In the realm of industrial applications, the utility and functionality of materials are paramount, and steel grating stands out as a critical component. As renowned industry expert Dr. John Smith emphasizes, "Steel grating is not just a construction element; it's an integral part of enhancing safety and efficiency in industrial settings." This reflects the undeniable truth that steel grating provides robust solutions tailored to meet the demanding needs of various sectors, ranging from manufacturing to oil and gas.

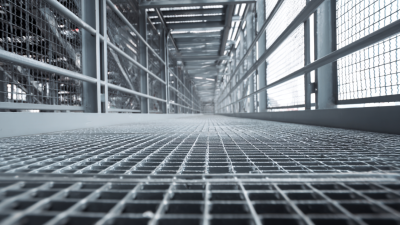

Steel grating's features—such as its strength, durability, and ability to facilitate drainage—position it as an invaluable asset in ensuring both operational efficiency and workplace safety. For instance, its lightweight yet sturdy design allows for easy installation, while simultaneously providing excellent slip resistance underfoot, crucial for busy industrial environments. Thus, the benefits of using steel grating extend beyond mere functionality, influencing factors such as maintenance costs and worker safety standards.

As industries continue to evolve, the significance of incorporating high-quality steel grating will only grow. By embracing this versatile material, businesses can enhance their operational frameworks, ultimately leading to a more productive and secure work environment. The following sections will delve into the myriad advantages of steel grating, showcasing why it remains a top choice for industrial applications.

Steel grating has become a crucial component in various industrial settings due to its numerous advantages. One primary benefit is its durability; steel grating can withstand heavy loads and harsh environmental conditions, making it ideal for factories, warehouses, and outdoor applications. This resilience leads to lower maintenance costs over time, as fewer replacements or repairs are needed compared to other flooring materials. Additionally, steel grating provides excellent drainage capabilities, reducing the accumulation of water and debris, which is vital in preventing slip hazards and maintaining safety in the workplace.

Tips for selecting steel grating include considering the load requirements specific to your application. Ensure that the grating's load-bearing capacity matches the needs of your facility to prevent any structural issues. Furthermore, you should evaluate the type of finish applied to the steel, such as galvanization, which can enhance the material's resistance to corrosion and extend its lifespan significantly.

Another notable benefit is the versatility of steel grating. It can be customized to various sizes and shapes, making it suitable for numerous applications—from walkways and platforms to safety barriers and stair treads. Its open design not only allows for adequate airflow and light penetration but also facilitates easy cleaning and maintenance. In industrial environments where hygiene and efficiency are paramount, these characteristics can lead to improved overall performance and worker safety.

| Benefit | Description | Application Areas |

|---|---|---|

| Durability | Steel grating is highly resistant to impact and wear, ensuring a long lifespan even in harsh environments. | Manufacturing plants, warehouses, and outdoor installations. |

| Cost-Effectiveness | Although the initial investment may be higher, the longevity and reduced maintenance costs make it an economical choice. | Industrial sites, commercial buildings. |

| Safety | Provides excellent slip resistance, reducing the risk of accidents in workplaces. | Construction sites, factories, and power plants. |

| Versatility | Available in various sizes, shapes, and materials, allowing customization for specific needs. | Marine, automotive, and aerospace industries. |

| Ease of Installation | Lightweight and designed for quick installation, reducing downtime during setup. | New construction projects and retrofitting existing structures. |

Steel grating has gained popularity in various industrial applications due to its exceptional durability and load-bearing capacities. Constructed from high-quality steel, these gratings are engineered to withstand harsh environments and heavy loads, making them ideal for manufacturing facilities, warehouses, and transportation systems. The design of steel grating provides a robust solution that can tolerate the wear and tear associated with industrial settings, ensuring longevity and reliability in operations.

The load-bearing capabilities of steel grating are particularly noteworthy. It is specifically designed to distribute weight efficiently across its surface, reducing the risk of deformation or failure under heavy loads. This makes it a preferred choice for walkways, platforms, and support structures where safety and structural integrity are paramount. Moreover, the open design of steel grating allows for effective drainage and ventilation, further enhancing its performance in demanding conditions. As industries continue to seek materials that offer both strength and functionality, steel grating stands out as a top choice for durable and reliable applications.

The use of steel grating in industrial applications offers a notable advantage in terms of cost-effectiveness over the long term. Unlike traditional flooring materials, steel grating is designed to endure harsh environments and heavy loads, minimizing the need for frequent replacements or repairs. This durability translates into significant savings; companies can allocate their budgets more effectively, directing funds toward other critical areas instead of recurring maintenance of infrastructure.

Moreover, the installation of steel grating can lead to reduced labor costs. Its lightweight yet sturdy design allows for quicker installation compared to heavier alternatives, decreasing the time required for setup. Additionally, the open design of steel grating promotes better air circulation and drainage, which can lower the costs associated with water damage and related repairs.

By investing in steel grating, businesses not only improve their operational efficiency but also position themselves for long-term financial benefits. As operational costs decrease and the longevity of their infrastructure increases, steel grating emerges as a wise investment for any industrial setting.

Steel grating has emerged as a preferred choice for industrial applications, and its safety advantages are particularly noteworthy. One of the key features of steel grating is its slip resistance, which is crucial in environments where hazards can lead to severe accidents. According to a report from the Occupational Safety and Health Administration (OSHA), slips, trips, and falls account for over 25% of reported workplace injuries. The design of steel grating, with its open surface, allows for excellent drainage, significantly reducing the likelihood of slip incidents in wet or oily conditions.

Moreover, the visibility of steel grating enhances safety by making potential hazards more apparent. The lightweight, open structure allows for better light transmission, which can illuminate the workspace effectively. A study from the National Safety Council highlighted that increased visibility in work areas correlates with a 30% decrease in accidents. Choosing steel grating contributes to an overall safer working environment by minimizing both slip risks and enhancing visibility.

**Tips:** When selecting steel grating, consider factors such as load capacity and surface finish to maximize slip resistance. Regular maintenance, including cleaning to remove debris and spills, is essential for maintaining its safety features. Additionally, installing grating in critical areas like walkways and workstations can further enhance safety measures in industrial settings.

Steel grating is an increasingly popular choice in industrial applications, primarily due to its durability and versatile functionalities. When it comes to environmental considerations, the recycling potential of steel grating stands out. Steel is one of the most recycled materials globally, which means that old or damaged grating can be melted down and repurposed, minimizing waste. This aspect not only conserves natural resources but also reduces the carbon footprint associated with the manufacturing of new materials. Opting for recyclable products like steel grating aligns with sustainable practices and fosters responsible industrial operations.

Another crucial environmental consideration is the lifespan of steel grating. With proper maintenance, steel grating can last for decades, significantly outpacing many alternative materials. This longevity means fewer replacements are required over time, leading to less material being consumed and less waste being generated. To maximize the lifespan of steel grating, it's advisable to perform regular inspections and maintenance checks. Addressing any wear or damage promptly can prevent more extensive problems down the line and ensure the continued sustainability of the structure.

Tips: Consider incorporating steel grating systems in areas with heavy loads or corrosive environments, as they provide both strength and resistance. Additionally, look for options that feature surface treatments to enhance durability and safety, further extending their lifecycle while contributing positively to the environment.