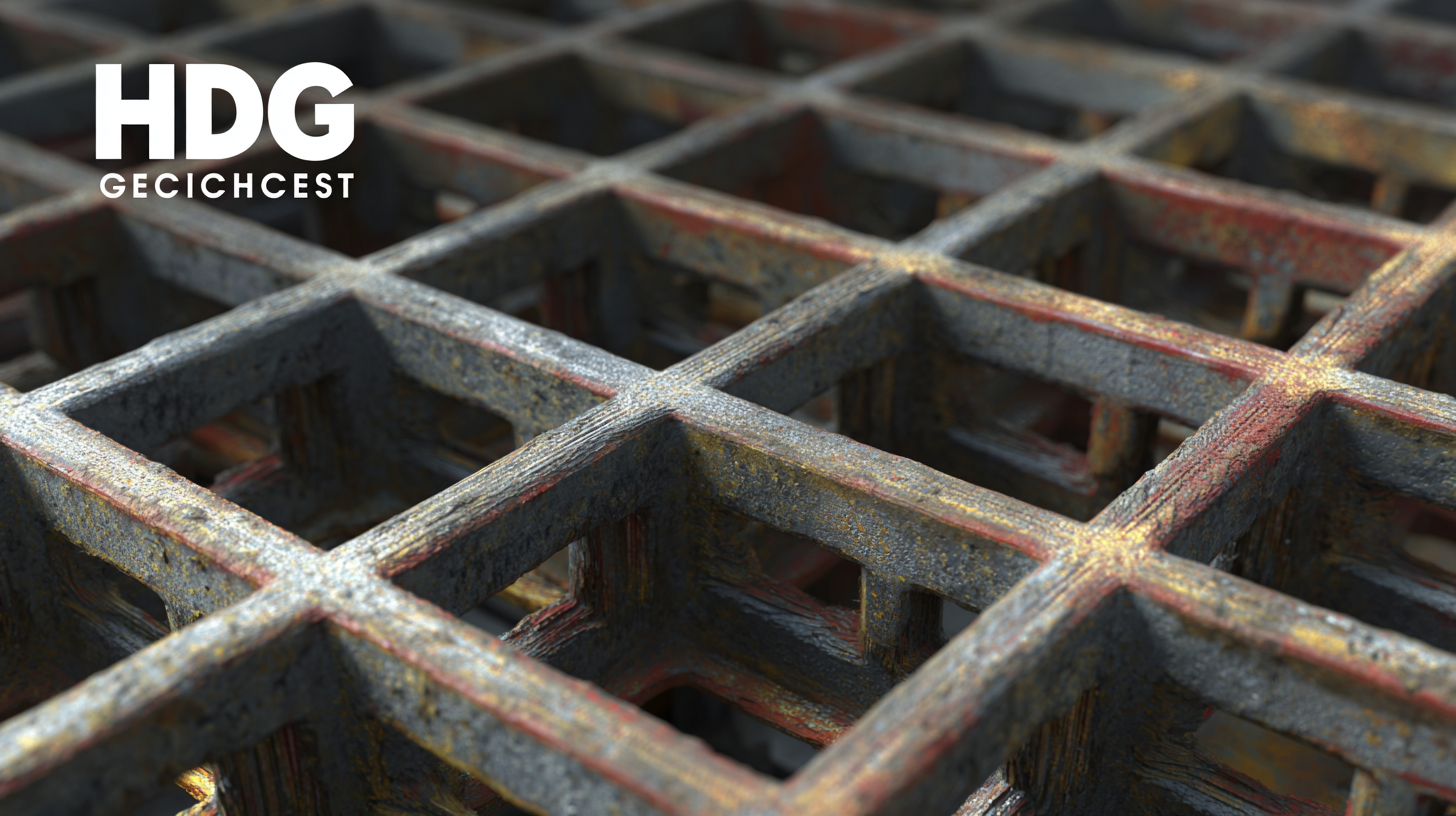

When it comes to enhancing safety and efficiency in industrial environments, sourcing the right materials is paramount. One such material that stands out in performance and durability is HDG grating, or hot-dipped galvanized grating. Known for its corrosion resistance and structural integrity, HDG grating serves as an ideal solution for various applications, from walkways and platforms to drainage covers and more. As industries seek to optimize their operations while ensuring a secure environment, understanding the benefits and key features of HDG grating becomes essential.

This ultimate checklist will guide you through the critical factors to consider when sourcing HDG grating, ensuring that your choices not only meet your industrial needs but also adhere to the highest standards of quality and safety.

When sourcing hot-dip galvanized (HDG) grating for industrial applications, understanding key factors is crucial for making informed decisions. One of the most significant considerations is the environmental impact of the products you choose. As industries worldwide increasingly focus on sustainability, integrating green procurement practices can enhance corporate social responsibility. With the global procurement as a service market expected to grow from $6.91 billion in 2024 to $14.52 billion by 2032, it's apparent that organizations are prioritizing sustainable and efficient sourcing options.

