Choosing the right galvanized steel grating is crucial for various applications. This material offers strength, durability, and resistance to corrosion. However, many factors influence your choice. It’s essential to consider the load capacity, spacing, and environment where the grating will be installed.

Different projects require different types of galvanized steel grating. For instance, heavy industrial use may require thicker bars and closer spacing. In contrast, lighter applications might allow for a more economical design. Think about the specific needs of your project. What works for one situation may not fit another.

Don’t overlook the potential challenges in selecting galvanized steel grating. Some products may have hidden weaknesses. Adopting a thoughtful approach ensures that the grating meets your project requirements. Inspecting quality and speaking with suppliers can clarify your options. The right choice will enhance safety and efficiency for years to come.

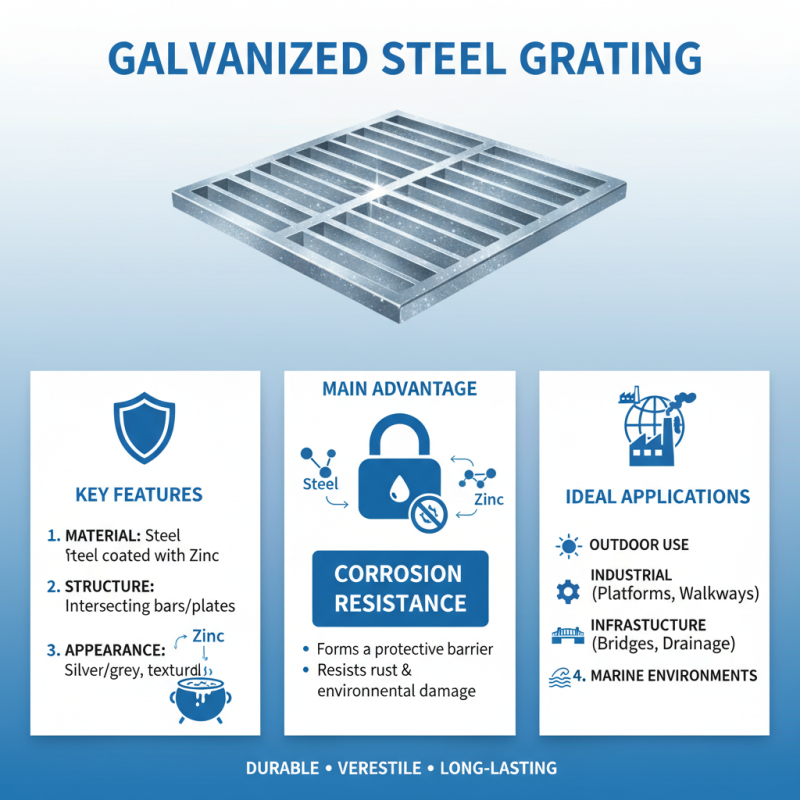

Galvanized steel grating is commonly used in various applications. It is essential to understand its basic features before making a selection. The main advantage of galvanized steel is its corrosion resistance. The galvanization process involves coating the steel with zinc, creating a protective barrier. This makes it ideal for outdoor use in various environments.

When choosing galvanized steel grating, you should consider its load-bearing capacity. Different types of grating can support different weights. It’s crucial to assess the expected traffic and any potential impacts. The spacing between the bars is another important factor. Wider spacing may allow for larger debris to fall through, while smaller spacing can provide a more stable surface but may trap materials.

You will also need to reflect on the aesthetic aspect. Galvanized grating typically has a rugged look, which may not suit all projects. Some might prefer a cleaner finish. Additionally, it is important to think about installation ease. Some grating types can be cumbersome to fit into place. Understanding all these elements will help ensure you select the right grating for your specific needs.

When selecting galvanized steel grating, identifying your project requirements is essential. Start by assessing the load capacity you need. Different applications demand varying strength levels. For example, walkways may require less load-bearing capacity than industrial platforms. Consider foot traffic, machinery weight, and environmental conditions.

