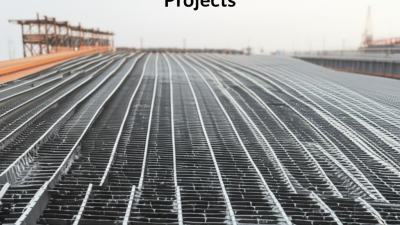

In the realm of construction and infrastructure, the choice of materials can significantly influence the durability, safety, and efficiency of any project. One material that has garnered significant attention is Welded Steel Grating. This robust solution not only offers a myriad of benefits but also caters to a diverse range of applications, from industrial flooring to walkways and platforms. The inherent strength of welded steel provides a stable and reliable foundation, making it an ideal choice for heavy-duty environments.

Furthermore, Welded Steel Grating promotes excellent drainage and airflow, reducing the risk of slip hazards and enhancing worker safety. Its versatility in design allows engineers and architects to customize the grating to meet specific project requirements, ensuring optimal performance. In the following sections, we will delve into the top ten benefits of using Welded Steel Grating in your projects, showcasing how this innovative material can elevate the quality and efficiency of your construction endeavors.

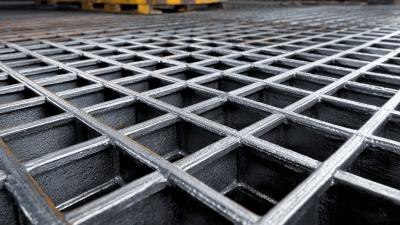

Welded steel grating presents remarkable durability and strength, making it an ideal choice for diverse construction and industrial applications. The material’s robustness is particularly advantageous in high-stress environments where traditional materials may fail. Reports indicate that the welded steel tanks market is projected to grow significantly, surpassing USD 7.3 billion by 2024, with a steady growth rate of 4% over the subsequent years. This trend emphasizes the industry's confidence in welded steel's superior performance under varying conditions.

When considering welded steel grating for projects, it’s vital to leverage its enhanced resistance to corrosion and impact. By integrating advanced materials such as high-strength steels with innovative coatings, engineers can further improve the longevity of structures like solar trackers. This approach not only ensures safety but also reduces maintenance costs, allowing for better resource allocation.

Tips: Always evaluate the specific needs of your project before selecting materials. Conducting a thorough analysis of local environmental factors can guide the decision-making process. Additionally, consider consulting industry reports for the latest data on material performance and market trends to make informed choices that can lead to successful project outcomes.

Welded steel grating has emerged as a cost-effective solution for a variety of construction projects. When considering long-term project execution, this material offers significant financial advantages due to its durability and low maintenance requirements. Unlike other flooring options, welded steel grating is less prone to damage, which reduces the need for frequent repairs or replacements. The robust nature of welded steel ensures that it can withstand harsh environmental conditions, ultimately leading to substantial savings over the project’s life cycle.

Moreover, its installation is often quicker and more efficient compared to traditional materials, which can further enhance project timelines and reduce labor costs. By streamlining the construction process, welded steel grating minimizes downtime, allowing projects to stay on schedule and within budget. The inherent design of this grating also allows for effective drainage and airflow, contributing to the longevity and functionality of the structures it supports. Therefore, opting for welded steel grating not only provides immediate economic benefits but also secures substantial long-term savings.