Moreover, the demand for HDG grating is also influenced by trends in construction and infrastructure development. With a compound annual growth rate (CAGR) of 9.9%, the industrial sector is actively seeking high-quality materials that meet safety and performance standards while minimizing lifecycle costs. In this context, HDG grating provides not only durable and corrosion-resistant solutions but also aligns with the broader trends towards environmental, social, and governance (ESG) initiatives. As procurement strategies evolve, understanding these dynamics can lead to better sourcing decisions that fulfill both operational needs and sustainability goals.

When sourcing HDG grating for your industrial projects, identifying reliable manufacturers is crucial for ensuring product quality and longevity. According to a recent industry report by the International Grating Association, nearly 42% of project delays are attributed to subpar materials that fail to meet safety standards. This highlights the importance of thorough quality assurance when selecting a supplier. Look for manufacturers that are certified in accordance with ISO 9001, which guarantees consistent quality management systems.

Tip: Always request material test reports, including load capacity and corrosion resistance data, to verify that the grating meets your project’s technical specifications. Furthermore, it’s beneficial to assess the manufacturer’s history: a company with over 10 years of experience usually indicates a reliable track record in delivering high-quality products.

Additionally, consider the manufacturer’s commitment to innovation and compliance with industry regulations. According to a survey by the National Association of Grating Manufacturers, 68% of buyers prefer suppliers who adopt new technologies and adhere to environmental standards.

Tip: Engage in direct communication with potential manufacturers, asking specific questions about their production methods and quality control measures. This not only demonstrates your thoroughness but also helps build a relationship based on transparency and trust.

When sourcing hot-dip galvanized (HDG) grating for industrial applications, it's essential to understand the various types available and their specific uses. HDG grating is typically categorized into several types: steel grating, fiberglass grating, and aluminum grating, each with unique properties suited for different environments. According to a report by Research and Markets, the global grating market is expected to grow at a CAGR of 5.2% through 2025, signaling a rising demand for these industrial materials across various sectors.

Steel grating is renowned for its strength and durability, making it a popular choice for heavy-load applications, including platforms and walkways in manufacturing and construction sites. In contrast, fiberglass grating offers excellent corrosion resistance and is ideal for chemical processing plants where exposure to harsh substances is a concern. Aluminum grating, while lighter and easier to handle, is often used in environments where weight savings are critical, such as in transportation or marine applications. Understanding these distinctions can significantly impact the performance and longevity of grating in your specific industrial use case.

| Type of HDG Grating | Material | Load Capacity | Applications | Standard Sizes |

|---|---|---|---|---|

| Close Mesh Grating | Steel | Heavy Duty | Platforms, Walkways | 2' x 6', 3' x 10' |

| I-Bar Grating | Aluminum | Moderate Duty | Trench Covers, Drainage | 4' x 8', 3' x 6' |

| Heavy Duty Grating | Steel with HDG | Very Heavy Duty | Heavy Machinery, Oil Rigs | 4' x 10', Custom Sizes |

| Spanning Grating | Fiberglass | Light to Moderate Duty | Chemical Plants, Decking | 2' x 4', 3' x 10' |

When sourcing HDG (Hot-Dip Galvanized) grating for industrial applications, understanding the essential certifications and standards that suppliers must adhere to is critical. Look for suppliers that comply with the American Society for Testing and Materials (ASTM) standards, which outline the minimum requirements for material selection and performance. A supplier certified under ASTM A123 ensures that the galvanization process meets rigorous quality checks, leading to enhanced corrosion resistance and longevity of the grating. This certification indicates that the grating can withstand harsh industrial environments, making it a reliable choice for various applications.

In addition to ASTM certification, ISO (International Organization for Standardization) certification is also vital. Suppliers with ISO 9001 certification demonstrate a commitment to quality management systems and consistent product delivery. This standard reassures buyers that the supplier implements systematic processes to monitor and improve quality. Furthermore, compliance with industry-specific standards, such as OSHA regulations for workplace safety, can indicate that the supplier prioritizes safe practices in production and handling. By ensuring that your HDG grating supplier meets these key certifications, you can significantly mitigate risks and enhance the integrity of your industrial projects.

When sourcing the best hot-dipped galvanized (HDG) grating for industrial applications, evaluating supplier pricing and delivery options is crucial for achieving optimal return on investment (ROI). A thorough analysis of pricing models is essential, as costs can vary significantly between suppliers. Look for transparency in pricing, including hidden fees, bulk order discounts, and potential for price negotiations. Understanding the full scope of costs associated with HDG grating—such as installation, maintenance, and lifecycle expenses—can illuminate the overall value offered by different suppliers.

Moreover, delivery options can have a substantial impact on operational efficiency. Suppliers that offer flexible shipping schedules and quick turnaround times can minimize downtime, allowing businesses to stay on track with production goals. It's advisable to assess each supplier's logistics capabilities, including their track record for on-time delivery and their ability to handle large orders. By balancing cost considerations with logistical efficiency, businesses can make informed decisions that enhance their overall project outcomes and maximize ROI.