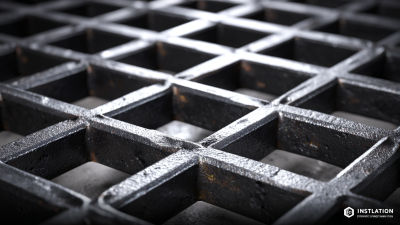

In the world of industrial applications, choosing the right materials can significantly impact safety, efficiency, and durability. Among the many options available, Serrated Steel Grating stands out for its unique design and functional benefits. This type of grating, characterized by its serrated surface, provides enhanced traction, making it ideal for environments prone to spillages or heavy foot traffic.

As industries evolve, the need for tailored solutions becomes paramount, and understanding the various factors to consider when selecting Serrated Steel Grating can help you meet your specific operational requirements. This blog will explore the best practices for choosing the most suitable Serrated Steel Grating, ensuring that your industrial operations run smoothly and effectively.

Whether you’re in construction, manufacturing, or any sector that requires robust flooring solutions, making the right choice will enhance safety and productivity in your workplace.

When selecting the right serrated steel grating for industrial applications, understanding the various types available in the market is crucial. Serrated steel gratings are primarily categorized by their manufacturing methods and materials, impacting their strength, durability, and application suitability. Notably, the growing demand in the steel market signifies an opportunity for advancements in grating products. According to a market research study, the global steel market size is projected to reach USD 1.92 trillion by 2030, with a CAGR of 4.6% from 2024, highlighting the increasing reliance on metallic infrastructure in industrial sectors.

In addition, the global market for carbon steel, integral to serrated grating production, is on a similar growth trajectory. Expected to expand from USD 1.14 trillion in 2025 to USD 1.69 trillion by 2035 at a CAGR of 4%, this trend underscores the rising demand for stronger and more resilient steel products. With the evolution of cutting-edge manufacturing technologies and a heightened focus on safety standards, industries are encouraged to consider these growth patterns when choosing serrated steel gratings that best meet their operational needs.

When selecting serrated steel grating for your facility, there are several key factors to consider to ensure optimal performance and safety. First, assess the environment where the grating will be installed. For outdoor applications exposed to weather conditions, corrosion resistance is crucial. Look for coatings or treatments that enhance durability, such as hot-dip galvanizing, which helps to protect against rust and extends the life of the grating.

