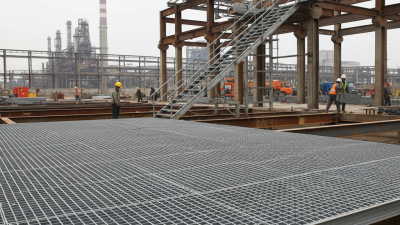

Serrated Steel Grating has emerged as a critical component in industrial and commercial safety and durability applications. With its unique design that enhances traction and slip resistance, this type of grating plays a vital role in various environments, such as manufacturing facilities, walkways, and platforms. According to a recent report by the Global Grating Market Analysis, the demand for serrated steel grating is expected to grow at a CAGR of 4.2% from 2023 to 2028, driven by the increasing focus on workplace safety standards and regulatory compliance.

Industry expert Dr. Emily Thompson, a leading figure in structural safety research, emphasizes the importance of serrated steel grating in preventing workplace accidents, stating, "The implementation of serrated steel grating not only enhances foot traction but also significantly reduces the potential for slips and falls in hazardous environments." As more industries prioritize the implementation of robust safety measures, the selection of the right serrated steel grating becomes paramount to ensure both safety and durability. This article will explore the best options available in the market, aiming to guide stakeholders in making informed decisions while considering factors such as material quality, load-bearing capacity, and corrosion resistance.

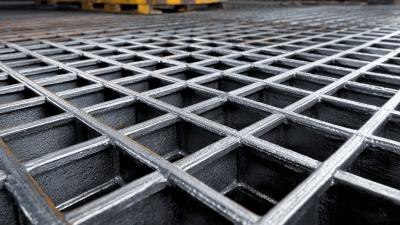

Serrated steel grating is renowned for its unique design that enhances safety and durability in a range of industrial applications. One of the key features of this type of grating is its serrated surface, which provides superior slip resistance. This is particularly beneficial in environments where moisture or debris can create hazardous walking conditions. The serrated edges create friction underfoot, significantly reducing the risk of slips and falls, thus making it an ideal choice for walkways, platforms, and other high-traffic areas.

In addition to its safety advantages, serrated steel grating offers exceptional durability. Made from high-quality steel, it is resistant to wear and tear, which makes it suitable for heavy-duty use. This form of grating can withstand extreme conditions, including harsh weather and heavy loads, ensuring longevity and reliability in various settings. Moreover, its low maintenance requirements further enhance its appeal, as it typically needs only regular cleaning to maintain its performance and appearance.

Tips: When selecting serrated steel grating for a project, consider the specific application and load requirements to ensure optimal performance. Additionally, verify the product's compliance with safety standards in your industry. Regular inspections and maintenance can also help extend the life of the grating, ensuring it continues to provide maximum safety and durability over time.

When it comes to selecting serrated steel grating, several types are available to meet diverse safety and durability requirements. One of the most common options is the Standard Serrated Grating, which features a series of serrated surfaces that enhance slip resistance. This type of grating is ideal for walkways and platforms in industrial settings, providing a secure footing even in wet or oily conditions. The serrated edges effectively channel liquids away, minimizing the risk of slipping and accidents.

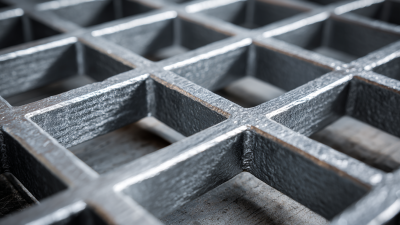

Another popular option is the Heavy-Duty Serrated Grating, which is designed for areas subject to heavy traffic or extreme conditions. This type of grating possesses thicker and more robust materials, ensuring it can withstand significant loads while maintaining structural integrity. Heavy-duty grating is commonly utilized in warehouses, factories, and other high-load environments, delivering both safety and longevity. Furthermore, there are specialized serrated gratings available, such as those with corrosion-resistant coatings, perfect for environments exposed to chemicals or harsh weather conditions. Each type presents unique advantages, making it essential to choose the right one based on specific application needs.

| Type of Serrated Steel Grating | Surface Type | Load Capacity (lbs) | Applications | Maintenance Level |

|---|---|---|---|---|

| Heavy Duty Serrated Grating | Serrated | 5000 | Industrial Flooring | Low |

| Light Duty Serrated Grating | Serrated | 2000 | Walkways | Moderate |

| Standard Serrated Grating | Serrated | 3000 | Platforms | Low |

| Safety Grating with Anti-Slip | Serrated + Anti-slip | 3500 | Stairways | Moderate |

| ADA Compliant Serrated Grating | Serrated | 2500 | Public Access Areas | Low |

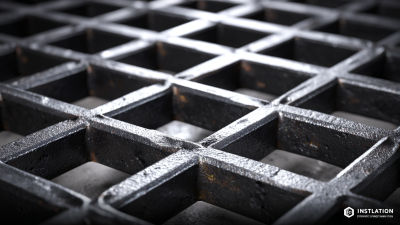

When it comes to selecting serrated steel grating for enhanced safety and durability, evaluating the materials and coatings used is crucial. High-quality steel grades, such as ASTM A36 and A992, are preferred for their strength and longevity. Reports indicate that grating constructed from these materials can withstand heavy loads, making them ideal for industrial and commercial applications. To further increase durability, many manufacturers recommend galvanized coatings that provide excellent corrosion resistance, thereby extending the lifespan of the grating significantly.

