Steel grating is widely used in various industries due to its strength, durability, and cost-effectiveness. Calculating steel grating weight efficiently is crucial for project planning. According to a report by the American Institute of Steel Construction (AISC), accurate weight determination helps in optimizing material usage and minimizing costs.

Understanding "Steel Grating Weight" involves several factors, including size, thickness, and type of material. A report from the National Steel Bridge Alliance indicates that errors in weight calculations can lead to budget overruns and project delays. Each grating type has unique properties that influence its overall weight.

In practice, professionals often overlook the importance of precise calculations, resulting in inefficiencies. A simple miscalculation can have ripple effects on an entire project. Effective strategies for calculating weight can significantly improve operational efficiency and resource allocation. The construction industry needs to address these issues to enhance productivity.

Steel grating is essential in various industries. It provides strength, stability, and safety. Understanding its materials and properties helps in selecting the right type for your needs. Typically, steel grating consists of carbon steel or stainless steel. Each material offers unique benefits.

The weight of steel grating depends on its dimensions and the thickness of steel used. It's crucial to know these parameters. For example, a thicker grating will be heavier. This impacts load capacity and installation methods. When calculating weight, consider both area and material density.

Struggling with accuracy is common during calculations. Slight errors can lead to significant weight differences. Always double-check your calculations. Additionally, keep in mind environmental factors that could influence durability. Over time, exposure to moisture can corrode steel, affecting its weight and strength. Make sure to think about these aspects when selecting steel grating.

Calculating the weight of steel grating involves several key factors. The type of steel used significantly impacts weight. Different grades offer varied densities, which can change the final weight estimation. For instance, stainless steel is generally heavier than mild steel. Understanding the specific application helps in choosing the right material, influencing both durability and weight.

Grid spacing and thickness also play crucial roles. A denser grid means more steel, increasing overall weight. Conversely, wider spacing can reduce weight but may sacrifice strength. The thickness of the bars further adjusts weight calculations, requiring careful consideration based on load-bearing needs. These details might seem minor but can lead to substantial weight differences.

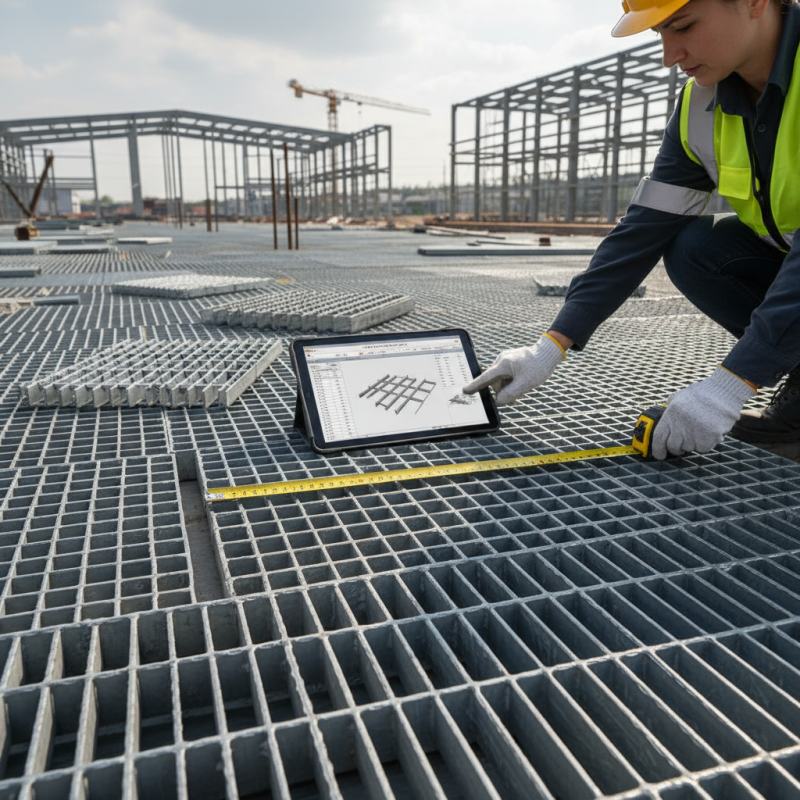

Manufacturers sometimes overlook the importance of accurate measurements, leading to errors. Precision tools must be used to determine dimensions correctly. Even small discrepancies can affect the total weight significantly. Regular reviews of calculations are essential for maintaining accuracy. Embracing a thorough approach ensures reliable weight estimations for diverse applications.