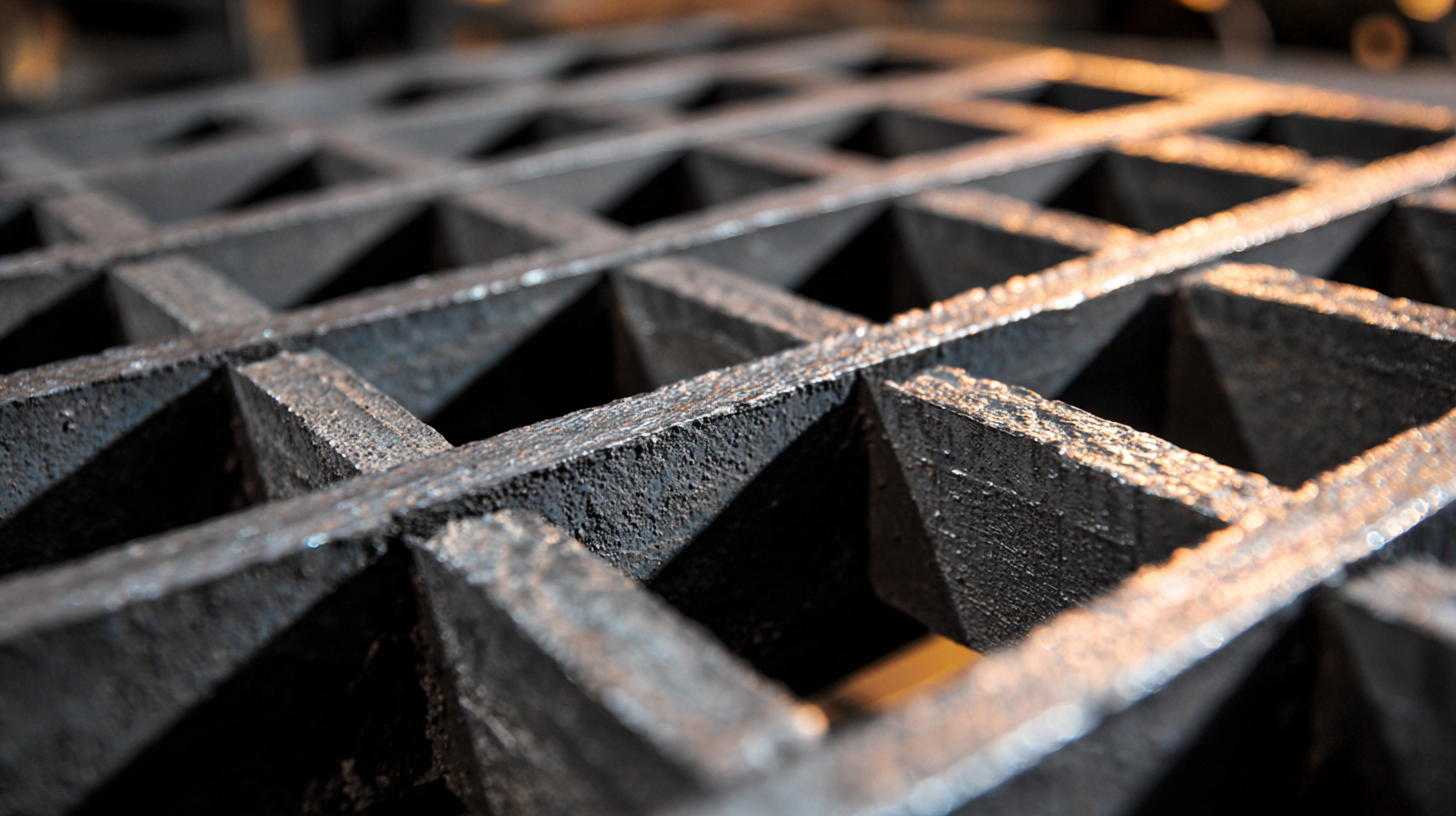

Another important consideration is the load capacity required for your specific application. Evaluating the expected weight and traffic that the grating will endure is essential to choose the appropriate thickness and bar spacing. Additionally, consider the depth of the serration, which can affect traction and slip resistance. Safety is paramount in industrial settings, so selecting the right profile not only promotes safer walking surfaces but also minimizes the risk of accidents. By taking these factors into account, you can choose a serrated steel grating that meets your facility’s unique requirements effectively.

Serrated steel grating has gained significant popularity in industrial applications, primarily due to its enhanced safety and durability compared to traditional grating options. One of the key advantages of serrated grating is its superior slip resistance, which is crucial in environments where spills or moisture are common. The unique design of serrated edges creates a more secure footing, significantly reducing the risk of accidents. This makes serrated steel grating an ideal choice for walkways, platforms, and equipment access areas.

When selecting serrated steel grating for your needs, consider the following tips:

By choosing serrated steel grating, you not only enhance workplace safety but also invest in a long-lasting solution that outperforms traditional grating materials. Its robust design caters specifically to industrial environments, making it a smart, efficient decision for any facility looking to optimize safety and functionality.

When selecting serrated steel grating for industrial applications, evaluating its load-bearing capacity is crucial to ensure structural integrity and safety. According to industry standards, serrated steel grating is engineered to withstand specific load requirements based on the intended use, whether it be for walkways, platforms, or mezzanines. For instance, many manufacturers adhere to guidelines established by the American National Standards Institute (ANSI), which outline loading capacities depending on the spacing and thickness of the grating.

In practice, the load-bearing capacity of serrated steel grating can vary significantly based on the material composition, design configuration, and exposure conditions. A detailed analysis shows that heavy-duty load scenarios can require gratings capable of supporting up to 1,000 pounds per square foot, making it essential for users in industries like mining and construction to choose the right type of grating. Specific load scenarios commonly found in industrial settings, such as concentrated loads and dynamic forces, should also be taken into consideration to ensure optimal performance and compliance with safety standards.

Ultimately, a well-chosen serrated steel grating not only enhances safety by preventing slips and falls but also contributes to the overall efficiency and longevity of infrastructure. Proper assessment of load requirements, coupled with expert installation practices, will ensure that the grating functions under the anticipated loads and environmental conditions over its lifespan.

Maintaining serrated steel grating is crucial for ensuring its longevity and structural integrity in industrial applications. Regular inspections are essential to identify any signs of wear or damage. According to a report by the National Association of Architectural Metal Manufacturers, properly maintained grating can last up to 30 years, whereas neglecting maintenance can reduce its lifespan significantly. Simple practices, such as removing debris and cleaning the surface regularly, can prevent corrosion and ensure optimal performance.

Additionally, implementing a protective coating can further extend the life of serrated steel grating. The Steel Framing Alliance recommends using hot-dip galvanization, which not only enhances resistance to rust but also improves the aesthetic appeal of the grating. In environments exposed to harsh chemicals, a more specialized coating may be necessary. Adhering to these maintenance best practices can save companies substantial amounts on replacements and repairs, ultimately leading to more efficient operations in a demanding industrial landscape.