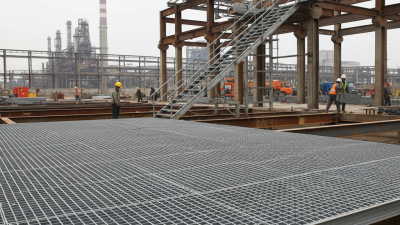

When it comes to construction projects, choosing the right materials is crucial for durability and functionality. Among the options available, Galvanized Steel Bar Grating stands out as an ideal solution for a variety of applications, including walkways, platforms, and industrial flooring. This versatile material offers numerous advantages, such as resistance to corrosion and wear, making it an excellent choice for environments that are subjected to heavy loads and harsh conditions.

In this article, we will explore the top ten options for Galvanized Steel Bar Grating, highlighting their unique features and benefits. From industrial facilities to commercial spaces, the effectiveness and reliability of these gratings can significantly enhance safety and productivity. Whether you are designing a new construction or renovating an existing structure, understanding the best choices in galvanized steel bar grating can help you make informed decisions that lead to successful outcomes. Join us as we delve into the various types of galvanized steel bar grating that can meet your specific construction needs.

Galvanized steel bar grating is a crucial component in various construction projects, offering strength, durability, and versatility. The most common types include welded, riveted, and swage-locked grating. Welded grating is created by welding the bearing bars to the cross bars, resulting in a sturdy and robust structure ideal for heavy loads and harsh environments. This type is widely used in industrial applications where safety and longevity are paramount.

Riveted grating, on the other hand, is assembled using rivets, providing excellent resistance against impact and deformation. It is suitable for medium to heavy loads and is often found in applications such as walkway surfaces and platforms. Lastly, swage-locked grating features a unique locking mechanism that offers a seamless appearance and ease of installation. This type is particularly effective for applications requiring high open space for drainage while maintaining substantial load-bearing capacity. Each type of galvanized steel bar grating serves specific needs, making it essential to choose the right option based on the requirements of the construction project.

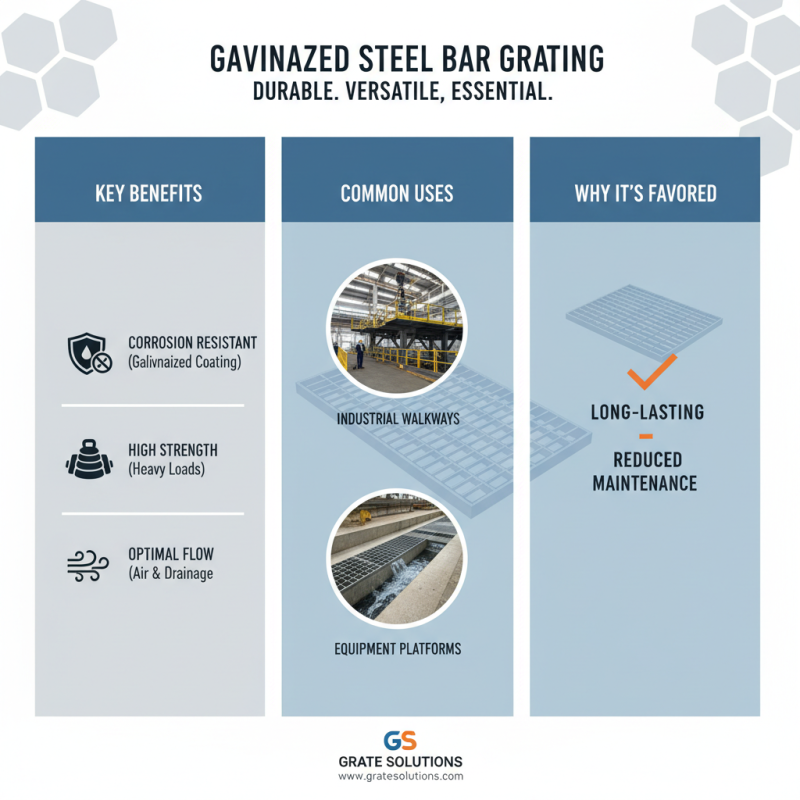

Galvanized steel bar grating is a preferred choice in construction due to its robust characteristics and wide range of applications. One of the key features is its exceptional durability, which stems from the galvanization process that involves coating steel with zinc to prevent rust and corrosion. This process typically extends the lifespan of the grating significantly, making it a reliable option for both indoor and outdoor environments. According to the American Galvanizers Association, galvanized steel can withstand corrosion for over 50 years, depending on the environmental conditions, which makes it ideal for industrial settings and harsh weather applications.

