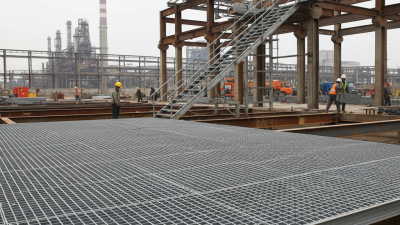

Press Welded Steel Grating is becoming increasingly popular in various construction projects. Its design allows for better weight distribution and strength. This type of grating often provides advantages over other materials.

One key benefit of Press Welded Steel Grating is its durability. It stands up well to heavy loads and harsh environments. This makes it ideal for industrial settings and walkways. Also, it’s resistant to corrosion when coated properly.

Another important aspect is its safety features. The slip-resistant surface enhances traction. This reduces accidents and increases overall safety for users. However, depending on your project, sourcing quality material can be a challenge. It’s essential to evaluate the supplier's reputation to ensure you get the best product for your investment.

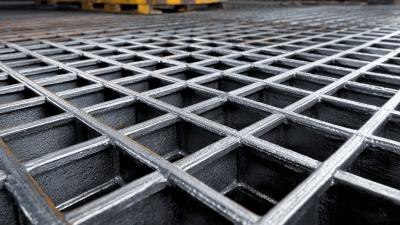

Press welded steel grating is a critical component for structural support in various projects. It provides a strong, durable solution for flooring systems, walkways, and platforms. According to a recent industry report, steel grating can support weights up to 1,500 pounds per square foot, making it suitable for heavy-duty applications. The design and manufacturing process of press welded steel grating involves fusing steel bars at high temperatures, resulting in a robust product with minimal deformation under load.

One significant benefit of press welded steel grating is its corrosion resistance. Hot-dip galvanization or protective coatings enhance longevity, especially in harsh environments. A study showed that projects using galvanized grating experienced a 70% reduction in maintenance costs over 10 years compared to non-galvanized alternatives. However, some challenges exist; installation requires careful alignment and planning. Inattention to detail can lead to misalignment, compromising structural integrity.

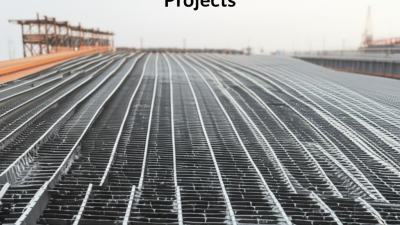

The grating's open design promotes excellent drainage and airflow. This feature is particularly advantageous in industrial settings where spills and debris are common. Yet, it can hinder safety if not properly evaluated. Grating with larger openings may pose slipping hazards. Thoughtful consideration of the application environment is necessary to maximize benefits while minimizing risks. Proper training for installation crews can also help address these concerns.

Press welded steel grating is gaining traction in various industries due to its cost-effectiveness. According to a recent industry report, using steel grating can reduce overall project costs by up to 30%. This is mainly due to its durability and low maintenance requirements. With minimal upkeep, companies save significantly on long-term expenditures. Steel grating’s lifespan typically ranges from 20 to 25 years, depending on the environment. Thus, initial higher expenses can easily convert into savings over time.

Moreover, the versatility of steel grating contributes to its financial benefits. It is lightweight yet strong, making it easier to handle and install. This feature can reduce labor costs significantly. A report from the American Institute of Steel Construction indicates that labor costs can account for as much as 50% of total project expenses. Choosing lighter materials can thus lead to substantial savings. However, while steel grating is robust, it is essential to assess specific project needs to avoid overengineering or underutilizing resources. Balancing strength and application is critical for maximizing cost-effectiveness.

| Benefit | Description | Cost-Effectiveness |

|---|---|---|

| Durability | Steel grating is resistant to corrosion and impact, ensuring longevity in harsh environments. | Lower maintenance costs and longer replacement cycles lead to savings. |

| Safety | Provides slip resistance and strong footing for both workers and equipment. | Reducing accidents saves on liability and insurance costs. |

| Versatility | Can be used in various applications, from flooring to walkways and platforms. | Reduced need for multiple products can lower overall project costs. |

| Lightweight | Less weight translates into easier handling and installation. | Lower transportation costs due to reduced weight. |

| Customizability | Can be manufactured to meet specific project requirements. | Custom solutions can prevent costly modifications later. |

| Aesthetic Appeal | Offers a clean and modern look for both exterior and interior applications. | Enhances property value via improved aesthetics. |

| Environmentally Friendly | Recyclable materials reduce environmental footprint. | Potential tax benefits for using eco-friendly materials. |

| Easy Maintenance | Requires little upkeep, mainly cleaning. | Saves on labor and material costs over time. |

| Ease of Installation | Quick setup reduces labor costs significantly. | Fewer hours of labor translates to financial savings. |

| Increased Load Capacity | Designed to handle heavy loads, ideal for industrial applications. | Minimizes the need for additional support structures, saving costs. |

When it comes to project safety, slip resistance is a key factor. Press welded steel grating offers superior traction, reducing the risk of falls. According to industry reports, properly designed grating can increase slip resistance by up to 50%. This feature is crucial in environments like factories, warehouses, and outdoor settings. Ensuring safety in these areas helps protect workers and minimizes accidents.

Load capacity is another significant benefit. Press welded steel grating can support substantial weight, often exceeding 1,000 pounds per square foot. This strength makes it suitable for heavy machinery and foot traffic. The structural integrity of this grating type ensures durability, even in harsh conditions. Ensuring that the grating chosen fits the specific weight requirements of your project is essential.

Tip: Always check the manufacturer's specifications for slip resistance ratings and load capacity. Understanding these factors can prevent costly mishaps.

Tip: It's vital to assess your project’s specific conditions. Wet and oily surfaces may require different grating design considerations. Adapting to these environmental factors can be beneficial.

When it comes to construction materials, longevity is crucial. Press welded steel grating is known for its impressive corrosion resistance. This feature significantly extends its lifespan, making it an ideal choice for various projects. In environments with high humidity or exposure to chemicals, this type of grating performs particularly well. Users often find that it requires less maintenance over the years, reducing overall project costs.

The resilience of press welded steel grating stems from its design and materials. The welding process ensures that each piece is structurally sound and tightly bonded. However, improper installation can still lead to issues. Additionally, while the corrosion resistance is excellent, it is not entirely foolproof. Continuous monitoring and timely inspections can help catch any signs of wear early on.

Choosing press welded steel grating involves understanding both its benefits and its limitations. It offers durability that many materials simply cannot match. However, this does not mean it is maintenance-free. Ensuring the integrity of the grating requires consistent attention. This responsibility may deter some users who prefer a set-it-and-forget-it approach.

Steel grating finds use in various industries due to its durability and strength. Manufacturing plants rely heavily on it for flooring and walkways. It withstands heavy loads without bending. This capability is essential in environments where safety is a priority.

Another area benefiting from steel grating is construction. Builders use it for temporary walkways and support structures. Its lightweight nature allows for easy setup. Additionally, maintenance crews often appreciate its slip-resistant properties. This makes it ideal for both indoor and outdoor applications.

Transportation hubs also utilize steel grating. Airports and rail stations require robust materials for their platforms. Steel grating allows for efficient drainage, reducing water accumulation. However, it may need regular inspections to ensure it remains safe over time. The visible wear can be a concern, highlighting the need for periodic checks. In industrial settings, balancing cost with safety is often a reflection of project planning.