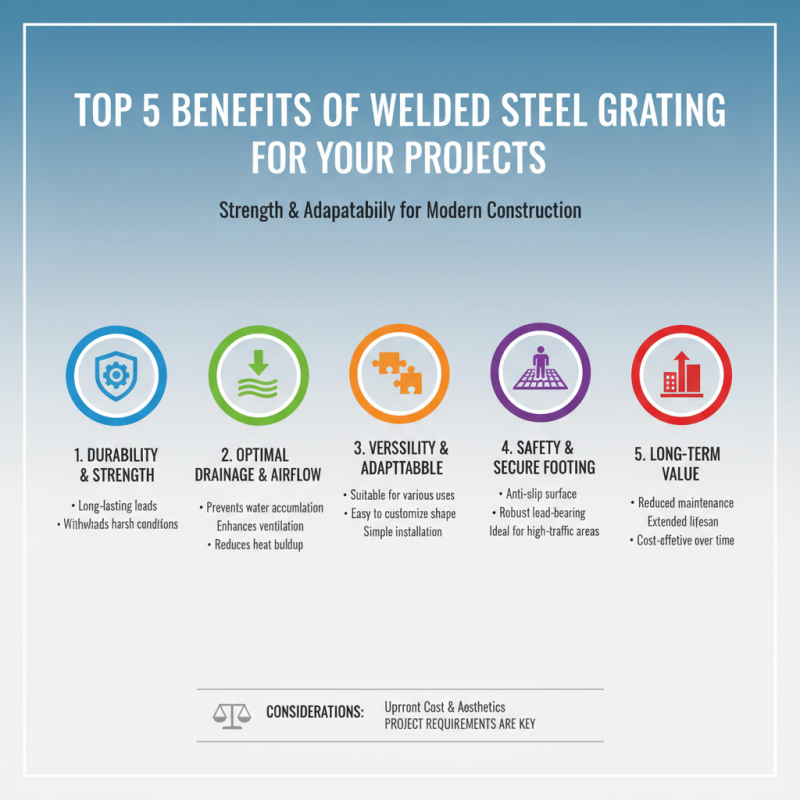

Welded Steel Grating has revolutionized the construction industry. Industry expert John Smith once stated, “Welded Steel Grating provides durability and adaptability for diverse projects.” This material is gaining attention for its strength and versatility.

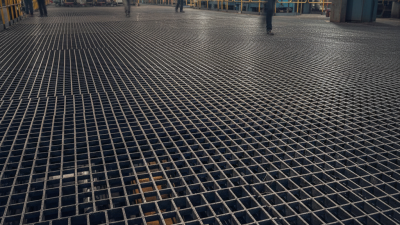

Engineers and architects are increasingly recognizing the numerous benefits of Welded Steel Grating. It is often used in flooring, walkways, and platforms. The grating allows for excellent drainage and airflow, which is particularly beneficial in industrial settings. However, not every project may find it suitable. Some might argue that alternatives can offer similar benefits at a lower upfront cost.

Despite this, the unique features of Welded Steel Grating cannot be overlooked. It delivers robust load-bearing capabilities. This can be critical for safety in high-traffic areas. While there are instances where it may not fit every aesthetic need, the functional advantages often outweigh these concerns. The right choice relies on project requirements.

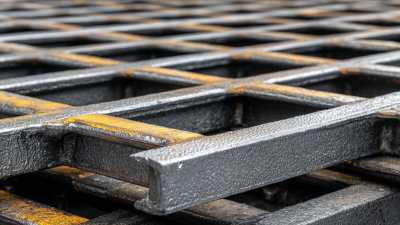

Welded steel grating offers significant advantages in structural support applications. Its robust design provides essential strength and stability for various projects. This material is highly durable, resistant to corrosion, and can withstand heavy loads. Projects in various industries benefit from its reliability. It enhances safety by providing a secure surface for foot traffic.

When choosing welded steel grating, consider the spacing of the bars. Too wide of a gap can lead to reduced support and potential hazards. Evaluate the environment, as exposure to chemicals may impact durability. A suitable coating can enhance resistance.