Another major benefit is the grating's load-bearing capacity, which is essential in high-traffic areas. Galvanized steel grating can handle substantial loads, with some designs rated for over 1,000 pounds per square foot. This capability is crucial not just for safety but also for reducing maintenance costs associated with frequent replacements or repairs. Furthermore, the open design of bar grating allows for efficient drainage and airflow, which can help mitigate issues related to water accumulation and debris buildup. The combination of strength, durability, and maintainability makes galvanized steel bar grating an indispensable asset for various construction projects, delivering both performance and peace of mind.

When selecting galvanized steel bar grating for construction projects, it's essential to consider several key factors to ensure the material meets your needs. First and foremost, assess the load-bearing capacity required for your specific application. Different projects demand varying levels of strength and durability, so understanding the weight that the grating will support is crucial. Additionally, consider the spacing between the bars; closely spaced bars provide better support for smaller objects, while wider spacing may be more suitable for other applications.

Another critical factor is the environment where the grating will be installed. Galvanized steel is known for its rust resistance, but the exposure to certain chemicals, humidity levels, or extreme weather conditions can influence the longevity of the material. Therefore, it's important to evaluate the environmental conditions and choose a grating that offers the best protection against potential corrosion. Finally, think about installation and maintenance requirements. Some grating options may be easier to install and maintain than others, impacting the overall efficiency and cost-effectiveness of the project. By considering these factors, you can make an informed decision that will enhance the safety and functionality of your construction.

| Option | Load Capacity (lbs) | Weight per Square Foot (lbs) | Thickness (inches) | Bar Spacing (inches) | Surface Finish |

|---|---|---|---|---|---|

| Vertical Bar Grate | 2000 | 3.0 | 1.0 | 1.5 | Hot-Dip Galvanized |

| Heavy Duty Grating | 3000 | 4.5 | 1.5 | 2.0 | Electro-Galvanized |

| Light Duty Grating | 1000 | 2.0 | 0.75 | 1.0 | Hot-Dip Galvanized |

| Flat Bar Grating | 2500 | 3.5 | 1.25 | 1.5 | Powder Coated |

| Architectural Grating | 1500 | 2.5 | 1.0 | 1.0 | Hot-Dip Galvanized |

Galvanized steel bar grating has emerged as a preferred solution for various construction applications due to its strength, durability, and resistance to corrosion. According to the American Galvanizers Association, galvanized coatings provide excellent protection against rust and abrasion, increasing the lifespan of steel structures significantly. In industrial environments, where exposure to moisture and chemicals is common, galvanized steel grating can last up to 30 years with minimal maintenance, making it a cost-effective choice for project managers and engineers.

In addition to its longevity, the versatility of galvanized steel bar grating caters to diverse construction needs. It can be utilized in walkways, platforms, and drainage covers, among other applications. A report published by Research and Markets indicates that the global market for metal grating is projected to grow at a CAGR of 5.1% from 2021 to 2028, driven by increased demand in the construction and infrastructure sectors. Moreover, with the implementation of safety regulations and standards, galvanized steel grating has gained traction as a go-to material for ensuring workplace safety while still being lightweight and easy to install. These factors highlight the importance of selecting the right type of grating for specific construction needs, ensuring that projects are completed effectively without compromising on safety or quality.

Galvanized steel bar grating has become a favored choice in various construction applications due to its durability and versatility. It is widely used in industrial settings, such as factories and warehouses, where heavy loads and foot traffic are common. The open design of the grating allows for efficient drainage and air circulation, making it ideal for walkways, platforms, and drainage covers. This feature is particularly beneficial in environments where moisture can lead to rust and deterioration, as the galvanized coating provides an extra layer of protection against corrosion.

In addition to industrial applications, galvanized steel bar grating is also utilized in commercial buildings, transportation facilities, and public areas. It is often employed in stairways and platforms within transit stations, where safety and accessibility are paramount. The slip-resistant surface of the grating enhances safety for pedestrians and workers alike, while its strength supports substantial weight loads. Furthermore, the aesthetic appeal and adaptability of the grating make it suitable for architectural elements, such as railings and facades, adding both function and style to construction projects.