Next, think about the spacing between the bars. This affects safety and accessibility. Closer bar spacing can prevent small items from falling through. However, larger gaps may be beneficial for drainage in wet locations. It's a trade-off that must align with your specific environment and safety needs.

Lastly, evaluate the surface finish. Smooth surfaces can be slippery, while gritted options enhance traction. What’s best for your project? Don't ignore aesthetics if they matter. Some projects might prioritize appearance over functionality. It's crucial to reflect on these choices carefully. The right grating is a blend of functionality, safety, and design.

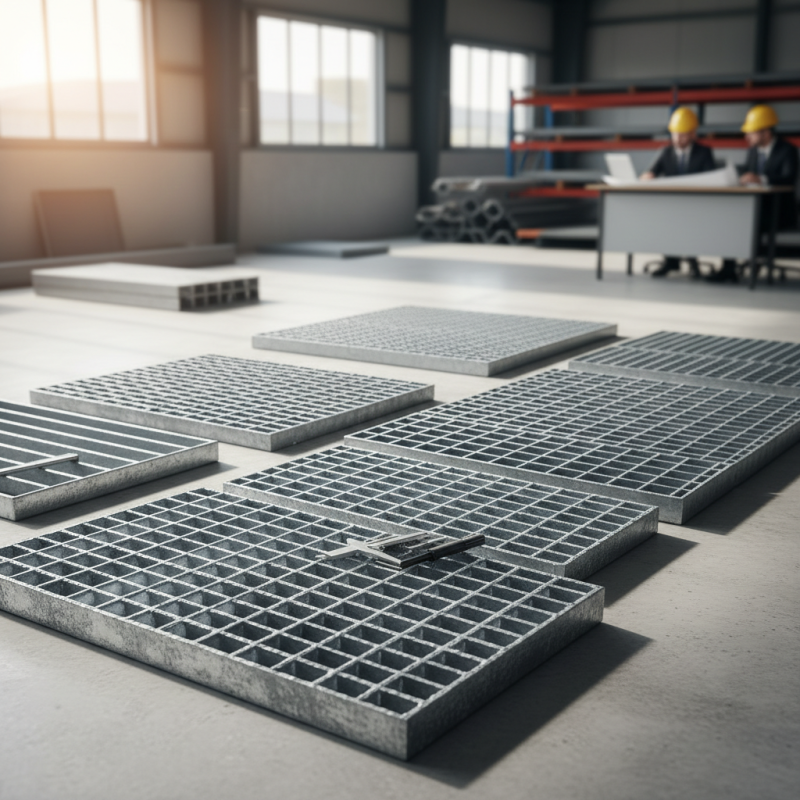

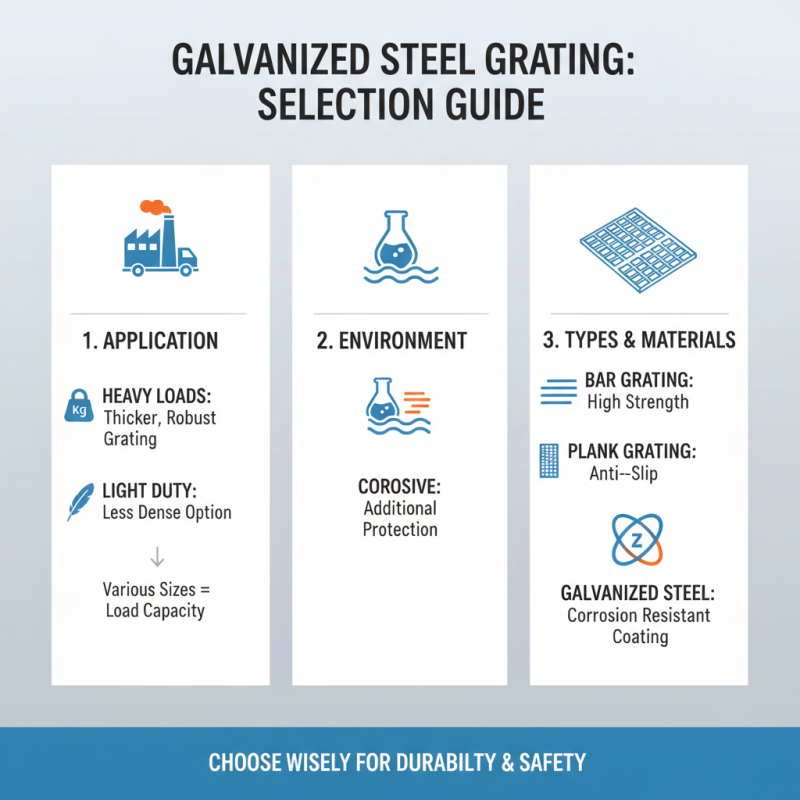

When evaluating different types of galvanized steel grating, begin by considering the material's application. For heavy loads, choose a thicker and more robust grating type. Light-duty applications might require a less dense option. Both options are available in various sizes, which affect their load-bearing capabilities. Think about the environment too; corrosive environments may require additional protection.

Next, review the grating's design features. Some grates have expanded metal designs, providing excellent grip and drainage. Others might be suited for pedestrian traffic only. Check the spacing between the bars as well. Too wide a gap can cause safety risks. It's essential to balance performance and safety, ensuring your choice meets specific needs.

Finally, consider installation aspects. Some grating types may require special tools or skills to install. Reflect on whether your team has the necessary experience. Installation can become a challenge if plans aren’t clear. A poorly installed grate can lead to problems over time. Think about maintenance needs, too. Grating should be easy to clean and durable against wear. Choose wisely, as the consequences of the wrong choice can be significant.

