Choosing the right material for your project is crucial. Plain Steel Grating is a popular option in various applications. It offers durability and strength, making it suitable for industries like construction and manufacturing. But, how do you select the best type of plain steel grating?

First, consider the specific requirements of your project. For example, how much weight will the grating support? What kind of environmental conditions will it face? Plain Steel Grating comes in different sizes and load ratings. This variety can make your decision overwhelming. Some options may not be as strong as you need. Reflect on potential shortcomings before making a choice.

Next, think about installation and maintenance. Plain Steel Grating can be relatively easy to install. However, some types may require periodic cleaning or treatment to prevent rust. Be aware of these details. Ultimately, selecting the right plain steel grating involves careful consideration. Your final decision should align with both functionality and durability.

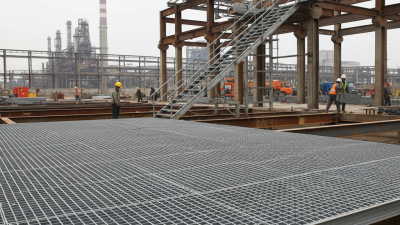

Plain steel grating is widely used across various industries. It provides a sturdy solution for flooring, walkways, and ventilation. Its applications can be seen in construction, manufacturing, and even transportation sectors.

In construction, plain steel grating often supports heavy loads. According to industry reports, it can bear loads of up to 1,000 pounds per square foot. This makes it highly suitable for industrial environments. However, it must be maintained regularly to prevent rust and deterioration. Without proper care, the longevity of the grating can be compromised, leading to safety issues.

In manufacturing facilities, plain steel grating aids in drainage and airflow. It allows fluid runoff, reducing the risk of hazardous spills. OSHA estimates that proper drainage can decrease workplace accidents by 25%. Yet, the design may not always suit every environment. Factors such as chemical exposure can weaken the material, so careful consideration is essential.

These points highlight the importance of understanding the specifics of your project's needs when selecting plain steel grating.

Choosing the right plain steel grating for your project requires careful consideration of several factors. One crucial aspect is the intended use. Is it for industrial flooring, walkways, or safety barriers? Each application has different load requirements. For example, heavy machinery areas need stronger grating than pedestrian walkways.

Another important factor is the spacing of the bars. Closer spacing can enhance safety but may increase cost. It’s vital to find a balance that meets safety standards without exceeding budget constraints. Durability is also key to consider. Steel grating needs to withstand environmental conditions. Corrosion resistance can be important, especially in humid or coastal areas.

Don't forget to reflect on installation. Heavy grating can be cumbersome to handle. Planning for the right tools and manpower is essential. Sometimes, you may realize that what seemed like the perfect choice doesn’t fit during installation. It's crucial to reassess your options and adapt when needed. Keep these factors in mind to make an informed decision.

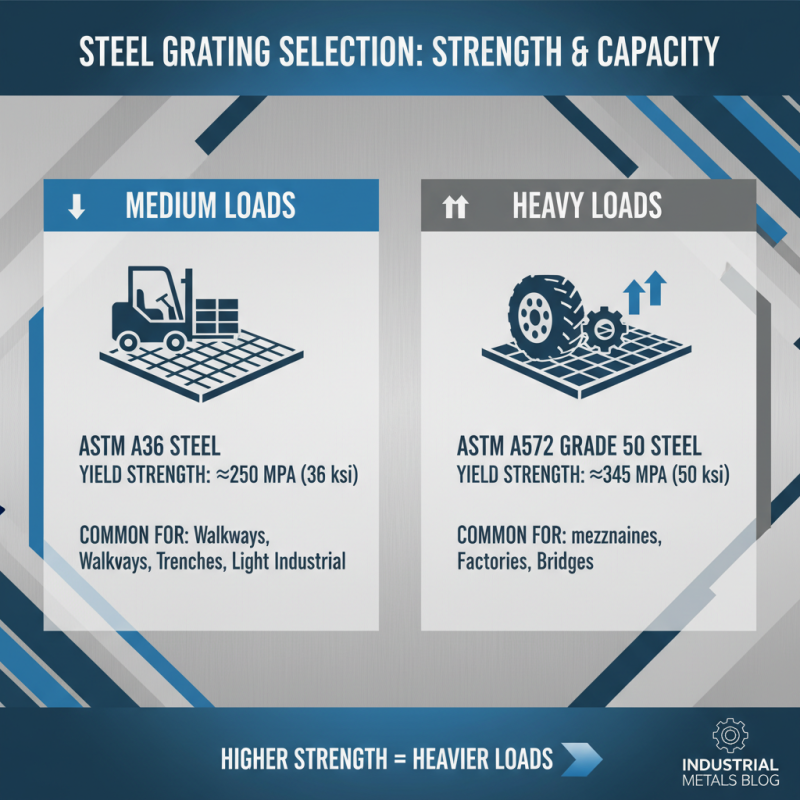

When selecting plain steel grating, understanding material strength and load capacity is crucial. Various steel grades exhibit different tensile strengths. For instance, ASTM A36 steel has a yield strength of around 250 MPa, making it suitable for medium load applications. On the other hand, ASTM A572 Grade 50 offers a higher yield strength of 345 MPa. The selection largely depends on intended use, where higher strength is essential for heavy loads.

