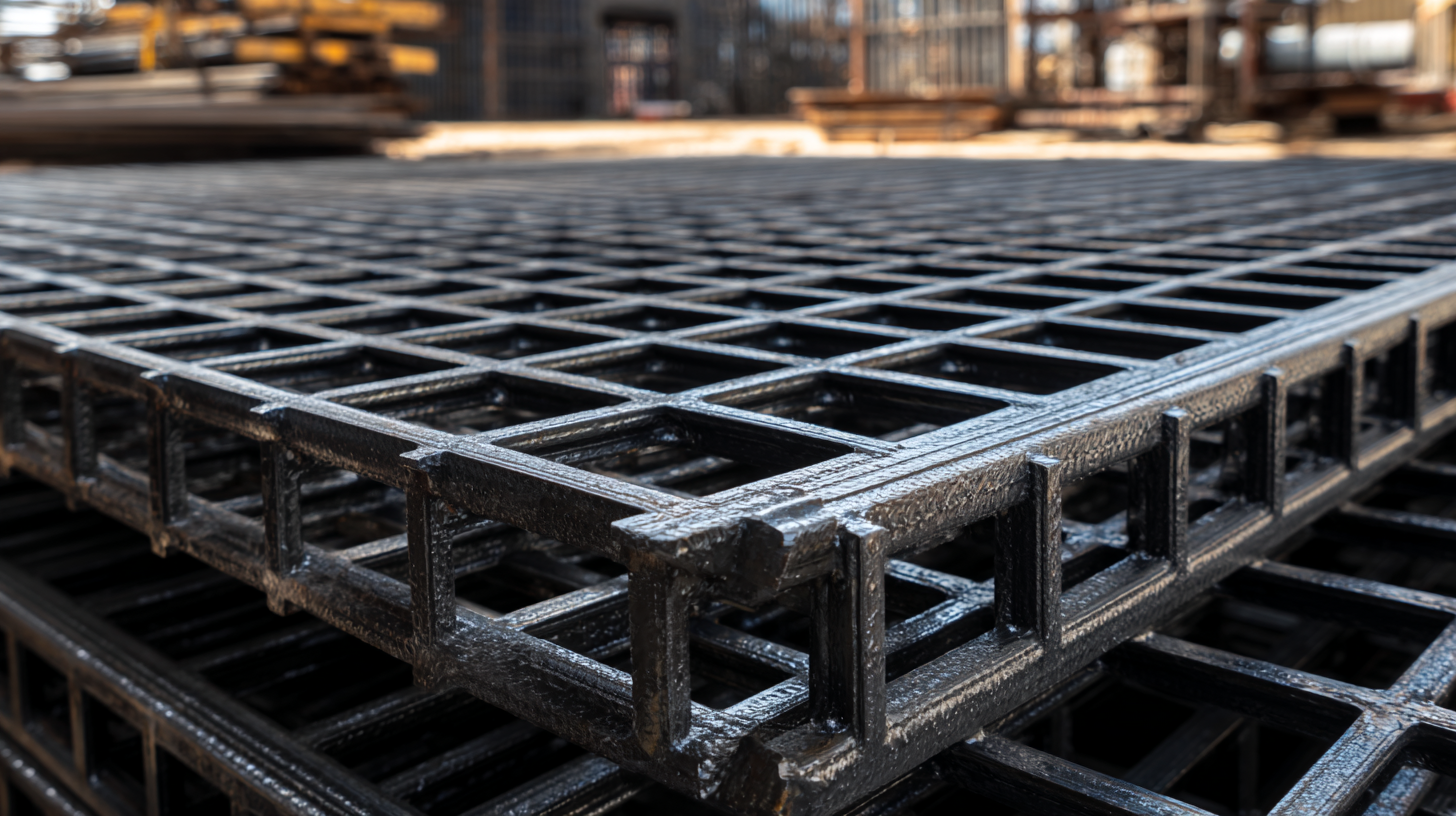

As industries continue to evolve towards more efficient and durable materials, black steel grating remains a critical component in various construction and manufacturing sectors. Understanding the implications of "Black Steel Grating Weight" plays a vital role in project planning and execution. According to a recent report by MarketsandMarkets, the global market for steel grating is projected to reach USD 8.6 billion by 2025, with heavy demand driven by the oil and gas, wastewater treatment, and construction industries. The weight of black steel grating is not just a matter of engineering; it directly influences load-bearing capacities, installation costs, and overall project efficiency. This blog will explore the seven best weight solutions for black steel grating that cater to global buyers, ensuring optimal performance without compromising on strength or safety.

