh chemicals that can break down certain types of plastic. It is crucial to choose grating made from materials that are chemically resistant to the specific substances encountered in your facility. Polypropylene and fiberglass-reinforced plastic often provide better durability against corrosive elements compared to standard PVC.

Another issue is the load-bearing capacity of plastic grating. In environments where heavy machinery operates or substantial foot traffic is expected, choosing the right type of grating is essential. Not all plastic gratings can withstand significant weight, which could lead to structural failures or safety hazards. It's advisable to consult load capacity specifications and, if necessary, seek out reinforced options designed to handle heavy loads. Additionally, the installation of proper drainage solutions in conjunction with the right type of plastic grating can mitigate the risks associated with water pooling, further enhancing safety and functionality in industrial spaces.

| Grating Type | Material | Load Capacity (lbs) | Typical Applications | Common Issues |

|---|---|---|---|---|

| Type 1 | PVC | 1000 | Chemical plants, Warehouses | Can warp in extreme heat |

| Type 2 | Polypropylene | 750 | Food processing, Cleanrooms | Limited resistance to abrasive materials |

| Type 3 | Fiberglass | 1500 | Heavy machinery areas, Outdoor applications | Higher cost compared to other materials |

| Type 4 | Reinforced Nylon | 800 | Automotive, Electronics | May be susceptible to UV degradation |

| Type 5 | ABS Plastic | 600 | Retail, Warehousing | Not suitable for high-temperature applications |

When selecting the best plastic floor grating for industrial applications, understanding the

load-bearing capabilities of different grating types is crucial.

Different environments and usage requirements influence the choice of grating materials. For instance, some plastic gratings

are designed to withstand heavy loads, making them ideal for industrial

settings where machinery or heavy equipment is frequently used. It's essential to assess not only the static load capacity

but also dynamic loads that may occur during operations.

When selecting the best plastic floor grating for industrial applications, understanding the

load-bearing capabilities of different grating types is crucial.

Different environments and usage requirements influence the choice of grating materials. For instance, some plastic gratings

are designed to withstand heavy loads, making them ideal for industrial

settings where machinery or heavy equipment is frequently used. It's essential to assess not only the static load capacity

but also dynamic loads that may occur during operations.

Tips for Choosing Grating:

When selecting plastic floor grating for industrial applications, evaluating chemical resistance is crucial. Plastic grating materials such as fiberglass reinforced plastic (FRP) and polyvinyl chloride (PVC) exhibit varying degrees of resistance to different chemicals. A recent study by the American Chemical Society highlights that FRP can withstand harsh solvents and acids, making it ideal for environments exposed to aggressive chemicals. Conversely, PVC offers excellent resistance to mild acids and bases, but it may degrade when exposed to strong oxidizing agents. This variance necessitates thorough testing to ensure the chosen material meets the specific chemical exposure levels of your industry.

Tip: Before finalizing your choice, obtain Material Safety Data Sheets (MSDS) for the chemicals used in your facility. Compare these with chemical resistance charts provided by grating manufacturers to identify compatible materials.

Understanding the impact of temperature on chemical resistance is also essential. According to a report from the Society of Plastics Engineers, materials can lose their integrity and resistance under fluctuating temperature conditions. Ensuring that your chosen plastic grating can operate effectively within the temperature range of your environment will extend its lifespan and maintain safety standards.

Tip: Conduct a site assessment to monitor temperature variations to better inform your selection process.

When selecting plastic floor grating for industrial environments, slip resistance should be a primary consideration. Industrial settings often involve moisture, spills, and various substances that can increase the risk of slips and falls. Therefore, look for grating options that have textured surfaces or specialized coatings designed to enhance traction, ensuring safety for personnel moving throughout the space. Additionally, consider the spacing and design of the grating itself; features that prevent the accumulation of debris can further improve safety and reduce the likelihood of slipping.

In parallel to enhancing safety in industrial settings, protective gear is essential when working with tools that pose a risk of injury. Just as the right plastic floor grating can prevent accidents from slips, using cut-resistant gloves while handling sharp tools can protect users from cuts and punctures. Whether you're handling a mandoline or preparing food with a knife, the right protective equipment can provide peace of mind and safeguard your hands, allowing you to focus on your tasks without the fear of injury. Investing in both quality floor grating and appropriate safety gear reflects a commitment to maintaining a safe working environment.

When it comes to industrial plastic grating, proper maintenance is crucial to ensure longevity and functionality. According to a report by IBISWorld, the industrial flooring market is expected to grow by 4.3% annually, emphasizing the need for effective maintenance strategies. Industrial environments can be harsh, leading to wear and tear on grating materials. Regular inspections and timely repairs can prevent costly downtime and enhance safety.

One effective tip for maintaining plastic floor grating is to establish a cleaning schedule. Regularly removing debris and contaminants can enhance traction and lifespan. For instance, a study by the National Floor Safety Institute found that well-maintained surfaces can reduce slip-and-fall accidents by up to 80%. Additionally, consider using non-corrosive cleaning agents to prolong the durability of your grating.

Another challenge in industrial settings is UV degradation, particularly for outdoor applications. To combat this, selecting UV-resistant plastic grating can significantly reduce maintenance frequency. Reports suggest that using high-density polyethylene (HDPE) can enhance the product's lifespan, making it a cost-effective solution for businesses. Always consult with suppliers to ensure you’re investing in high-quality materials that meet the specific demands of your industrial environment.