When it comes to ensuring safety in various environments, the choice of flooring solutions is critical. One such solution, Anti Slip Bar Grating, has gained attention for its effectiveness in preventing slips and falls, which account for a significant portion of workplace injuries. According to the Occupational Safety and Health Administration (OSHA), slips, trips, and falls are among the leading causes of lost workdays, resulting in billions in costs annually. This highlights the importance of selecting appropriate safety equipment, including flooring materials that provide traction and stability.

Choosing the best Anti Slip Bar Grating involves understanding not only the material properties but also the specific application requirements. The National Floor Safety Institute (NFSI) underscores that the proper selection of slip-resistant surfaces can reduce the risk of accidents significantly. Factors such as load capacity, installation environment, and maintenance requirements should be carefully evaluated to ensure optimal performance. By considering these factors, organizations can enhance safety measures, reduce liability, and create a safer environment for workers and visitors alike.

In summary, as safety remains a top priority across various industries, the thoughtful selection of Anti Slip Bar Grating can make a substantial difference in mitigating hazards. As the statistics reflect, investing in high-quality, slip-resistant materials is not just a regulatory compliance measure but a proactive step toward fostering a culture of safety.

When selecting anti slip bar grating for safety purposes, several key factors should be taken into account. First, consider the environment where the grating will be installed. Wet, oily, or chemically hazardous areas demand grating with a higher slip resistance. Look for materials that not only provide toughness but also have surface textures specifically designed to enhance grip in challenging conditions.

Another important aspect to evaluate is the load capacity of the grating. Different applications may require different load ratings, so it’s crucial to assess the weight the grating must support and choose a product that meets those specifications. Additionally, consider the spacing between bars; narrower spacing can provide increased safety, especially in environments where small objects might fall through or when stability for foot traffic is necessary.

Tips: Always conduct a risk assessment of the area where the grating will be installed to identify specific safety needs. Consult with professionals or safety guidelines to ensure that your choice meets relevant safety standards. Moreover, do not overlook regular maintenance; keeping the grating clean and free from debris will help maintain its slip-resistant properties over time.

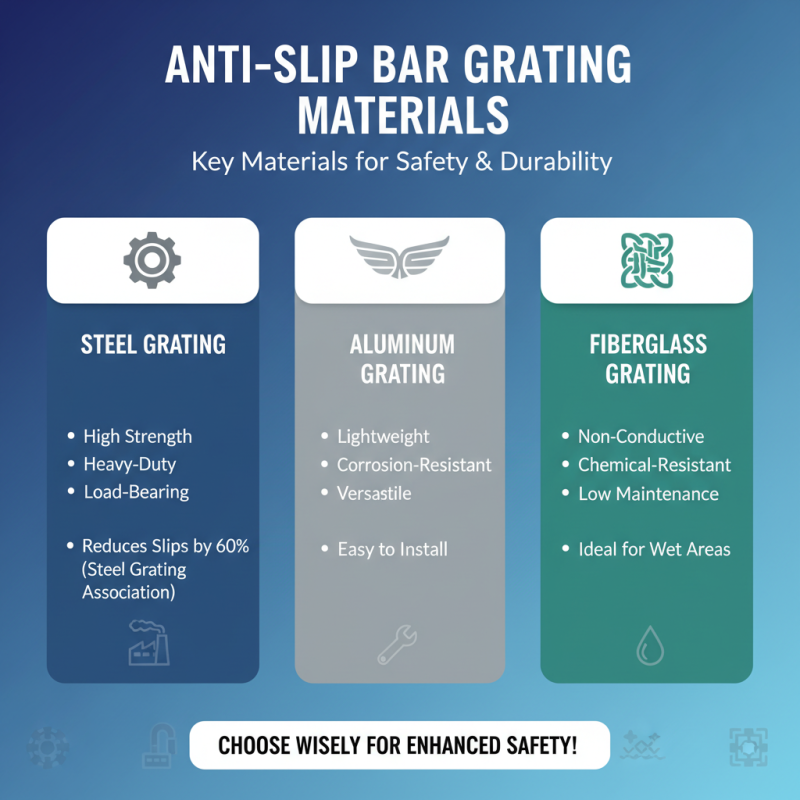

Choosing the right anti-slip bar grating is crucial for safety in various settings, such as industrial facilities, commercial spaces, and public areas. The materials used for anti-slip grating play a significant role in determining their effectiveness and durability. Common materials include steel, aluminum, and fiberglass, each offering unique advantages. Steel grating is known for its high strength and load-bearing capabilities, making it ideal for heavy-duty applications. According to a report by the Steel Grating Association, correctly installed steel grating can reduce slip incidents by up to 60%.