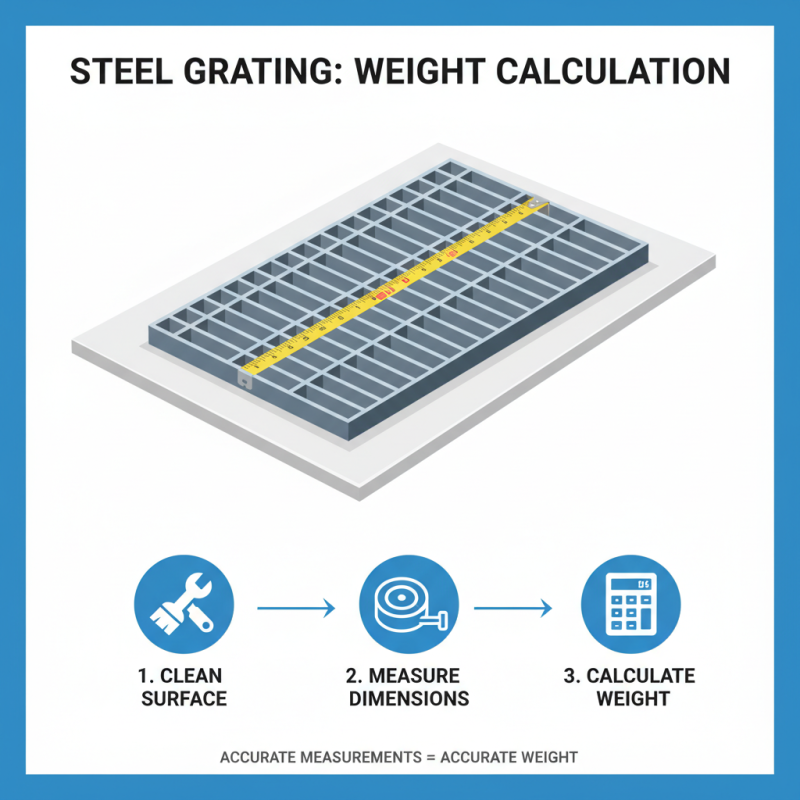

Measuring steel grating dimensions is crucial for accurate weight calculations. Start by laying the grating on a flat surface. Ensure it is clean and free from debris. This step helps in getting precise measurements.

Using a tape measure, find the length and width. Note these dimensions carefully. For most grates, the width can range from a few inches to several feet. Understanding these dimensions helps in calculating the area.

Next, measure the thickness. It is often overlooked, but thickness significantly affects weight. A thicker grating usually means more material. Write down all measurements. Small errors can lead to serious discrepancies later. Check and double-check your notes. If they seem off, re-measure to ensure accuracy. The details matter.

Calculating the weight of steel gratings is essential for various projects. The process can be simplified using specific formulas. The weight is typically calculated using the formula: Weight = Volume x Density. The density of steel averages around 490 pounds per cubic foot (or 7,850 kg/m³). For example, a 1-inch thick steel grating that measures 3 feet by 2 feet will have a volume of 6 cubic feet. Multiplying this by the density gives a total weight of approximately 2,940 pounds.

When calculating, you must consider the dimensions of the grating. Each section's length, width, and thickness are crucial for an accurate estimate. Measuring errors can lead to incorrect weight calculations, impacting your project. Always double-check your figures before proceeding.

Tips:

Measuring the weight of steel grating accurately can be challenging. Correct calculations are crucial for various applications. It can be helpful to have a thorough understanding of the grating's specifications. The weight depends on several factors, such as thickness, material type, and dimensions. Collecting this data beforehand ensures accuracy.

Using precise tools is essential. A digital scale can provide reliable weights. However, manually calculating the weight requires diligence. The formula involves multiplying the volume by the density of the steel. Sometimes, mistakes occur during this process. Double-checking dimensions reduces errors significantly. It's also important to consider any coatings or treatments that may alter weight.

Accuracy can still be elusive. Environmental factors like moisture can affect measurements. Ensuring the grating is clean and dry is vital. Small details can greatly impact the final calculation. Making a checklist before measurements can streamline the process. The aim should be to minimize uncertainties and enhance reliability in measurements.