As the demand for black steel grating continues to rise globally, emerging technologies are set to revolutionize production processes by 2025. Innovations in automation and robotics stand at the forefront, enhancing both efficiency and precision in manufacturing. Through the implementation of advanced welding techniques and automated cutting systems, manufacturers can achieve consistent quality, reducing waste while improving safety. These technologies not only streamline operations but also shorten lead times, allowing businesses to respond quickly to market demands.

Additionally, integrating smart technologies and data analytics into production lines offers unprecedented insights into operational performance. By leveraging real-time data, companies can optimize resource allocation and predict maintenance needs, reducing downtime and operational costs. The adoption of eco-friendly practices and materials in the production of black steel grating aligns with global sustainability goals, ensuring that the industry remains competitive while contributing positively to environmental efforts. This combination of technology and sustainability is expected to shape the future landscape of black steel grating production, making it more efficient and environmentally responsible by 2025.

| Solution | Weight (kg/m²) | Load Capacity (kN/m²) | Thickness (mm) | Application |

|---|---|---|---|---|

| Standard Grating | 60 | 5.0 | 25 | Industrial Flooring |

| Heavy Duty Grating | 80 | 8.0 | 30 | Oil & Gas Platforms |

| Lightweight Grating | 45 | 3.0 | 20 | Walkways |

| Custom Grating | 70 | 6.5 | 28 | Specialized Applications |

| Corrosion Resistant Grating | 65 | 7.0 | 26 | Chemical Facilities |

| Architectural Grating | 50 | 4.0 | 22 | Aesthetic Design |

| Safety Grating | 55 | 5.5 | 24 | High Traffic Areas |

When it comes to optimizing black steel grating for diverse applications, material innovation plays a pivotal role in enhancing weight efficiency. The modern industry increasingly relies on advanced steel treatments and composites that not only reduce overall weight but also maintain structural integrity and durability. High-strength steel alloys, for instance, have emerged as a popular choice due to their excellent tensile strength-to-weight ratio, allowing for thinner profiles that still bear substantial loads.

In addition to alloy innovations, surface treatments such as galvanization and powder coating significantly contribute to weight efficiency by improving corrosion resistance without adding unnecessary weight. These methods ensure that grating remains lightweight yet resilient against environmental wear and tear, extending its lifecycle. Furthermore, the integration of lightweight fillers and innovative manufacturing techniques, such as 3D printing, is reshaping the future of black steel grating, enabling designers to push boundaries while adhering to rigorous weight specifications.

As a result, global buyers can access solutions that not only meet structural requirements but also drive efficiency and cost-effectiveness in their projects.