Aluminum grating combines lightweight properties with good corrosion resistance, making it suitable for outdoor environments. Its slip-resistant surfaces, often achieved through various textures and finishes, provide enhanced safety while being easier to handle and install. Meanwhile, fiberglass reinforced grating is chemically resistant and non-conductive, perfect for environments where safety from electrical hazards and corrosive substances is paramount. Studies show that fiberglass grating can lower slip incidents by up to 50% in wet conditions, highlighting its effectiveness.

Tips: When selecting anti-slip grating, consider the specific environment and the types of hazards present. Always evaluate the load requirements and choose a material that offers a balance between strength and slip resistance. Additionally, regularly inspecting and maintaining grating surfaces can significantly extend their longevity and safety performance.

When selecting anti-slip bar grating for safety applications, understanding load capacity and safety standards is paramount. Load capacity refers to the maximum weight that the grating can support without compromising its structural integrity. This is typically determined through rigorous testing and is essential for ensuring that the grating can bear the loads imposed by foot traffic, vehicles, or heavy machinery in various settings. It's crucial to assess both static and dynamic loads, as factors like movement and impact can influence how the grating performs under different conditions.

In addition to load capacity, adherence to safety standards plays a pivotal role in selecting the right anti-slip grating. Various regulations outline the parameters for slip resistance, load-bearing capabilities, and material durability. These standards are designed to protect users from accidents and injuries. When choosing grating, ensure that it meets the specific safety requirements relevant to your environment, whether it's industrial, commercial, or public spaces. Familiarizing yourself with these standards not only helps in making an informed choice but also minimizes the liability risks associated with safety failures. Proper evaluation of these factors will lead to a safer and more reliable installation.

| Type of Grating | Load Capacity (lbs) | Material | Slip Resistance Rating | Safety Standard Compliance |

|---|---|---|---|---|

| Steel Bar Grating | 3000 | Steel | High | ASTM R13 |

| Aluminum Grating | 2500 | Aluminum | Medium | ADA, OSHA |

| Fiberglass Grating | 1500 | Fiberglass | Very High | ISO 9001 |

| Plastic Grating | 1200 | Plastic | Medium | ANSI/ISEA 125 |

When choosing anti-slip bar grating for safety needs, surface texture and slip resistance ratings are critical factors to consider.

Surface texture refers to the physical characteristics of the grating that enhance grip. Textured surfaces can range from mild to aggressive patterns, impacting how effectively they prevent slips and falls.

It's essential to assess the environment where the grating will be installed; for instance, a *wet or oily area* may require a more textured surface for optimal slip resistance.

Slip resistance ratings are determined through standardized tests that measure how well a surface can prevent slips under various conditions. These ratings are typically based on the coefficient of friction, which indicates how much traction can be expected.

When selecting bar grating, look for products that provide clear slip resistance ratings, ensuring they meet industry standards for your specific safety requirements.

Tips: Before making a purchase, consider testing samples of different textures in your environment to see which works best.

Additionally, review safety regulations relevant to your industry, as they often provide guidance on slip resistance requirements. Always prioritize durability in your choice,

as a robust grating not only enhances safety but also withstands the test of time, reducing the need for frequent replacements.

When installing anti-slip bar grating, it is crucial to ensure that the surface is clean and dry. Begin by measuring the area where the grating will be placed to confirm the correct dimensions. It is recommended to use high-quality mounting hardware to secure the grating in place, as this will contribute to its effectiveness in preventing slips. Additionally, ensure that the grating is properly aligned and level to avoid any potential hazards. Regular inspections of the installation will help identify any signs of wear or displacement that may compromise safety.

Maintenance of anti-slip bar grating is equally important for ensuring long-term effectiveness. Routine cleaning should be performed to remove any debris, grease, or moisture that may accumulate on the surface. Depending on the environment, a non-abrasive cleaner may be used, followed by rinsing with water. It is also advisable to periodically check for any damages such as cracks or loose fittings and to address them promptly to maintain the integrity of the grating. By following these installation and maintenance tips, you can enhance the safety of your environment significantly.

This chart illustrates the importance of various safety factors when selecting anti slip bar grating. Each factor is rated on a scale from 1 to 10, highlighting the significance of slip resistance as the highest priority, followed closely by material durability and weight capacity.