Grating load capacity is determined by the spans and load specifications. For instance, a grating with a 30mm bar spacing can support larger loads compared to a 20mm spacing. According to industry data, a properly engineered grating can handle up to 1,200 pounds per square foot. However, overloading can lead to structural failure, which is a critical concern.

Tips: Always verify load requirements before purchase. Consider the grating's placement and environment. Regular inspections are vital to detect any fatigue or wear. If there is uncertainty in load expectations, opting for a higher-grade steel can provide peace of mind. Remember, safety should never be compromised for cost.

When selecting plain steel grating, cost-effectiveness and durability are key factors. Steel grating is often chosen for its strength and resilience. It can handle heavy loads and withstand harsh conditions. This makes it a practical option for various projects.

Cost is another important consideration. Plain steel grating can be affordable in large quantities. However, cheap options may compromise quality. Thin grating may bend or warp over time. It's essential to strike a balance between price and performance. Durability often reflects a higher upfront investment.

In reality, not all projects require the strongest materials. Sometimes, a lighter option suffices. Reflecting on your specific needs can yield better choices. Consider the environment and load demands before making a decision. This approach can lead to long-term savings and satisfaction. Choosing wisely today minimizes future headaches.

| Dimension | Load Capacity (lbs) | Weight (lbs/sq ft) | Cost ($/sq ft) | Durability Rating (Years) |

|---|---|---|---|---|

| 24" x 36" | 1000 | 5.0 | 50 | 10 |

| 36" x 48" | 1500 | 7.5 | 70 | 12 |

| 48" x 96" | 2000 | 8.5 | 90 | 15 |

| 60" x 120" | 2500 | 10.0 | 110 | 20 |

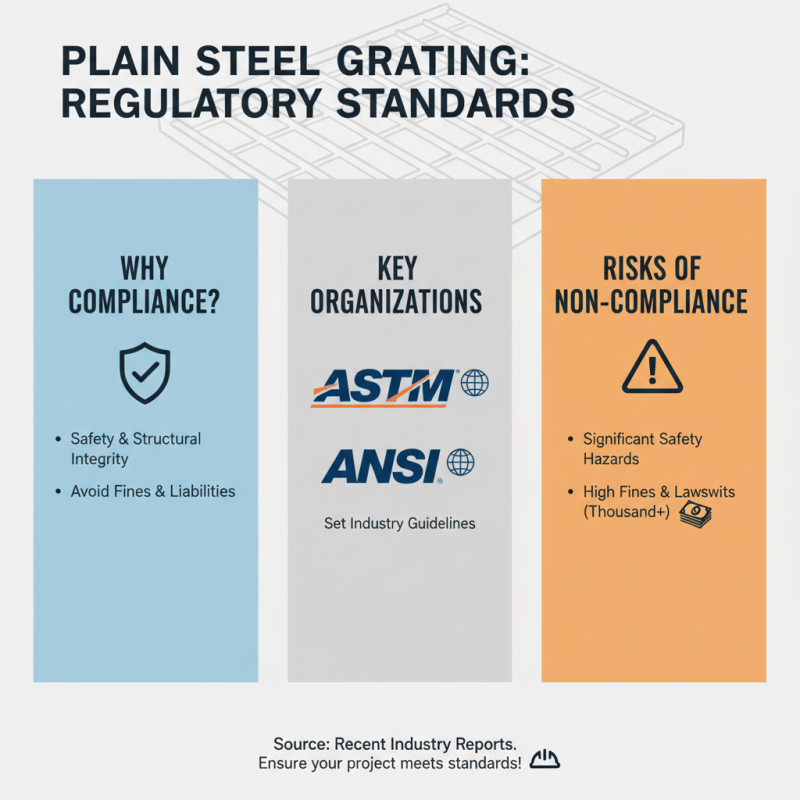

When selecting plain steel grating for construction, understanding regulatory standards is essential. These standards ensure safety and structural integrity. In many regions, grating must comply with guidelines set by organizations such as ASTM and ANSI. According to recent reports, non-compliance can lead to significant safety hazards, costing companies thousands in fines and liabilities.

Material specifications are critical. Plain steel grating often needs to meet specific load-bearing criteria. For instance, certain projects may require grating that supports 1000 pounds or more. Furthermore, factors like corrosion resistance should not be overlooked. Steel typically requires surface treatments, such as galvanizing, to enhance longevity. Inadequate attention to these details can lead to premature failures.

Many projects underestimate the compliance verification process. A survey found that 30% of construction companies reported challenges in meeting regulatory requirements. This highlights the need for careful planning and due diligence. Compliance often entails bureaucratic hurdles but ultimately protects both workers and investments. Understanding these regulations is essential for any successful construction project.