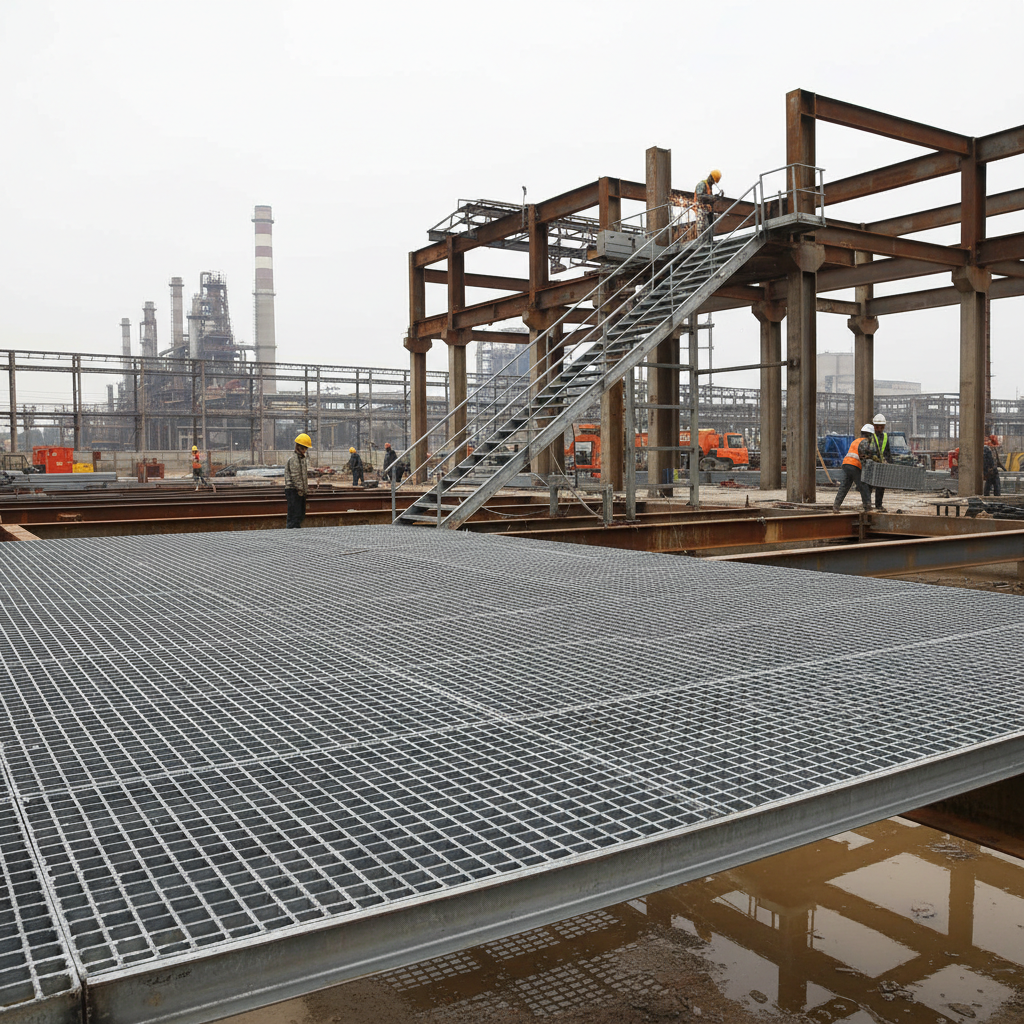

Welded steel grating offers a wide range of versatile applications across various industries, making it an ideal choice for many construction and design projects. In industrial environments, such as factories and power plants, welded steel grating provides safe and durable flooring solutions that can withstand heavy loads and harsh conditions. Its open design allows for excellent drainage and ventilation, making it suitable for areas where liquids or debris might accumulate, ensuring a safer working environment.

Moreover, welded steel grating is increasingly being utilized in architectural applications, such as walkways, platforms, and stair treads. Its aesthetically appealing and robust nature makes it a popular choice for both commercial and residential structures. With customization options available, including different sizes and finishes, welded steel grating can be tailored to meet specific project requirements. Additionally, its lightweight yet sturdy construction allows for easier installation and maintenance, further enhancing its appeal across various sectors, from transportation to agriculture.

| Benefit | Description | Applicable Industries |

|---|---|---|

| Strength | Welded steel grating can support heavy loads and withstand harsh environments. | Construction, Manufacturing |

| Corrosion Resistant | Available in galvanized or stainless steel options, offering protection against rust. | Oil & Gas, Marine |

| Cost Effective | Lower initial investment and reduced maintenance costs over time. | Retail, Utilities |

| Lightweight | Easier to handle and install compared to solid flooring alternatives. | Warehousing, Logistics |

| Versatility | Can be customized for various applications like flooring, walkways, and platforms. | Construction, Mining |

| Safety | Provides slip-resistant surfaces, enhancing workplace safety. | Pharmaceutical, Food Processing |

| Aesthetic Appeal | Modern design options that enhance the appearance of facilities. | Commercial, Residential |

| Easy Maintenance | Simple cleaning and upkeep compared to other flooring systems. | Manufacturing, Transportation |

| Environmental Impact | Recyclable materials minimize ecological footprint. | Construction, Renewable Energy |

| Durability | Long lifespan with resistance to warping and cracking. | Industrial, Infrastructure |

Welded steel grating is an excellent solution for enhancing safety features in various projects, particularly in environments prone to slips and falls. Its design allows for excellent drainage, significantly reducing the accumulation of water and other slippery substances. This feature is crucial in industrial settings, where spills are common, and in areas such as restaurants or farms, where workers face a higher risk of injuries. By using welded steel grating, businesses can effectively lower the risk of slips, trips, and falls, which, as highlighted in recent reports, are major contributors to lost work time and costly claims.

Furthermore, the robust and durable nature of welded steel grating adds an additional layer of safety. It is designed to withstand heavy loads and resist deformation, providing a stable walking surface. This characteristic is essential in high-traffic areas where safety is paramount. Utilizing advanced safety technologies, businesses can promote a culture of safety that not only protects workers but also minimizes potential liabilities. Investing in welded steel grating is a strategic move towards achieving a safer working environment, ultimately benefiting both employees and employers alike.

Welded steel grating is increasingly recognized for its low maintenance requirements and long lifespan, making it an ideal choice for various industrial and commercial projects. With a typical lifespan of over 20 years, welded steel grating significantly outperforms other materials such as fiberglass or plastic composites, which often exhibit wear and require replacement more frequently. The durability of welded steel grating stems from its robust construction and superior resistance to harsh environmental conditions, including extreme temperatures and corrosive substances. According to a recent industry report by the National Association of Architectural Metal Manufacturers (NAAMM), using welded steel grating can reduce lifecycle costs by nearly 15% compared to traditional flooring options.

Tips: To ensure the longevity of your welded steel grating, consider implementing a routine inspection schedule. This can help you detect potential issues early, such as rust or wear, allowing for timely maintenance interventions that further extend its lifespan.

Another advantage is the low maintenance necessity. Once installed, welded steel grating requires minimal upkeep, typically only needing occasional cleaning to remove debris that could obstruct drainage. Reports indicate that the cost of maintaining welded steel grating is substantially lower than maintaining other flooring systems, providing a cost-effective solution for many businesses. By investing in welded steel grating, not only do companies save on long-term maintenance costs, but they also contribute to a safer work environment with less downtime for repairs.