Tips: Always verify the load capacity of your chosen grating. Materials can sometimes have hidden vulnerabilities. Regular inspections of installed grating can prevent unforeseen failures. Ensure that your project meets safety standards through careful planning.

| Benefit | Description |

|---|---|

| High Strength | Welded steel grating provides superior strength and load-bearing capacity, making it ideal for heavy-duty applications. |

| Durability | Resistant to wear and corrosion, ensuring a long lifespan even in harsh environments. |

| Cost-Effective | Lower long-term maintenance costs due to its durability and resistance to environmental factors. |

| Versatile Applications | Suitable for a wide range of applications including flooring, walkways, and safety barriers. |

| Easy Installation | Designed for quick and easy installation, reducing labor time and overall project costs. |

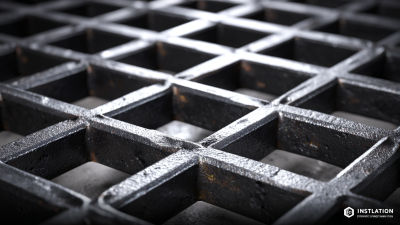

Welded steel grating is becoming increasingly vital in construction projects due to its enhanced safety standards. According to recent industry reports, welded steel grating can support load-bearing capacities up to 40,000 pounds per square foot, making it ideal for heavy machinery and foot traffic. This durable material resists environmental wear, reducing the risk of accidents caused by corrosion or structural failure.

Safety is the top priority. A study by the Occupational Safety and Health Administration (OSHA) highlighted that slip and fall accidents are a leading cause of workplace injuries. Welded steel grating's slip-resistant surface helps minimize these incidents, offering a secure footing even in wet conditions. In many industries, it is crucial to regularly assess the condition and safety features of any flooring system, including steel grating.

Tip: Regularly inspect your steel grating for signs of wear. Cracks or deformation can compromise safety. Also, consider the load requirements specific to your project—too much weight on a poorly supported grating can lead to failure. Utilizing proper installation techniques is essential to maximizing its benefits.

This chart illustrates the top benefits of using welded steel grating in construction projects, highlighting enhanced safety standards and load-bearing capacities.

Welded steel grating offers significant cost savings for various projects. Its durability and longevity reduce the need for frequent replacements. When investing in materials, this is crucial. Over time, the lower maintenance costs contribute to a more favorable budget outlook. Steel grating can withstand heavy loads, making it ideal for industrial environments.

Additionally, this type of grating is resistant to corrosion, which enhances its lifespan. In coastal regions, where saltwater exposure is common, this resistance becomes invaluable. While initial costs may seem high, the return on investment is impressive. Consider how often you will replace inferior materials.

However, it’s important to reflect on installation challenges. The labor costs might increase, especially for intricate designs. Understanding the long-term benefits can help outweigh these upfront expenses. Each project is unique, and careful planning is essential. Evaluating the specific needs of your project can lead to an effective solution that aligns with financial goals.

Welded steel grating is both durable and versatile. It fits well in various industrial environments. Many sectors, like construction and wastewater treatment, rely on this material because it offers safety and longevity. According to an industry report, the global metal grating market is expected to grow by 4.5% annually through 2025. This growth demonstrates its increasing importance.

In manufacturing plants, welded steel grating provides excellent drainage. The open design allows liquids and debris to fall through. This feature reduces slip hazards. Additionally, it’s easy to clean. However, some facilities might overlook regular maintenance, which can lead to rust over time. It's essential to address these issues to ensure safety.

Another key aspect is its adaptability. Welded steel grating can be customized for different applications. From walkways to platforms, it meets many needs. However, not all configurations may be optimal for every environment. For example, certain settings may require additional corrosion protection. Evaluating specific project requirements is crucial for success.

Welded steel grating offers impressive resistance to corrosion and various environmental factors. This characteristic makes it an excellent choice for outdoor projects. Steel grating can withstand harsh conditions, including moisture and chemicals. It does not easily rust, which prolongs its lifespan.

In many settings, it faces daily wear and tear. Rain, snow, or spills can lead to corrosion in inferior materials. However, welded steel grating provides peace of mind. Its structure and finish help prevent degradation. This durability ensures safety and reliability in industrial applications.

Yet, some might overlook the importance of regular maintenance. While steel grating is tough, it needs attention, especially in extreme environments. Proper cleaning can enhance its resilience. This proactive approach reflects a commitment to quality and performance. Ultimately, choosing welded steel grating for your project means investing in a product that stands up to the elements.