When selecting galvanized steel grating, load capacity is crucial. According to a report by the American Institute of Steel Construction, load capacities can significantly vary based on design and material specifications. For instance, a standard 1-inch thick galvanized steel grating can support up to 2,000 pounds when properly spaced. Understanding these specifications helps ensure safety and functionality.

Strength factors also play an essential role. The tensile strength of galvanized steel typically ranges between 35,000 to 50,000 psi. This means it can withstand heavy loads without permanent deformation. However, users often underestimate the importance of proper installation. An improperly installed grating can lead to structural failures, causing unsafe conditions.

Moreover, considering environmental factors is key. Galvanized steel performs well in corrosive environments, but exposure to extreme weather can affect its durability. Regular inspections are necessary to identify any signs of wear and tear. This proactive approach ensures the longevity of the grating and its effectiveness in load-bearing applications. It's a learning curve; even slight oversights can lead to significant consequences.

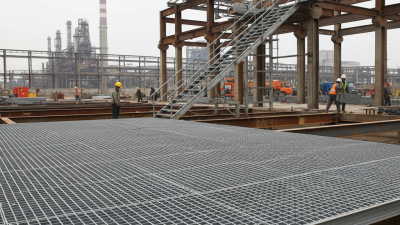

When installing galvanized steel grating, several factors need attention to ensure optimal performance. Begin by assessing the location where the grating will be placed. Will it be exposed to heavy loads or corrosive materials? These questions shape your choice. Proper installation is key. Ensure the grating is securely fastened to avoid shifting. Missing bolts or improper alignment can lead to safety hazards.

Maintenance is an ongoing task that should not be overlooked. Regular inspections help detect rust or wear. Rust can develop if the protective coating is chipped. Cleaning is equally important. Simple methods, like power washing or scrub brushes, can make a difference. Remember, neglecting these small details can lead to costly repairs later.

Adapting to the environment is also crucial. If the grating will be in a damp area, consider drainage solutions to reduce water accumulation. Sometimes, a quick fix won't suffice. Reflect on how decisions impact longevity and safety. Choose wisely to ensure your installation withstands the test of time.