Tips for maintaining steel grating include regular inspections to identify any signs of wear or corrosion early. Additionally, applying anti-slip coatings can enhance safety for foot traffic in bustling environments. The use of non-corrosive materials around grating, as mentioned in various industry studies, can reduce the risk of degradation, ensuring that the grating maintains its structural integrity over time.

Ultimately, investing in the right materials and protective coatings is essential for achieving maximum safety and durability in serrated steel grating. Research suggests that properly maintained grating can last anywhere from 15 to 25 years, highlighting the importance of diligent care and appropriate selection based on the specific application environment.

When selecting serrated steel grating for various applications, adhering to safety compliance standards and regulations is paramount. These standards, which vary by region and industry, are designed to ensure that steel grating systems provide not only structural integrity but also safe environments for both workers and the general public. In the United States, for example, the American National Standards Institute (ANSI) outlines specifications that grating manufacturers must follow to ensure slip resistance and load capacity. Compliance with these standards minimizes the risk of accidents and injuries, thereby enhancing workplace safety.

In addition to ANSI standards, many organizations must also reference guidelines from the Occupational Safety and Health Administration (OSHA). OSHA emphasizes the importance of selecting the appropriate type of grating based on the potential hazards present in a facility—such as heavy machinery or pedestrian traffic. Moreover, proper installation and maintenance play critical roles in ensuring that steel grating continues to perform effectively over time. Regular inspections and adherence to manufacturer recommendations help maintain compliance with safety regulations, ultimately contributing to a safer working environment that prioritizes durability and dependability.

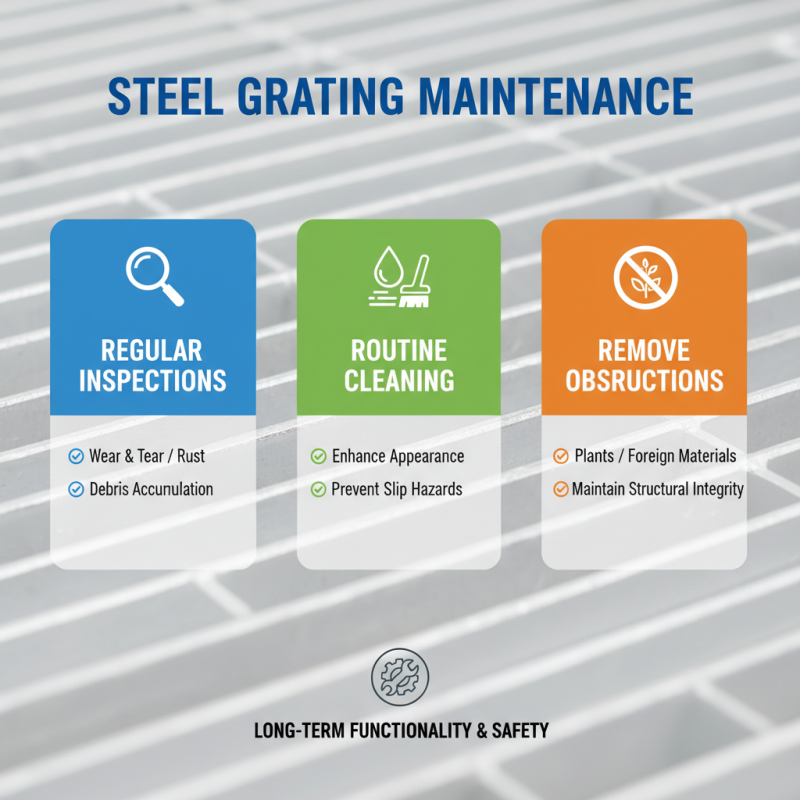

Maintaining steel grating is crucial for ensuring its long-term functionality and safety. Regular inspections should be conducted to identify any wear and tear, rust, or debris accumulation. Cleaning the grating regularly not only enhances its appearance but also prevents slip hazards. Make sure to remove any plants or foreign materials that could compromise structural integrity.

Another key tip is to apply protective coatings. Using high-quality sealants or paints can help guard against oxidation and environmental wear. These coatings not only prolong the life of the grating but also reduce maintenance efforts in the future. Additionally, ensure that the grating is installed correctly, as improper installation can lead to quicker degradation and unsafe conditions.

It's also wise to consider load capacity during maintenance checks. Heavy loads can strain the steel grating, leading to potential damage. Regularly verify that the grating continues to meet safety standards and is suitable for the intended application. By following these maintenance tips, you can enhance the durability of your steel grating significantly.