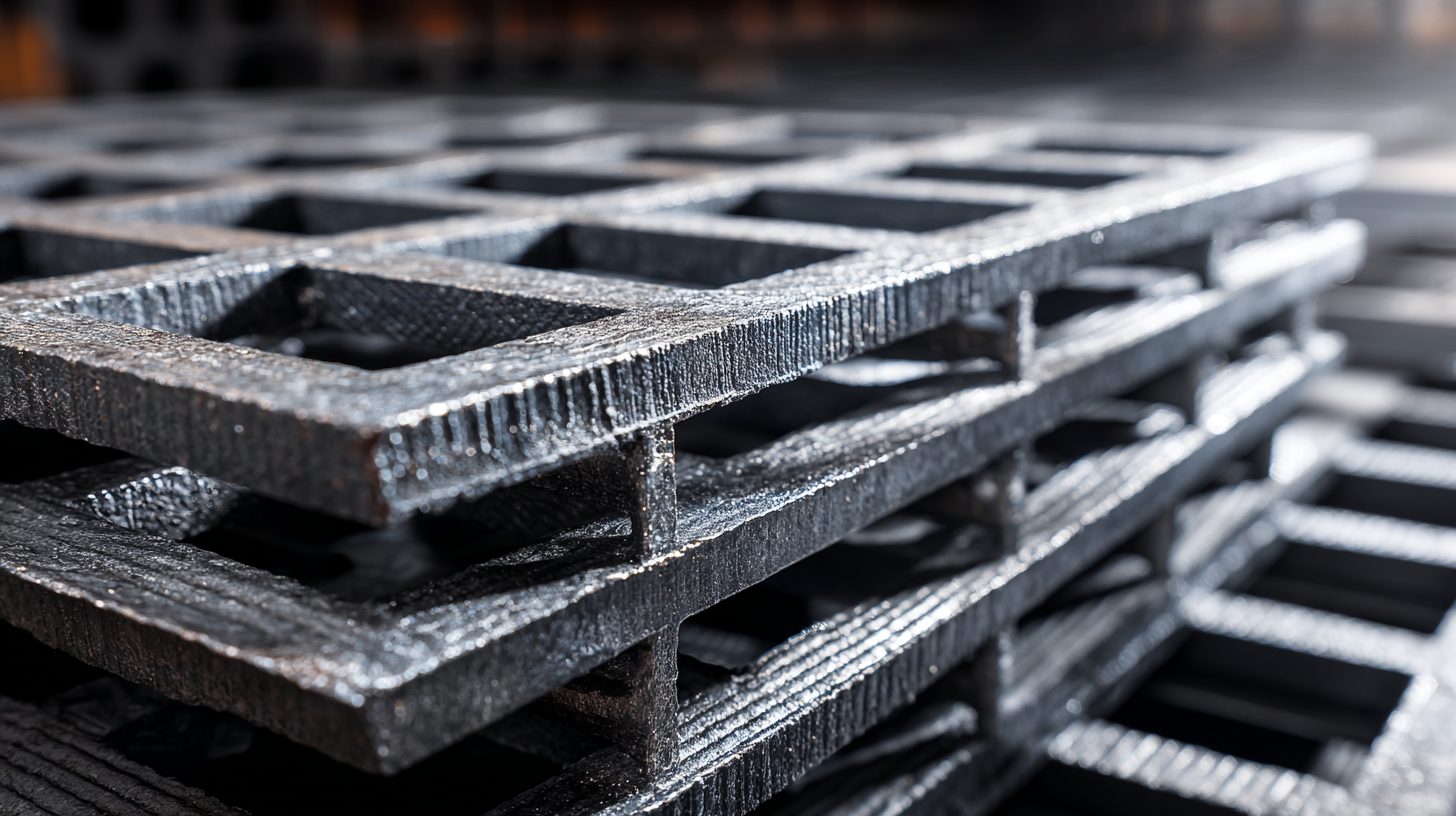

Sustainable practices in black steel grating manufacturing are becoming increasingly essential as global buyers seek environmentally conscious solutions. One significant trend is the use of recycled materials in the production of black steel grates. By sourcing high-quality recycled steel, manufacturers not only reduce the demand for new raw materials but also minimize energy consumption and greenhouse gas emissions associated with traditional steel production. This shift not only benefits the environment but also provides savings that can be passed on to buyers, making sustainable products more accessible.

Additionally, many manufacturers are implementing energy-efficient processes and technologies to streamline production. Techniques such as powder coating and protective coatings help enhance the durability of black steel gratings, prolonging their lifespan and reducing the need for replacements. This approach not only conserves resources but also supports a circular economy by ensuring that products can be reused or recycled at the end of their lifecycle. By prioritizing sustainability in manufacturing, suppliers can better meet the expectations of environmentally conscious global buyers while contributing to a more sustainable future.

The demand for black steel grating is projected to witness significant changes due to evolving market trends. According to a recent industry report by Market Insights, the global market for steel grating is expected to grow at a CAGR of 5.6% between 2023 and 2030. This growth is driven by increased construction activities, particularly in emerging economies, where infrastructure development is a priority. The rising focus on safety and durability in industrial facilities will also bolster the demand for black steel grating, known for its robustness and resistance to harsh environments.

Tips for buyers: When considering black steel grating solutions, always look for products that meet ASTM standards to ensure quality and compliance. Additionally, assessing the specific application requirements—such as load-bearing capacity and environmental factors—can help you select the most suitable grating type for your needs.

Furthermore, sustainability trends are playing a crucial role in shaping the future of black steel grating demand. The construction sector is increasingly adopting eco-friendly practices, leading to a rise in recycled steel usage. Reports indicate that nearly 60% of steel is now sourced from recycled materials, which not only reduces environmental impact but also offers cost savings.

Tips for buyers: It's beneficial to inquire about the sourcing practices of your suppliers, as those committed to sustainability may provide a competitive edge in both quality and pricing.

In the realm of manufacturing, effective weight management for black steel grating is crucial for optimizing operational efficiency and reducing costs. According to a recent report by the Global Steel Grating Market Analysis, companies can experience a significant decrease in transportation costs—up to 15%—by implementing smart solutions that streamline weight monitoring and management. Smart technologies, like IoT-based sensors, can provide real-time data analytics, enabling manufacturers to make informed decisions that enhance product quality while maintaining compliance with industry standards.

Another key factor in optimizing black steel grating weight management is the integration of advanced manufacturing techniques. Techniques such as Lean Manufacturing and Six Sigma have shown to improve process efficiency by as much as 30%, as outlined in the 2022 Industry Efficiency Report. By adopting these methodologies, manufacturers not only achieve precise weight specifications but also minimize material waste and reduce the carbon footprint of production. As global buyers increasingly prioritize sustainability, investing in these smart manufacturing solutions is vital for improving competitiveness and meeting the evolving demands of the marketplace.